I need to slow down my laser gantry to a feed rate of 5 mm/min. My understanding is that GRBL has a “standard” minimum feed rate of around 45 mm/min. However, the latest version allows the use of extended ASCII commands to over ride the existing feed rate. I need to send the extended ASCII “0x92” that will decrease the existing feed rate by 10%. I thought I’d write a Macro that will send that extended ASCII, but not sure how to do it. Can anyone here help? Thanks!

I’m not certain but it’s possible these are the commands already sent by the speed and power adjustments that are found in the Move window once a burn has started.

What are you doing that requires such slow rates?

If you have very specific requirements it might be worthwhile compiling a custom version of the firmware to meet your specific needs. Don’t know how easy X-Carve makes this but a quick lookup reveals that the X-controller may be using a standard Arduino Uno with GRBL? If so, that should be fairly straightforward to compile this or find a pre-compiled version that meets your needs.

Found this guide from Inventables about how to reflashing Grbl to X-Controller. It links to their fork of Grbl and gets you started with the Arduino IDE.

[EDIT] - Forgot to add the link:

How do I re-flash Grbl to my X-Controller/Arduino? – Inventables (zendesk.com)

Looking at the source code for the fork it looks like it’s literally just commenting out one line in config.h to disable AMASS.

Excellent…thanks!

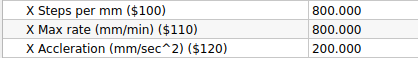

I was able to get the most recent fork and find/comment out the line implementing the AMASS algorithm. I’ve used the Arduino IDE to flash the old G-Shield so that should go OK. After adjusting the $100, $101 and $102 values I hope to get a true feed rate of 5 mm/min. I need this slow speed to cut 0.5mm brass using a DPSS laser in one path. The manufacturer says it’s possible and has videos to show it being done. My limitation has been the inability to get my X-Carve to go that slow.

You should not need to adjust these values if you disabled AMASS. Adjusting these will mess with your stepper calibration. Speed settings alone should get you to the 5mm/min.

Wow. That should be interesting. Keep us updated how this goes.

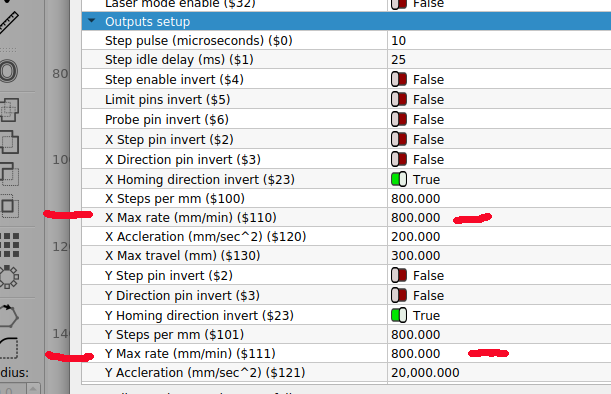

I think you can set the ‘speed limit’ for an axes in the ‘Machine → Settings → Output setup’

These values are in ‘units’, not mm/s or mm/m…

Mine are set to not exceed 800mm/s. If your machine is set to mm/min this value reflects whatever ‘unit’ you have set. If I set mine to ‘inch’, by exiting the machine settings, click units to inches. Go back to machine settings and ‘read’ the controller back, it will be 800mm/min

Change the axis to whatever the fastest speed you want it to attempt.

![]()

Well…commenting out the “AMASS” line in config.h solved the speed problem. I can now run my machine at 5 mm/min. Unfortunately, it also, somehow, messed up how the laser works since it now pulses on and off instead of staying on constant power (which is checked “on” in LB). So, it looks like I solved one problem only to be presented with a new one. Not sure where to go from here???

This is probably due to variable power trying to scale for low speeds.

Try enabling “Constant Power Mode” on the cut setting to disable this feature.

Yes…“Constant Power” was already set to “on”.

Does the laser behave normally at higher speeds? If not, then perhaps something else going on with the new firmware.

Check the other GRBL settings. The firmware update should keep your existing settings but they may have gotten overridden. Especially look for $32=1 to be on.

Thanks for the suggestion! The laser works as expected at higher speeds. I started at 50mm/min and reduced the speed by 10mm/min for each iteration and the pulsing I saw at 5mm/min only started to appear at 10mm/min. I’m going to try a cut at 10mm/min and make several passes to see if that’s a viable way to go.

I’m curious what’s going on at lower speed. I’m guessing yet another potential configuration change. But glad you’re able to test at the higher speed.

At 10mm/min I was able to cut through 0.5mm brass in 5 passes. That’s not bad! The cut is very clean on the bottom. It’s hard to tell what’s actually going on with the laser. It LOOKS like it’s pulsing on/off, but maybe it’s just the studder steps of the stepper motors at such a low speed that makes it appear that way???

Nice!

Oh… interesting. Really not sure. Might be worth experimentation. If you have a scope would be interesting to see what’s coming out of the controller too.

I don’t have a scope and my knowledge of electronics is very thin. I’m in contact with the manufacturer of the laser and am awaiting input from them about all this.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.