Hello all, I dont have a Laser yet (still researching) but would like to know if material hold is a common thing when cutting ? I have a cnc and material hold is a big deal when cutting.

Thanks in advance

Tim

Mostly no. There’s no force trying trying to push things around like when shoving a tool bit through material. There may be times when things need a little hold down to keep them from blowing around under the stream of air from the cutting nozzle.

They’re useful when your material won’t lie flat.

Like bowed ply and leather. For leather I have a piece of 6mm mdf with a cutout in the middle of 600x600. I put the leather on a board, put the second board over the top and use clamps that hold on to my honeycomb. I have a few sacrificial boards for difficult mounting, that will take double-sided tape, carpet tape, etc. so rarely use the clamps. I have some 2/3kg weights and some heavy granite tiles I use for low-profile weighting, too. You just have to be careful with the tool path. I run a frame without anything tightened down, so you don’t break anything. Once the path is clear, I tighten it up and run the job.

The other reason clamps are useful is if you have parts that may tip over balanced on a bed rail, and the head can catch the cut piece and move the material - clamps help it with light touches that might otherwise ruin a job and just flick the part into the bin beneath.

I’m going to make some fittings with 2.4mm, 3mm slots that you slide material in that holds it all around, for when you want to not get reflection burns, I will have supports to match at the relevant heights to keep the material flat and to allow parts to drop onto the honeycomb.

I don’t use the honeycomb much.

A recent Lightburn video showing the magic of print and cut provides a bit of insight to securing one’s work piece. A drop-out levered itself in such a manner as to shift the entire work piece, creating a misalignment. Had the piece been secured in any way, it’s likely the drop-out would not have caused the fault. If the work piece is on a flat surface, that won’t be a problem, but elevated work could shift.

I am using magnets to hold down my leather, they are a little bigger than a quarter and about 1/4 inch thick with 80 lb pull. I have a steel honeycomb bed. They work great.

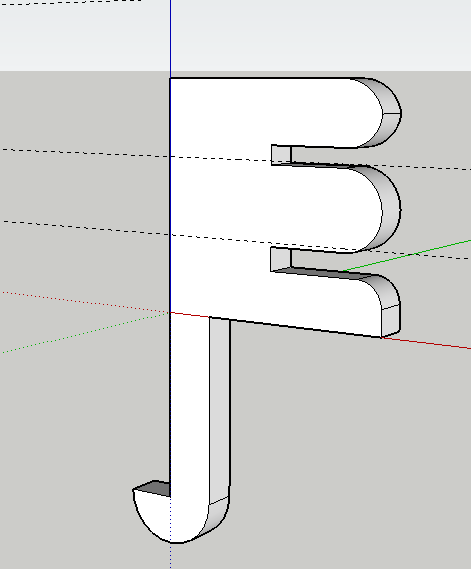

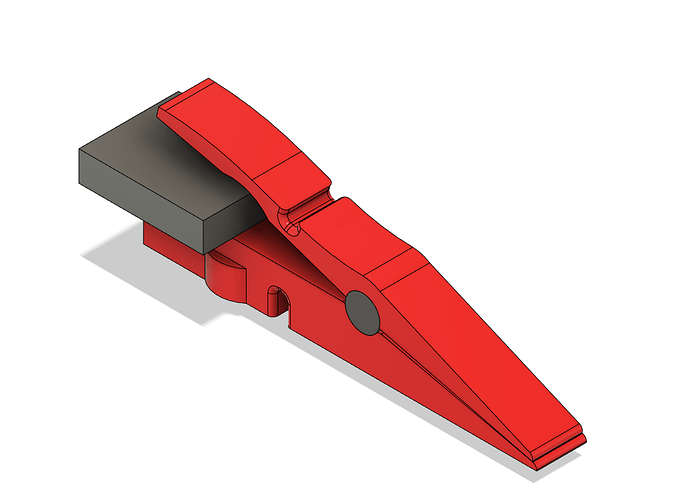

I use a lot of 6mm plywood in projects and that is almost never flat. I also have a steel plate on the bed and support work with 10mm high magnets. I designed these “pegs” that are 10mm high to the lower jaw and will open to take 10mm thick material. I designed them to not ever be more than 4mm above the job as my focus height is 4.5mm so no problem with the risk of collision with the nozzle. They have a strong magnet in the bottom part and the closing force is enough to hold the plywood flat.

Hope that helps.

David