I have two xTool D1 Pros, a 20 Watt and a 40 Watt. I developed my materials library for the 20 Watt, and now I would like to use it with my 40 Watt. Ideally, I would like to use a common library for those cuts that can be made on either machine, but the laser powers are specified as a percentage of full power. Is there an easy way to do this?

You can duplicate all your settings individually from the material library in the one machine and edit the settings and names. Depending on how many materials you have, you can either save the individual materials in the same material library with the corrected settings and the new name, or copy the entire library and give it a new name and correct settings afterwards, (I will do that) then you just load the library when you work with the other machine.

I have some 60 or 70 individual materials/cuts in my library, and simply replicating them all and editing them is not what I was looking for. It would be a configuration nightmare keeping them synchronized as I might tweak them. I don’t want two libraries, and I don’t want one library with double the entries, one set for the 20 and another set for the 40 Watt.

Explain to us what you want, somewhere you will have to make choice of which laser.

If you’re looking for a software solution to modify all the power parameters, I don’t know of one for the normal laser library.

Might be able to do it with an xml editor.

Good luck

![]()

In the time you have been looking for an alternative to edit 60-70 materials (impressively many) manually, I will have made the first 20 changes for a modified library. After all, only 2 values must be changed per material. It’s a one-time occurrence, so get over it. ![]()

And that’s exactly what I did: I imported my 20W material library into Excel (which can import .xml files), and wrote a macro to automate the process a bit. The macro changes the power percentage or the speed or a combination of those parameters to maintain the Joules/mm of the cut, the fundamentally important parameter for lasing. I wrote the macro to go either way (20 to 40 Watt or 40 to 20 Watt). I constrain speed to 300 mm/sec, and obviously constrain percentage to 100%. So far, flawless results.

It’s a one-time occurrence,

Bernd…No, it’s not. I have an increasing number of contacts from others doing lasing with various power lasers, and material library sharing is always being done.

Out of curiosity, where do you get these values?

I have a spreadsheet of pules/mm at different pulse/frequency values. This is based on the output of the JPT MOPA 60W source manual, I believe.

![]()

So it makes sense ![]()

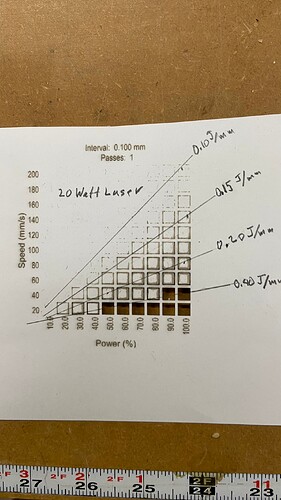

If you are asking about Joules/mm, I take the laser max power in Watts and multiply it by the % power setting, then divide it by the speed in mm/sec. That yields the actual energy per mm being delivered to the target in Watt-sec/mm. One Watt-sec is a Joule. Here’s a material test with lines of constant J/mm, and you can see that the result is about the same along those lines.

If you are asking about our specific material library values, we got those the old fashion way: many, many tests on various target materials until we got results we liked. They are owned by a cooperative of laser owners who have banded together as a business, so I’m not at liberty to share them.

Is there some reason that the bottom right six squares and two above it very so much in appearance?

I’d think you’d want a square mm, not a single line…

Thanks for the explanation.

Couple quick questions… are both of these lasers visible light frequency?

Can you just swap them back and forth…

Tried to read the documentation on them, but they implied you had to make a board change, then homing didn’t work… it was kind of confusing…

![]()

I was just doing a cut test on 110 Lb. card stock. Those bottom eight squares fell out when lifted off the mesh, so you’re looking at the table below, shadowed somewhat.

Both lasers in question are xTool diode lasers, IR I presume (hard to find out their exact nm on their website). Both lasers we were using initially were xTool D1 Pro 20 Watt, but the other guy bought a new 40 Watt head for his, and that’s what we were playing with. He ran two comparison material tests, one where he halved the power, and one where he doubled the speed (chickened out and only went to 300 mm/sec). They both looked very similar.

And I recognize that preserving J/mm is just a first order starting point. We both continue to tweak things in our libraries as we learn about things.

Hi.

Re: xTool wavelenght, the 20W is advertised as 455nm, and since the 40 W uses the same laser units (8 vs 4), I’d assume its the same.

I don’t know whether the power meter I recently purchased will display the wavelenght (I suppose it won’t), but it’s on the visible spectrum anyway.

I did have the 40W unt in the cart on the launch day pre-sale, but chickened out as at that point I had not yet figured out why i couldn’t get the XCS to work, and hadn’t started the LB trial yet.

Th only IR laser from xTool that I know of, is the 2W 1064nm unit.

Since I have both (20W & 2W and in the future perhaps the 40W), I would like to see some kind of a solution to the original topic as well.

While I do perfectly understand why Co2 or fiber users for example wouldn’t benefit from such a feature at all, us diode laser users with easily swappable laser units (and the relatively low cost of multiple machines for that matter), would benefit greatly from such a feature IMO.

The material library sharing Jack mentioned, is also an area where I for one would see it being beneficial, simplifying the workflow.

After all, most of us just want to create laser cut or marked items/parts -whether that’s for hobby or profit- as efficiently as possible, not battle with the software or the machine.

Obviously there will always be the element of the need for workarounds present when pushing the limits of what’s available and what’s not (yet ;)) in every field of DIYism, but that’s a great thing IMO, and the eventual solutions benefits us all.

Regards,

Sam

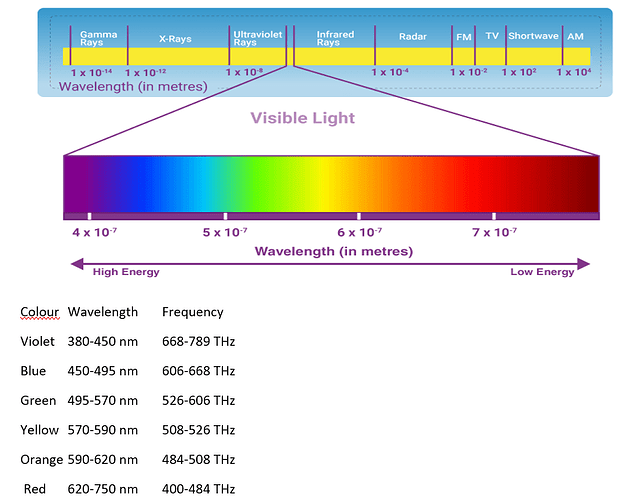

Thanks for the clarifications. So the xTool D1 diode lasers shine blue:

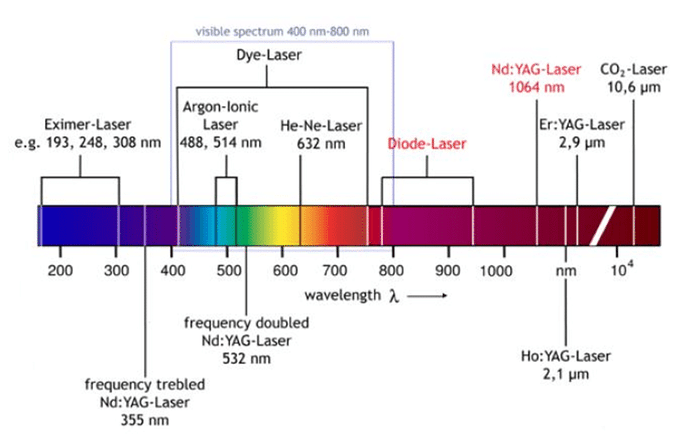

As I understand it, CO2 and fiber lasers are infrared.

True, the fiber is about 10X the frequency of a CO2 laser, but it’s a large enough frequency change that it has a quite different effect on wood and goes right through glass.

The frequency change from the co2 to fiber is enough that fiber is known for man made materials and co2 for natural material… Of course there is a bit of overlap, such as co2 cuts acrylic very well, not really a natural material… Fiber will mark wood, rather poorly…

I understand my JPT monitors what is reflected back into the source and can limit it if it’s too high… I sizzled a lens trying to mark SS with the co2. It reflects back into the device. Most metals a high reflectivity… aluminum molecule reflects over 95% of the light. This is why I wondered about the 40W frequency of the module.

Thanks for the frequency layout… here’s a little broader frequency range chart. The red Nd:YAG-Laser is my fibers frequency.

![]()

Great chart, thanks. It was mentioned above that the xTool diode lasers are spec’ed at 455 nm, but the chart shows the diode range much higher (factor of 2, ie. a second harmonic device?). I’m sure some of the lasers shown in the chart are well outside the hobby category in price/footprint. Still, it’s nice to learn about them.

Keep in mind the longer the wavelength the lower the frequency…

Have fun

![]()

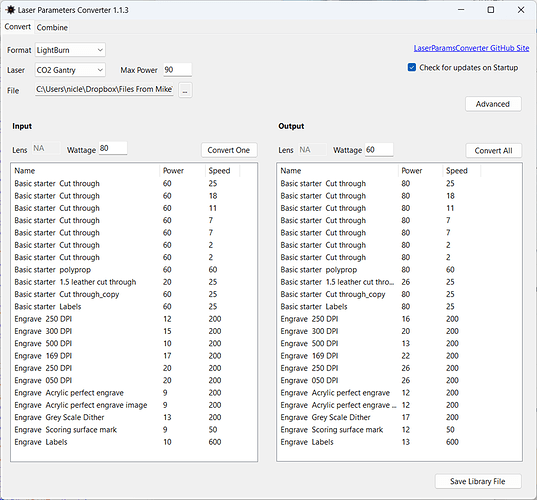

I know it’s not exactly what you are asking for (doesn’t combine .clb files), but there is a useful tool in this space called “LaserParamsConverter” by David Christian.

Designed primarily to convert libraries from ezcad to LB, but can be used LB to LB to re-scale power settings.

E.g. to create a new 60w library from an existing 80w library;

It and EZCad2 both need a Windows os… I looked at them before… it doesn’t do as well going to a higher power…

![]()

I think I understand. If you would allow me to download your list ( I have the same setup) I will try to fix it

Could you share the Excel macro that you wrote for the more mathematically challenged of us on the forum?

Thanks

Jerry Kornbluth