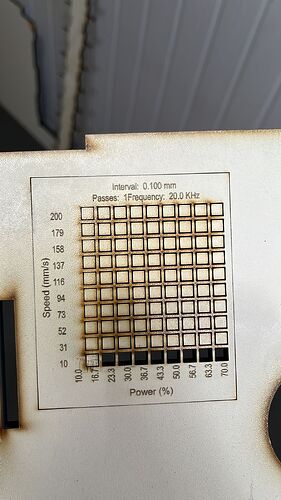

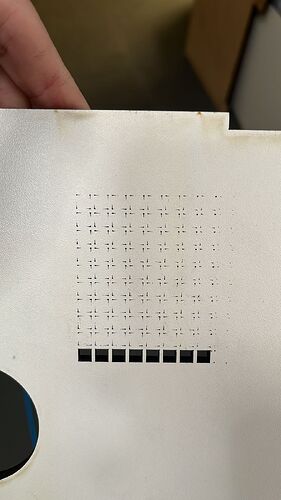

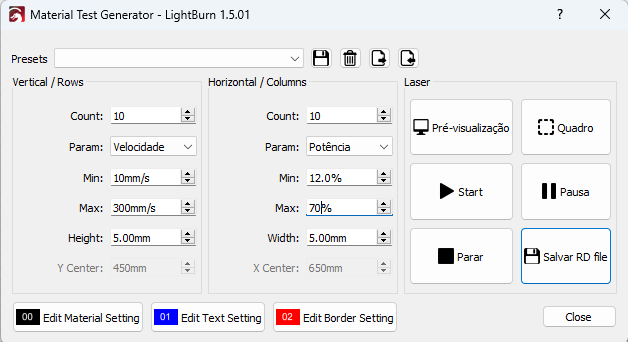

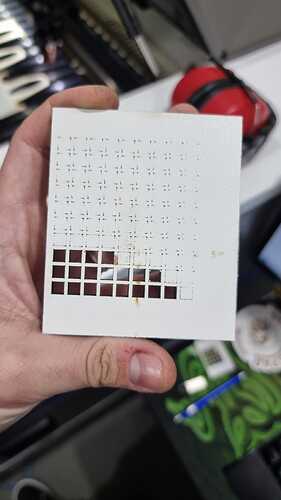

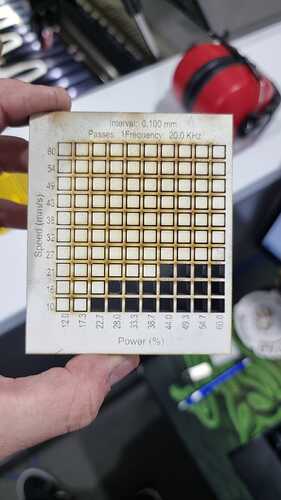

Hi, I’m trying to do a material test, as you can see in the photos, only the line with the lowest speed cuts, but in the rest of the test, it seems to have the same power

It could indicate an error in your test settings, try looking at them one more time.

Nothing unusual to see, try saving the file and uploading it here.

teste mateiral.rd (46,3,KB)

Can you try running this file?

It’s just to see if it’s the machine or the test file that doesn’t fit.

Powermax is reduced to 55% and material is 3mm MDF

lilletest.rd (23.0 KB)

Depending on what you test is your speed jumping reasonably high, finding a cutting speed for 3mm wood or MDF, eg, should stop at about 50-60 mm/s, I would think, but, not quite sure with your 130 watts

It looks more normal. What does your ammeter show in mA?, does it roughly match what you put in % in LB? - proportional to your tube?

70% power, the ammeter is at 30

Has the machine been ok before?, or is it brand new?

For a 130 Watt machine, it should be able to handle it with approx. twice as much as my 60 Watt machine (…both values are nominal, I know…).

Is it 6mm wood?

If you do the last test with a spread of 10 to 40 mm/s you will get a more detailed view of this material. You can of course increase the max power to what you think is your max. 80%?, I don’t know, I drive my tube relatively conservatively but have also had it for many operating hours.

I bought the new machine about 3 months ago. yes, 6mm MDF. There is a label that warns you not to exceed 32mA

Its a gweike lc1390n 130w

When you are more familiar with your machine, you can do a “max power” test. It involves finding the breaking point for the tube where there is no longer an increase in output power due to the increase in input power. It can be advantageously made in thick acrylic but also in thick wood. With acrylic, it’s just mostly visible.

I found out that my tube’s power curve became flat after 70%, corresponding to approx. 18mA. My personal max for my tube is 16 mA.

iil try to find the point I noticed that my table is uneven, but I don’t know how to level it

Let me add a couple items…

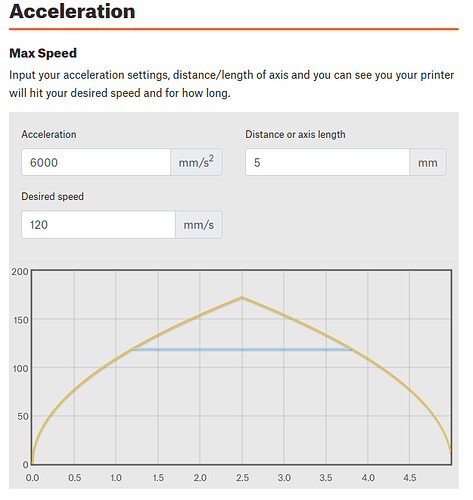

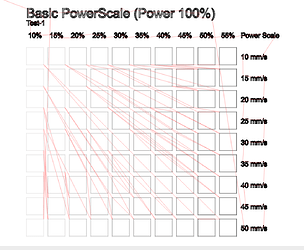

The machine, in all likelihood cannot make the speeds you’re asking for in such a short distance.

Assuming 6000mm/s^2 acceleration it will take about 7.5mm to reach 300mm/s and the same amount to slow down. This is larger than your squares of 5mm.

Even at 120mm/s speed, it will take 1.25mm to get to speed and the same to slow down. Only the blue line area will be at speed in the allocated distance of 5mm

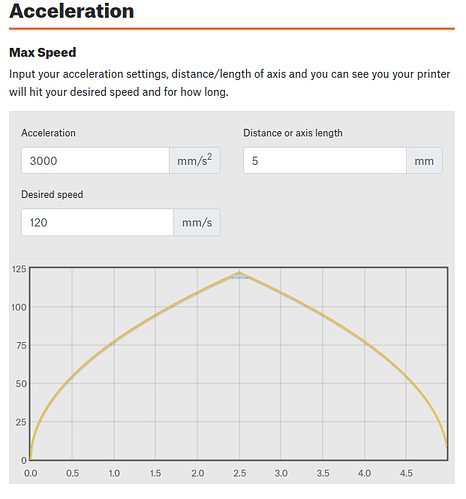

If you compute the same for an acceleration of 3000mm/s, a more common acceleration value, it’s twice as long The short line at the 2.5mm mark… or at speed for less than 1mm of the cut/engrave distance.

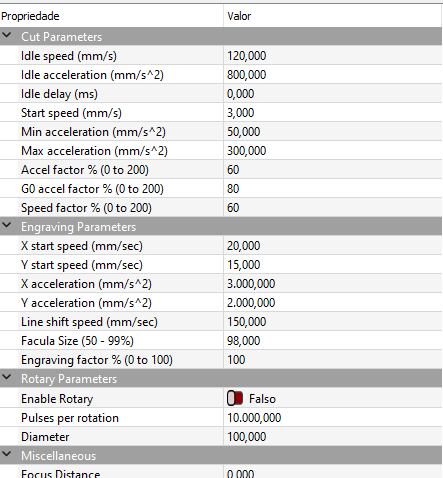

Using a minimum power might also be an issue at low speeds. Ensure your start speed in the Ruida is low enough for the min/max power setting to work. Commonly these are set to 20mm/s, mine are at 5mm/s.

While you are there, check your acceleration values for both axes… Commonly the Y axes has less as it usually carries more mass.

Make sense?

Good luck

![]()

You can use Lightburn PowerScale Generator - O2 Creative to generate your more individualized tests. The advantage, in my opinion, is that you have the direct possibility to adjust or delete some values you do not want tested. (eg there is no point in testing 3mm wood with 10mm/s and max power…to see if it cuts)

@jkwilborn addresses a “general” understanding problem that many of us have or don’t realize or just ignore.

Finding the “right” speed is just as important as finding the right power setting, both parts are actually inextricably linked.

If you want to see how fast (mechanically) your machine can move efficiently, then you make an array of small items, just like in the power test, and mark a row to test it at different speeds manually. The Ruida controller has the advantage that it has a built-in automatic stopwatch that counts the project time. From a certain, relatively small speed value, time starts to grow instead of getting shorter.

It is possible that there is a misunderstanding about speeds. I meant they apply speeds to the material test. That your machine is pre -configured correctly, I assume. Whether you want to fine tune the settings here in your window shown or not is up to your taste.

I mean the speeds of the material test should be “predefined”, in relation to the experiences one has with the different materials and the power options your machines have.

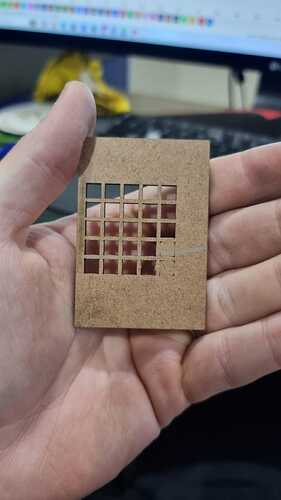

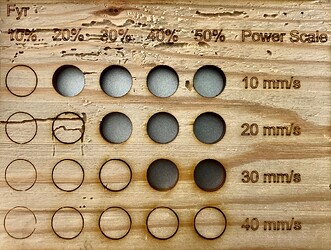

Today I had to make some signs in old untreated Pine Wood 4.8mm, to find the necessary speed I made a “quick test”, 4x5 objects with values within what I tread should be fairly appropriate.

It turned out right, the possibilities of cutting this material on my machine are within 20% power and 10mm/s and 50% power and 30mm/s. That is, in this area I can cut this material, I just have to decide what I think is best. The quality is the same in all parties that have fallen freely. I choose the golden mid, 40% and 20mm/s. Why? Just a feeling … Fits my needs … Should I make a series with 1000 pieces I will choose 50% 30mm/s or 65% (approx. 16MA) and 25mm/s, the machine can handle it well.

I hope it solves a little of what written, if not you may come again.

please no comentarers about the worm holes ![]()