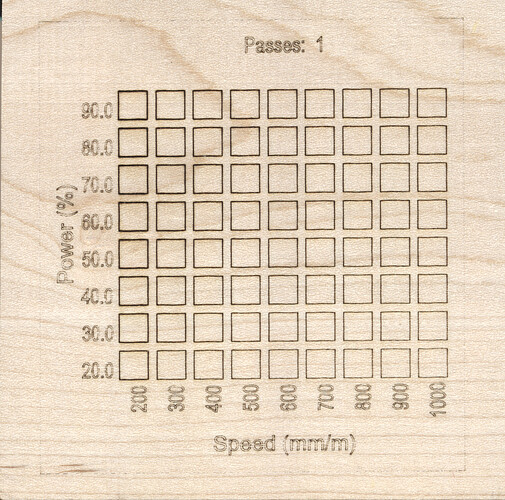

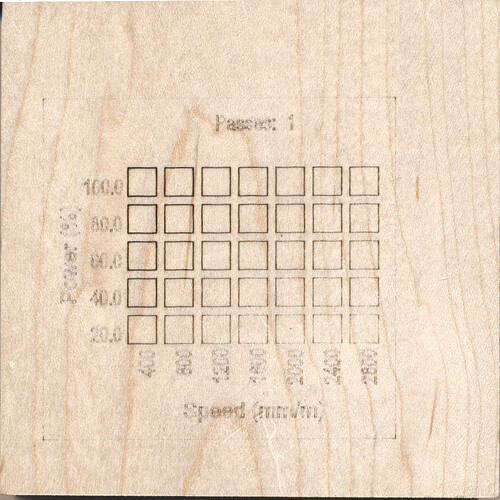

I set up a material test and the result shows very little changes between settings, it looks fairly uniform. I expected to see a range of dark squares to light squares. I’m trying to decide what range of settings I might try next. I have the Sainsmart 3018 PROVer with a 5.5W laser.

In the Test Dialog, click edit aterial Setting and change from line to fill. That will give you engraving of the squares, the way it;s set it is only running the outline of the squares. The test you ran would be for cutting and with a 5 watt laser you will need t oslow down consideraby and probably run multiple passes in order to cut.

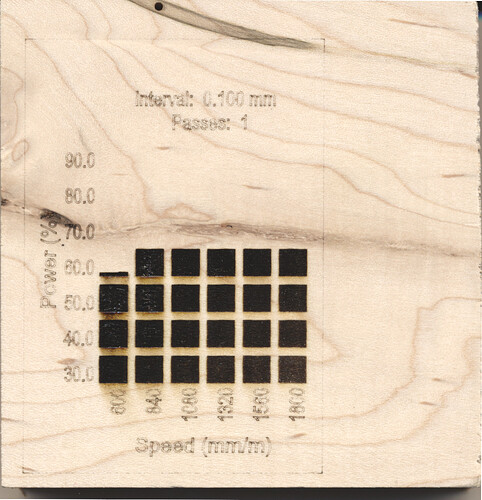

I changed my setting to fill and I discovered the lowest power setting and the highest speed was filling the square dark. I increased the top speed from 1000 mm/m to 1800 mm/m and decided to increase the steps between samples. I still got fairly uniform output. I wonder if there are other settings I should check.

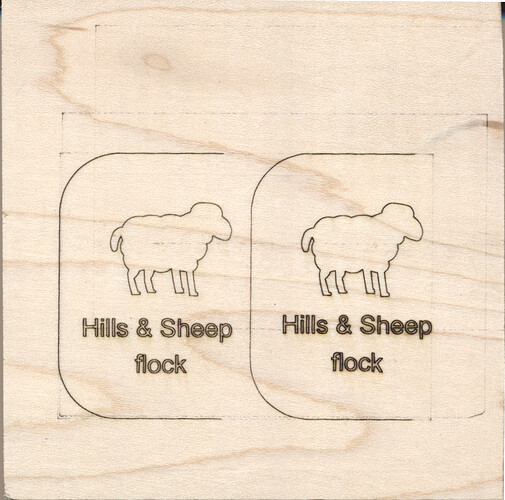

I decided to try an example of a graphic from my project. I set the speed at 600 mm/m and varied the power (20%-80%) for all of the outlines, icons, and text. I can see slight variations. I can also see the 1% power outline of the Frame function.

Try running at higher speeds for engrave. Run 1500 - 6000 and see what you get. If still no difference, do the following. In the console window type $$ then hit enter. Copy/Paste the entire output here and post a screenshot (not a cell phone pic) of your entire Lightburn screen with a project loaded and the Cuts/Layers Panel and Laser Panel visible. Also post a screenshot of the Settings Window (Gears icon) with the Units and Grids tab visible and post a screenshot of the Device Settings Window (Wrench and Screwdriver icon).

Thanks, I plan to try a higher speed setting range for my next test. I read my machine is capable of 2250 mm/m based on the $100 parameter which is 800 steps per mm. My next test will exceed that. I’ll be testing power/feedrate settings with my test graphic since that is what my project is.

I finally got some variation. I went with large steps, 20 - 80% power and 1500 - 6000 mm/m. I set the fire button to .05% and it is still visible (I’ll probably disable it during framing).

The following is a text file of the console at startup:

console-start.txt (490 Bytes)

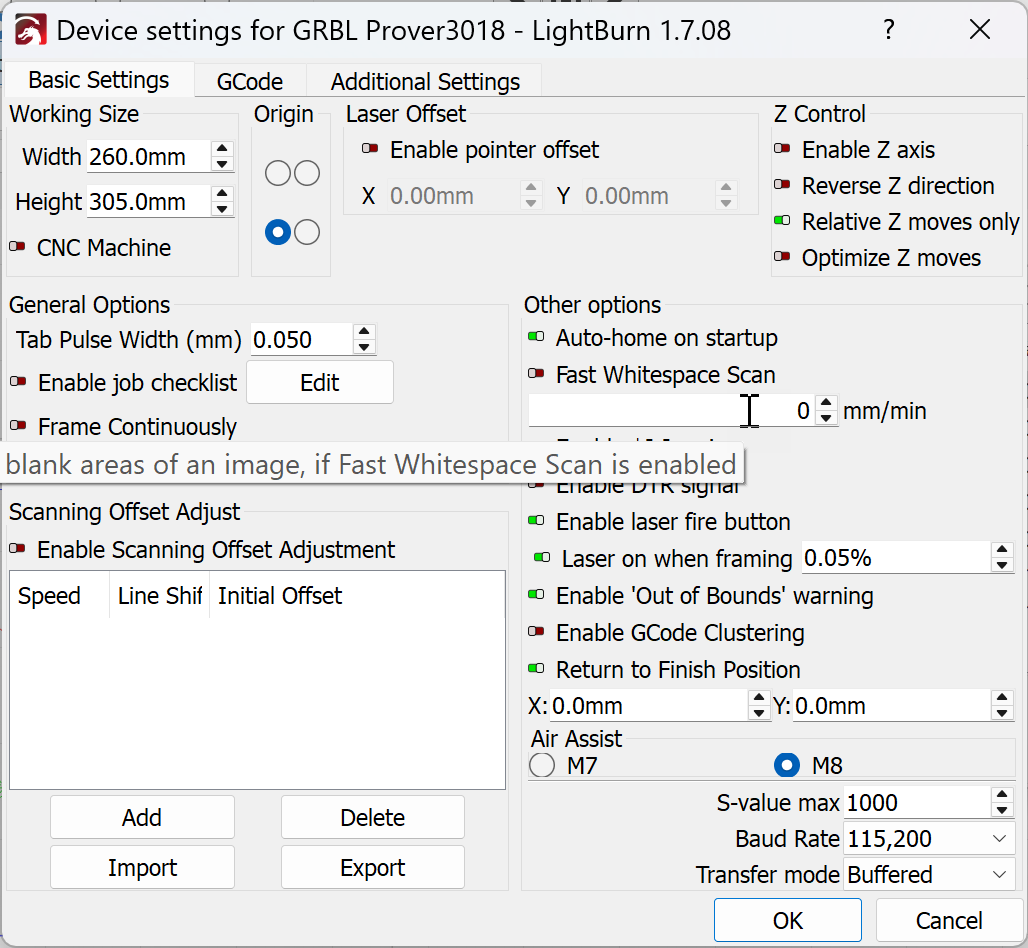

Device Settings:

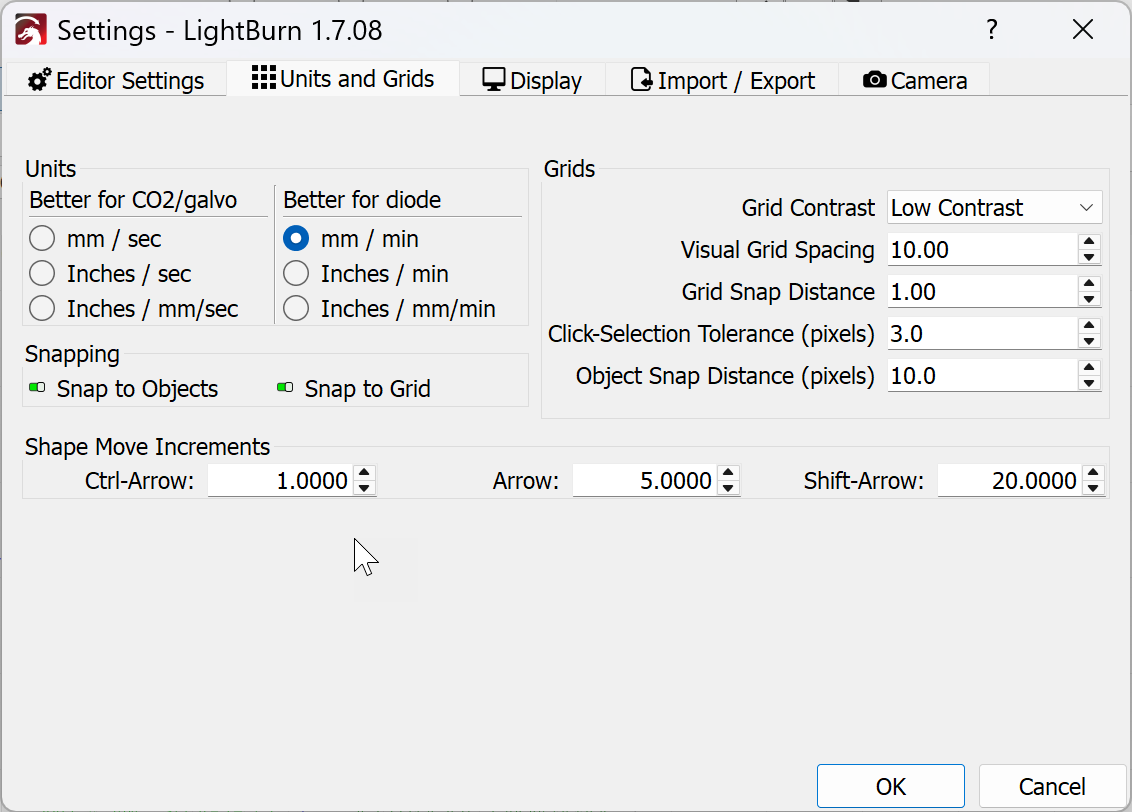

Settings-Units:

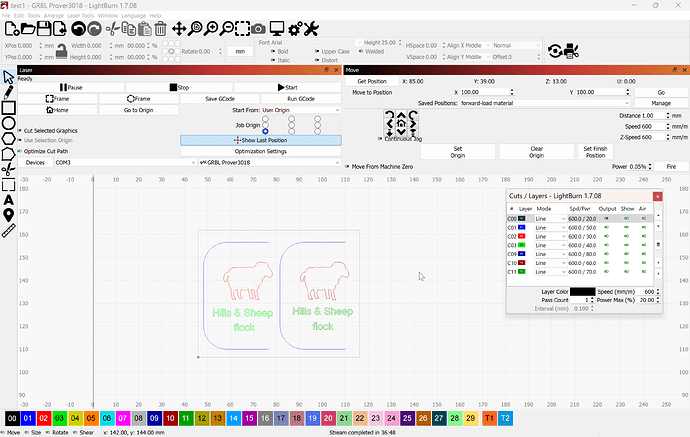

Lightburn screenshot of a test graphic I’m using:

Let me know if more info it needed.

I looked at your console output and several of your settings look wrong to me. Your steps per mm is 800, typically I see values of 80 or 100, your max speed is set to 2,000 mm/min, your acceleration is set to 10, mine is 1,000, and your bed size doesn’t match what you have set in Lightburn. If this is a CNC with a laser attachment, I believe some of the values will be different than my diode, but I think several of your settings are wrong.

If you draw a 100mm square what size square is output?

Thanks for the information.

My machine is the 3018 PROVer but I had installed an expansion kit that changed the work envelope to 300 x 400 mm, I have limit switches so I tested the exact work envelope dimensions using the display from one of the controllers I’ve used, the dimensions are 263 x 307 mm which I rounded down to 260 x 305. I think the console parameters came from a generic GRBL file; I think I got it during my Lightburn installation years ago and I don’t recall seeing a selection for my machine.

I have been using the machine to engrave line art which it does pretty well. I wanted to make a power/speed test to determine optimal settings for line art and I also want to find optimal settings for fill (for a future project).

After my initial tests here, I suspected my machine settings aren’t correct for my machine. When the machine was new I had made some tests comparing physical measurements with the display but I think I did that with the spindle configuration. I’ll do the 100 mm square soon but I’m wondering how to I might determine other console parameters for my machine.

That’s because his machine is a CNC machine. Those values are ok. Though, a CNC, especially the 3018 are not made for speed (as normal for a CNC), so you can’t really go beyond 2000-3000 mm/min realistically.

Yeah, I wasn’t sure about that. I have not dealt with a CNC setup.

I ran another line test. I set 20-100% power and 400-2800 mm/m. I noticed the first 2 columns show different densities than the first test picture with similar settings. Movement distance is accurate.

The 3018 is a hobby machine and it appears to have a limited range of adjustment. But it can accomplish what I need it to do with the laser and spindle configurations. It is a good learning machine (I bought a Onefinity CNC router machine due to experience with my 3018). I’ve been trying to determine the range of adjustment for the 3018.

It sounds like you’re starting to understand your machine.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.