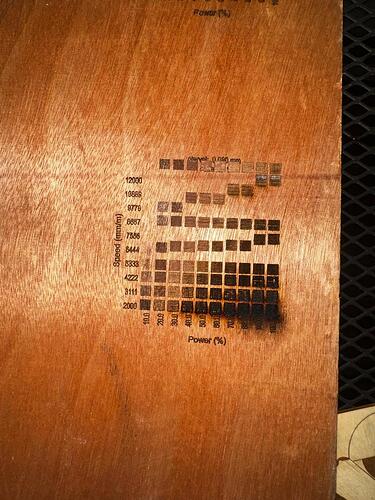

Hi, I have problems running the test material correctly, it starts well but usually about halfway through it fails. Do you know if it is a machine error or a software configuration error?

What settings are you basing this on?

I looked through the Sculpfun site and the fastest they advised for different materials is 2000mm/m… You are starting there…

The control board should limit this, but it seems a bit fast from what I can tell.

Make sure you’re not asking for more than it can do…

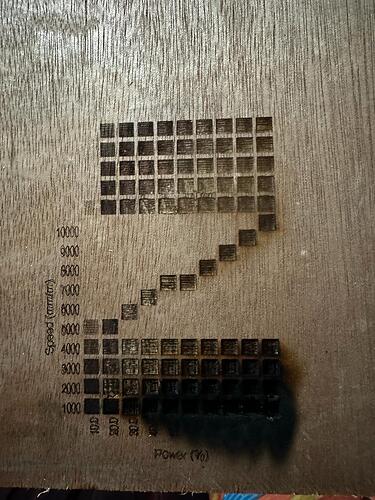

In any case, it shouldn’t be doing this. It isn’t moving to the correct location when it moves to the next box.

Back down the speed and see if you see a change, unless you know it will go 12,000mm/m…

![]()

… and when you have seen that your low speeds can’t handle your Max Power, I think it should change a little too.

Make a rough starter test with 4-5 settings at the “secure” end of the scale and work you up.

Apart from the things already mentioned, you should check the mechanics of your laser. Go through the steps mentioned here, your y-axis is acting weird. Guide to mechanical adjustments and maintenance – Diode Laser Wiki

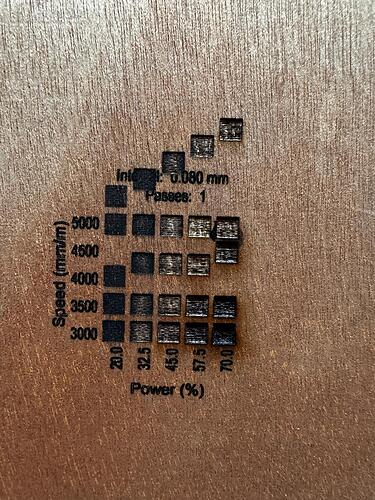

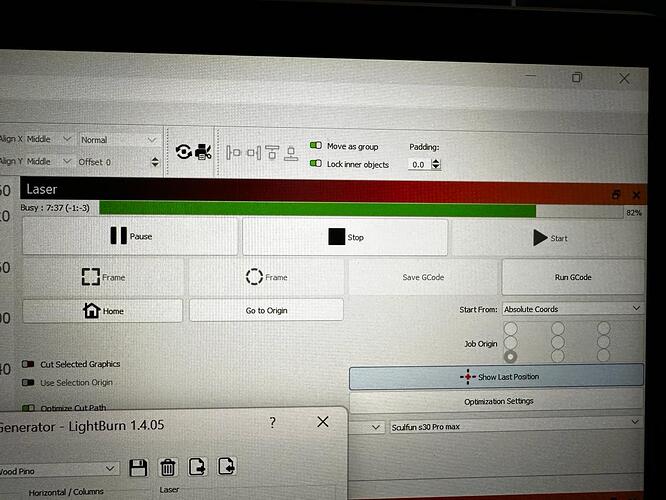

Hi, I did several tests, and still fail.

Things that I have done:

Calibration of the axes.

Cleaning of the lens.

Belt tension and positioning.

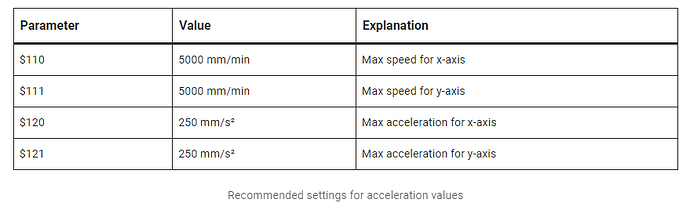

Adjustment of Firmware parameters:

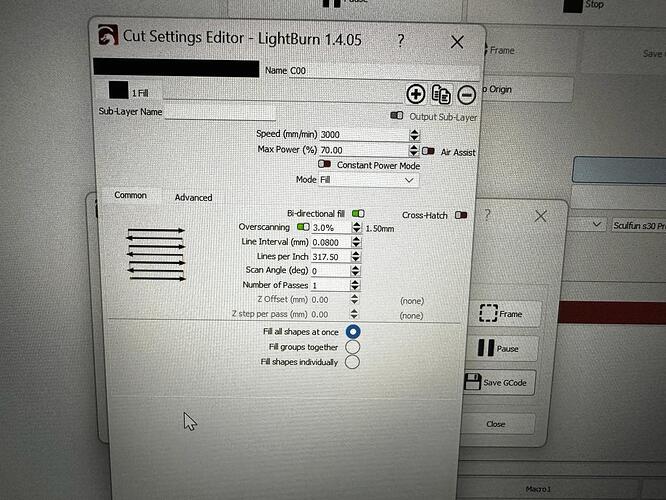

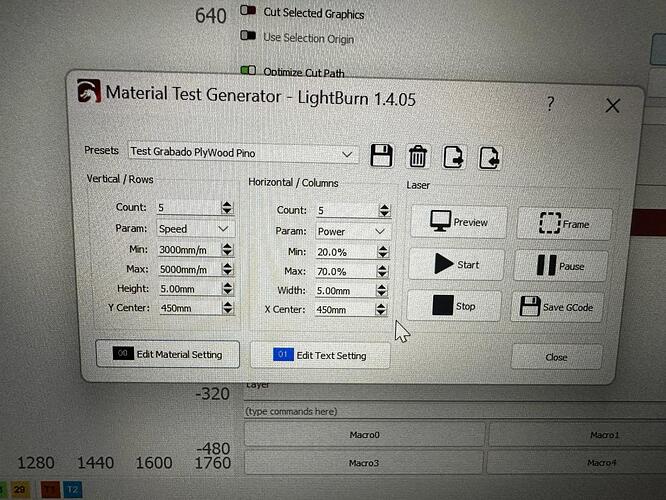

I reduced the parameters for the Material test but it’s not working:

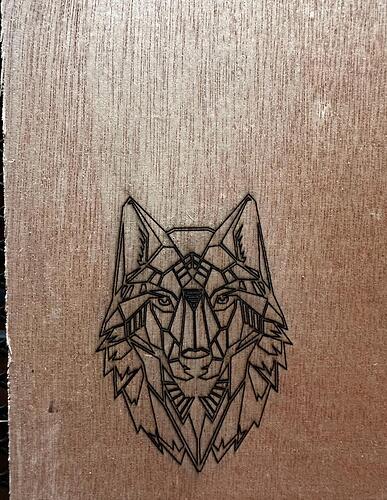

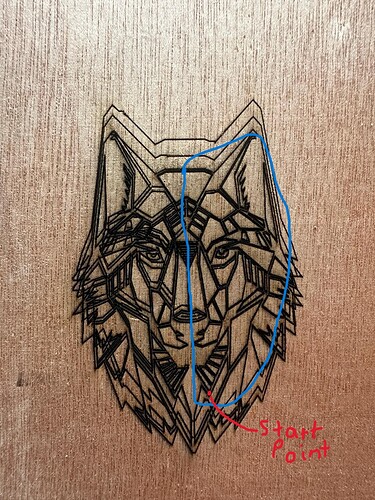

Another issue is that it does not always follow the same coordinates, in the first image the engraving of the wolf ends well with 2000mm and 25% power, 2 passes, and in the second image I changed the parameters to 1000mm and 50% and it started well on the right side but after that, it loses the pattern.

Also, I saw that the countdown is not precise, is this normal? The image has 1.3 min of negative time.

There are 2 possibilities for it, either it loses signal data or it is a mechanical problem. I clearly suspect the mechanical.

It doesn’t just “jump” somewhere else and continue, …loose belt, pulley, lost/loose pinion screw…?

Since the basic geometry is pretty good, I’d guess it’s losing steps due to either high acceleration or some localized mechanical binding.

Try sliding the axes from end to end somewhat slowly while feeling for any change in resistance, jerkiness, grit, etc. Anything other than smooth and consistent.

Much more important is to check the grub screws at the pulleys and motors. Sometimes those get loose and if the motors switch from one direction to the other, the belt is not moved.

Additionally, do the tilt test to see if everything is running smoothly. The wheels are more important here than the belts.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.