Hi,

I’m troubleshooting my setup. It’s a NEJE Master 2 GRBL laser cutter. First, it worked ok, even though I had some sort of a grid lasered to the object. The grid is set 90° to the laser line and looks as if it’s the laser gets turned on and off during filling out a solid black background. But it was ok, the result looked good enough for me.

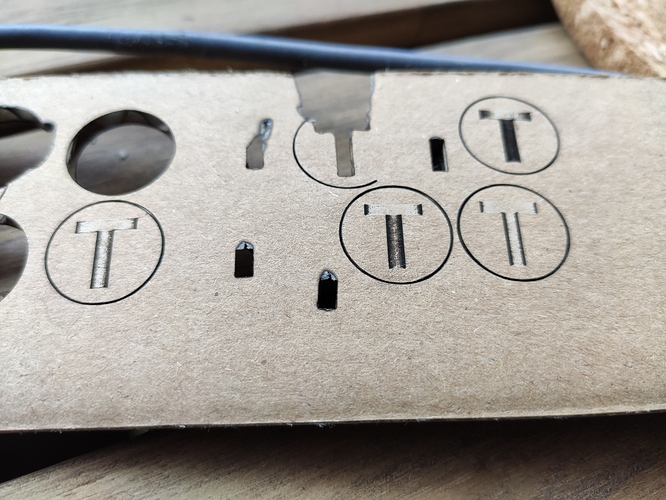

Now, since I moved the laser to the outside I tried to set up an OctaPrint Server on a PI to send g-code to it. Somehow it sadly did not work out. When I tried to laser something with the LightBurn software the next time I had to realize that the Laser now is super strong and just burns trow my material, even though I did not change anything. More power, why not. But now the real problem is when I reduce the power, the only thing getting black is where the laser change direction, but in between its withe, even though it should be solid. In the picture, you can see a test stripe with different settings.

I did reflash the firmware of the laser, but it did not change anithing. Any help welcome! Thanks