Sometimes I lowered the Z, but it would work without it too.

Depth of focus is a “waist” because the cone of energy coming down doesn’t actually come to a point, there’s a small region of constant nonzero diameter. The depth of focus seems to be about 0.5mm tall for the 110x110 lens, the beam is basically the same dia as long as you’re in that small range.

When focusing, I found the “big spark” point, then wobbled the z handle to find the Z range where it basically gives the same spark, then moved to the lowest point before the spark weakened. That would put the blade top at the top of the DoF.

The first phase rastered it out. I was actively trying to avoid having the raster align with the right angles of the design, so I started at 3 deg and incremented at like 48.371deg 50 passes so it never really aligned with the design.

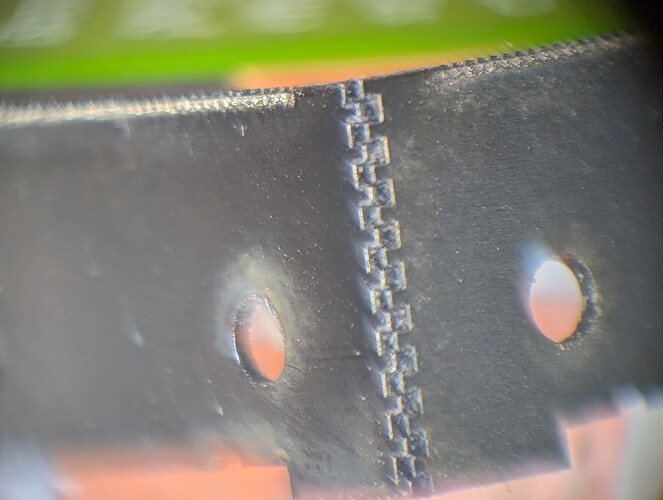

Initially, the cut profile of the teeth was somewhat trapezoidal from the side, narrow face was the one facing the lens. The gap between teeth was narrower on the bottom.

I wasn’t actually sure which direction the trapezoid would face. If the beam diverges slightly but still cut, they could face the other way.

The blade was being held horizontally between two rectangular blocks so it had air space underneath it. Ceramic tile below as spoil, it was about 3/4" below the blade so the beam was too out of focus to cut the ceramic. The air gap gave room for the sparks to fly out freely.

I used an adjustable CPAP blower on a rigid arm to cool it and direct the dust away. It had to be turned down a lot, those things can produce a LOT of high speed airflow, and some static pressure increase too. It wasn’t throwing “sparks” like a grinder, it was a little fine brush of orange past the green flash.

In later revisions, like the box joint, after rastering I just had it follow the line. No wobble. Gave it only a tiny kerf. I just let it run fast on Continuous until I stopped seeing the brush of sparks coming out from underneath. This removed the trapezoid efficiently and made teeth with much closer to 90 deg. Took a couple of minutes.

I also left 2 really narrow tabs on the base. In a third step, I rastered through them until the part just fell out on its own. That part took under 1 min so I just watched it and shut it off manually when it fell. It had enough room to fall that it took itself out of the effective DoF anyways, the beam hitting it after falling couldn’t mark it anyhow.

Kind of amazing, I didn’t clamp that blade. Just held by one rectangular piece of aluminum on top of the other. During the first attempt, it appears the CPAP flow rotated it a bit.

I’m thinking about maybe making tiny tempered steel “watch gears”. Like maybe I could make a flat gear box sandwiched between two 0.5mm faces with retaining pins. Rack and pinions should be possible. Could make wings spring out when you roll a wheel or push a rack-button in. I’ve no idea WHY… just a rough idea of a way to that could make something neat!