The sixth Release Candidate of our new software for CNC users — MillMage — is available for download now!

Continuing the development of MillMage, this release candidate update includes many bug fixes and tweaks.

MillMage-v0.8.00-RC-6 - Change Log

Changes Since MillMage-v0.8.00-RC-5

Bug Fixes

- Fail gracefully on DXF SPLINE objects with fit points (#1149)

- Fixing logic for the tool length probe warning dialog to appear. (#1092)

- Hiding unused values in probe settings, adding missing labels & tooltips in the probe wizard.

- SVG ‘s’ command didn’t work for sequences of points (#1160)

- Some probe values were not being saved to the config

- Fixed bug causing bottom of main window to appear off screen on load.

- Fixed issue with Operations Library not staying within saved dock location / creating a third dock row.

- Fixed incorrect maximum size limit on MacOS toolbar buttons.

- Fixed issue with toolbar icons having edges cut off.

- Fixed issue that could cause main window to load on incorrect screen, sometimes many times larger than the screen.

- Prevent top level menu keys from conflicting with hotkeys.

- Fix to User cancelling GCode generation not actually cancelling.

- Fixed crash on convert shape to bitmap if it was unassigned to an operation, show error message and abort instead.

- Fixed crash on convert shape to bitmap if it was unassigned to an operation, show error message and abort instead. custom error message for LB vs MM

- Ramp angle wasn’t saved/restored, is now also part of tool definition (#1162)

- DEV-1881 Font skips around and reverts on Mac (#1147)

- Qt6 set a 256mb max image size. No thank you. (#1181)

- When pasting a copy of a PathShape, do not create Tabs unless the source cut had Tabs enabled.

- MillMage wasn’t framing relative to workpiece origin (#1183)

- Fixing the framing including shapes without operations, or with operation output disabled.

- Fixed issue causing docks to consume entire window if operating system display scale is changed.

- DEV-1445 Ellipse tool ovals are not exporting properly to DXF (#1178)

- Stop button didn’t properly reset spindle/laser state to off. (#1174)

- Updating the logic & text of the device size mismatch warning. (#1193)

- Removing unwanted conversions for velocities. (#1173)

- Extraneous Velocity Field Conversion, Revenge of Same (#1197)

Existing Feature Updates

- Give stacked buttons a bit of forced extra width to allow side clicking (#1151)

- Show a message if the user tries to calibrate axis while rotary mode is on (gantry)

- Icons for Material Library functions (#1186)

New Features

- DEV-78 Add font management dialog (#1007)

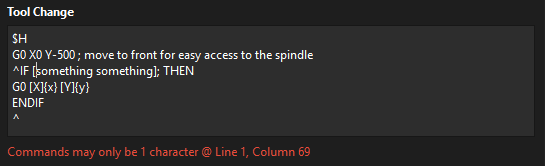

- Custom gcode can now have escaped text sequences.

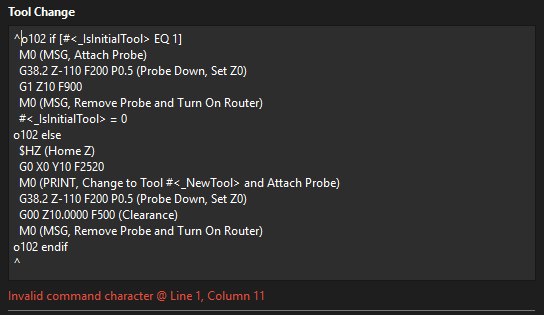

- Make G20/G21 modals editable gcode blocks for custom gcode.

- Remove mm/s as a device setting option.

- Added Drag & Drop to move tools between categories in Tool Library.

- Allow the user to save the position as a machine or workpiece coordinate

Miscellaneous

- Allow user configuration of Z lift offset for TLO probe routine (#1161)

- Remove ability to set Z=0 position

User Interface Updates

- Selected shape / item dash length now scaled for screen dpi.

- Better message for PDF Import Error to suggest converting to image before import.

- Improvement to probe wizard to deal with zero Tool Diameter better.