Hey, thanks for your interest… I took a mental shortcut; it’ll kill me someday… CAD, CAM “sender” in one application is perfectly fine, but not on the principle of having everything on one panel. In Piko, you go to the CAM, and you only have the CAM… you program, set the motion trajectory, click the build/generate button, close the window, and you only see the machine control panel, with the G-code..

I think that nothing else should clutter the screen.

Just look at other machines, serious ones, Mazatrol or Sinumerik controls… each panel has nothing but speed and feed controls, some mist, parking positions, some micro-settings, but nothing like Lightburn. Putting everything on one screen makes no sense ( of course in my opinion) … I am a happy Lightburn user (if it also shows the position in real time and allows to connect grblhal via ethernet (websocket?), then I don’t need anything more. you make a great great job.. I wish you all the best and patience in developing the product, keep doing what you are doing…

to see how software work, you do not need controler.. there are two options. first use it “as is” but with some limitations, or buy a key, and have fully functional sw, of course without posibility to move any machine, as you said, dedicated controller ( full stable, not hainging even once from 2020) is needed

for me, there is no problem to show you how it work by anydesk.. i can install ipcam so you can see in realtim to moves or etc.

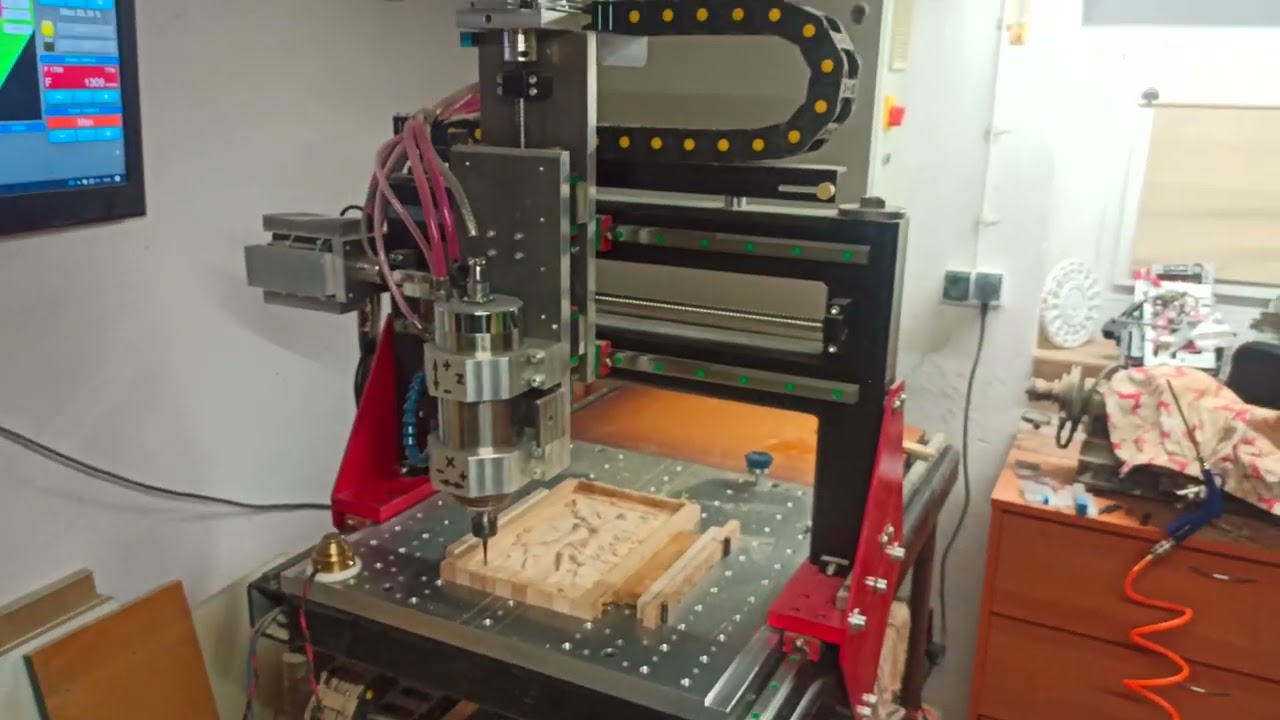

As for my machine, thanks for the kind words… two years of building, the frame is welded, annealed, and milled so that the linear guides are straight on the surface… designed for wood, and in stainless steel it also copes with gentle treatment.