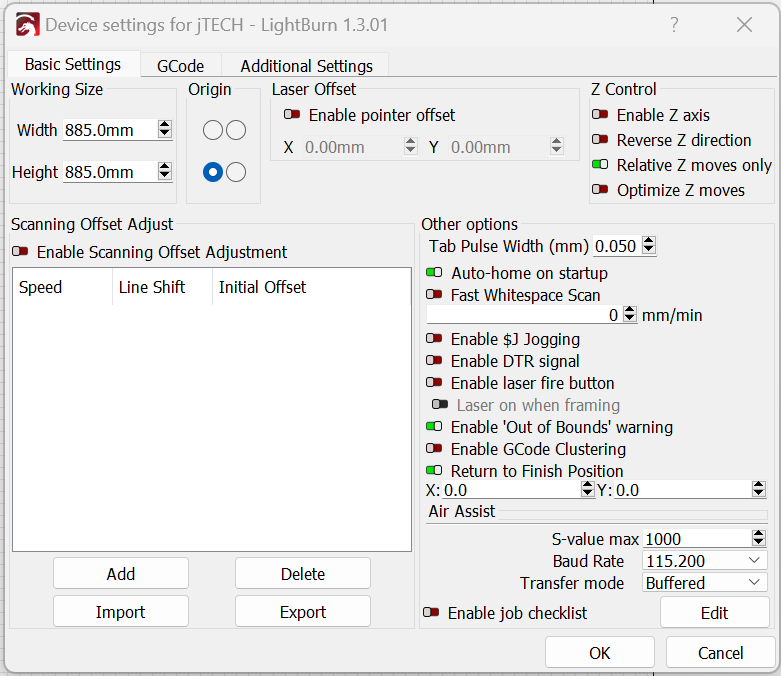

I am having issues with my machine not jogging to the correct position when I use LightBurn with my Mega V. It homes correctly front left ( looking at the machine). When I try to “set laser position on the program after homing it crashes to the opposite corner. I set up the machine as 885mmx885mm (just under the 35"x35” of the work area), set it up as GRBL, and origin bottom left on the “Device settings for GRBL”. I am using LightBurn 1.3.01. The machine jogs correctly on Universal G-Code Sender. How do I fix this problem so I can position the laser head at the desired position?

Thank you,

Jeff