How do I fix that? Whenever I try to adjust mirror 3…I go chasing my tail. Basically, it gets worse…I get frustrated and aggervated…and after a lot of bad words…I finallyget it to what I have now…lol.

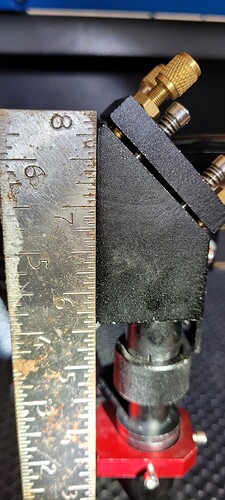

I think first you should take a small square or something and verify that your nozzle is perpendicular to the table. If the nozzle isn’t square in both planes then all else is pointless.

It is perpendicular.

So if its perpendicular …why is beam hitting the side of nozzle on scrap board…but the tape is fine and somewhat centered?

I believe it’s you z alignment is to blame. That beam needs to go down the center of the tube. It has to be perpendicular to the table. In the photo, there is a ‘dot’ above and to the right of the half moon on each pulse.

Can’t see that well, but it doesn’t look square in the photo. What are you ‘squaring’ against?

Are you following anyone steps or video on alignment mirror alignment? Stick with the one you choose don’t try and intermix them until you have a good understanding of how it works.

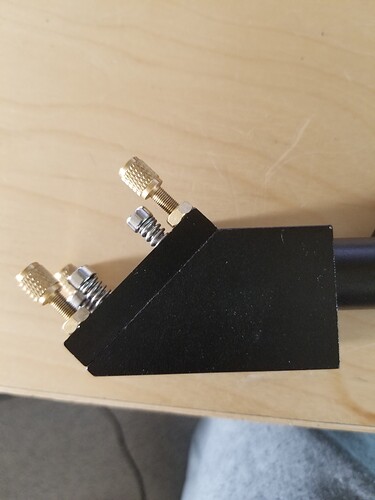

I don’t know how many hours (days?) fiddling with this on my machine. When you’ve done it 1,000 times, it’s a cake walk according to those that lived through it ![]() After less than a month with my machine, I pitched out the factory head and replaced it with one that I can adjust both Y and Z axes.

After less than a month with my machine, I pitched out the factory head and replaced it with one that I can adjust both Y and Z axes.

Need to make a run, so don’t have time to post as thorough idea, but here is my original head. Looking down the beam input the center of the mirror is high. You can see the reflection of the top and bottom of the tube, so I’m pretty straight down it.

Draw a line down the center of the tube and see where it hits M3, not in the center of the axis.

With the mirror and ring removed, does it look centered?

Take the time to really think about it, you’ll nail it… ![]()

OK, perpendicular is good.

I like to take a small piece of clay and put it on the table and run the nozzle down until it puts an imprint in the clay and you can clearly see where the inside edge of the nozzle is. Give it a quick zap and see where the dot is relative to the inside edge of the nozzle.

Photo below is an example of “not nearly right yet”. If it was off a little farther off in that direction the beam would hit the inside edge of the nozzle and reflect off in a crescent shape similar to what you are seeing.

Note that in many cases (including my machine) the beam actually needs to hit the 3rd mirror a couple mm above the center of the entrance hole in order to come out the center of the nozzle.

I think that’s one of the issues. Mine was below center to come out the center of the lens tube. Don’t know if you saw my photos of the tube…

I ordered some 321 blocks…figured that be best way to make sure bed is level.

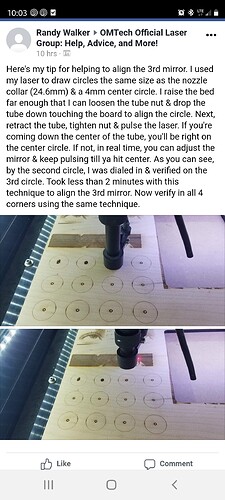

I watch a lot of YouTube and like Cam Edmonds videos.

Not sure I follow, but if it works, stick with it…  Good luck

Good luck

321 blocks are precision ground blocks that are 3 inches by 2 inches by 1 inch.

Machinist use them all the time. I figured this would be an easy way to make sure my bed is level by checking all 4 corners with the 321 blocks.

Looked them up. Nice to have level, but what you want is to get the beam in the same point it enters the head at at points of the work area. Most just chose the extreme longest and shortest distances.

Even with that, you need the beam to go down the center of the lens tube so it strikes the center of the lens. When it’s off center the cut has a slope to it, even if all else is correct.

I use a machinist square against my table to check for perpendicular. Move the head around and check height. I have an dial indicator but it really seems too sensitive. Check it in the middle area, that’s where mine varies the most. Right where I use it the most

I guess I don’t see how that’s going to help with alignment. I’m probably going the other direction thought wise anyway…

Good luck… Take care.

I check mine at the entry of the lens tube. I can move it up and down to check it at both ends of the lens tube travel. Your head may not allow that kind of alignment. Use whatever procedures works for you. You will refine them as you move forward. There is literally a ton of videos out there on this.

Good luck, take care

Don’t know what I did…other than move a bunch of screws…but it’s a whole lot better. Getting a nice small crisp dot.

All 4 corners match up pretty good too.

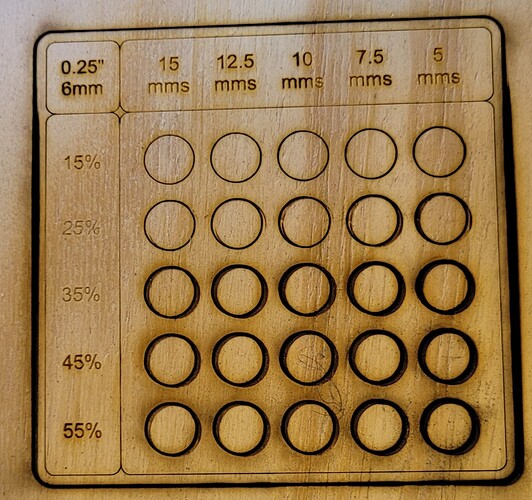

Did a ramp test…best I could.

Video I watched (bearded builds on youtube) had the nozzle touching the wood at the start. He then made a 12 inch line at 50speed/20 power. I had to go back and change my settings cause mine was doing it super fast with those settings…but alas…I was in inches…not mm!

My bed won’t go any higher and it has quite a bit of space between nozzle and board.

I still did the test…and smallest point on my line is the same as the acrylic piece that came from omtech for my focal length.

Unless you changed lens, it has the same focal length. The only other options are a different placement in the lens tube, different nozzle. It’s where you measure from…

So sounds like you’re up and running.

Take care

Nice job 🤸

All you really need is it to start at a short focus (fat line), gets thin, then fat again. That covers the whole focal range you’re interested in.

I sometimes start mine close. Based on a couple of things, like convenience, less turns on the Z knob…lol Sometimes what’s more important is ramp angle, depending on how close you want to measure. A long slightly sloping ramp in the critical focus area can be informative.

You’ll know when you fit a lens you’ve used about where it needs to be.

However, you will develop your own technique that fits your needs. ![]()

Trying to do the .25/6mm file card.

Its not burning all the way thru…focus length was checked prior to running the file.

Help

Somethings not right. That double line stuff is not normal. Are you sure your beam isn’t clipping the inside of the nozzle or something?.

last i checked it…it wasnt…but who knows…I’ll be the first to admit i don’t know what I’m doing…lol

Mirror curved side up? Mirror seated flat and square to the tube? Tube in head is square to the head? You can check for square to the straight parts of the head, but the tube is still crooked.