Happy New Year!

I have a 130w Co2 laser that lives in my work shop, where I work mostly with wood, using saws and a CNC Router.

Due to the laser’s size, my shop is the only place I can keep it, so I am CONSTANTLY struggling to keep dust at a minimum.

I have upgraded the fume extraction and air assist so smoke residue on the mirrors isn’t a big issue, but as mentioned the dust is.

I keep it covered with a large tarp when I am not using it, but dust still finds it’s way inside the cabinet, most specifically on the mirrors so I am constantly cleaning them. And because of the constant cleaning they have become discolored with the laser losing power so I have new ones on order.

Now, with that…

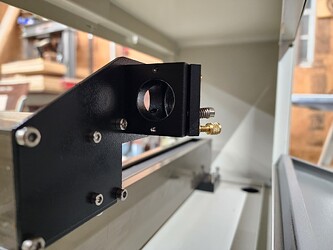

I am pretty handy with a 3D printer and Fusion 360 and I had an idea of printing some covers to fit into the openings of the mirror mounts, which as of right now are about as large as the mirrors are, approximately 25mm in diameter.

The covers would have a large enough hole in the center to allow ample room for the laser beam to pass through to and from the mirror, but would reduce the size of the openings in the mount on each side to help reduce the opportunity for dust to find it’s way onto the mirror. I know this wouldn’t eliminate the dust, I am just trying to reduce it.

My question to you good folks is:

Is this a dumb idea?

Would this cause problems that I am not considering?

Thanks in advance for any feedback.