2000 or 6000 is fine for now but 2.0 is not the same and you do not want 2.0 mm/s2 for acceleration.

FYI, you will notice if it is accelerating too fast but right now that is not the problem, it’s going way too slow.

The value is 2000 but lightburn show it as 2.000,000

if you go to the terminal and enter $$ it will show you what GRBL has for the setting, no translation for display. I learned the hard way that LightBurn does various validation checking on what’s in the GRBL settings so I go straight to GRBL to make sure nothing is misrepresenting what the settings are.

I used GrblHal which is a 32bit upgrade of standard GRBL and as such also had a number of extra features not part of the 8bit GRBL.

X max rate 20,000.000

acceleration 2,000.000

Y max rate 3,000.000

Y acceleration 500.000

it’s really hard to make out if they are commas or full stops

thousands or fractions

also on your motor drivers, what is the X and Y microstep steps/rev settings ?

a max speed of 333 mm/s seems on the high side for a stock K40 but ok, might be noisy.

50mm/s for the Y max rate seems way to low unless you are only going to be doing engraving.

Engraving typically will scan along the X axis very fast and slowly move the Y but who only does engraving?

You shouldn’t be worrying about microsteps and steps per mm at this point.

You should have first validated your home switches, then the home function so you’ve already adjusted the homing directions right?

After you have that validated, only then do you go and try to use the machine or else you’d be in jeopardy of slamming the head against an end and tearing up a belt.

After the first tests you then do movement distance testing to make sure when the machine is commanded to move 100mm in a direction it moves exactly 100mm. This is when you adjust your steps/mm and concern yourself with microstepping. My K40 has .9 deg / step motors so not sure what yours has. They are not all the same. If you look inside the smoothie configuration file posted you can find my settings.

again, not an issue unless you’re not getting proper motion distances. 16 microstepping is very common but some run 32 if they have fast boards.

Only for recap…

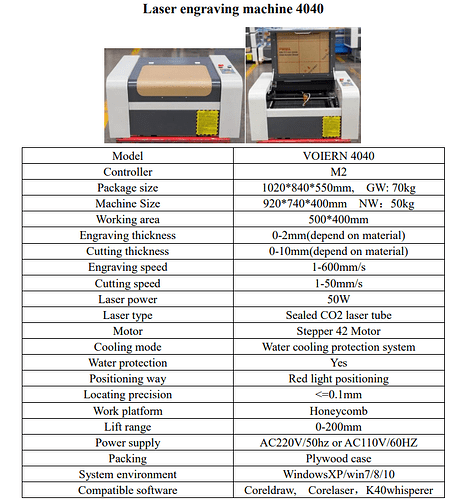

I don’t have a simply k40 but a VOIERN 4040 50w that is more powerfull…

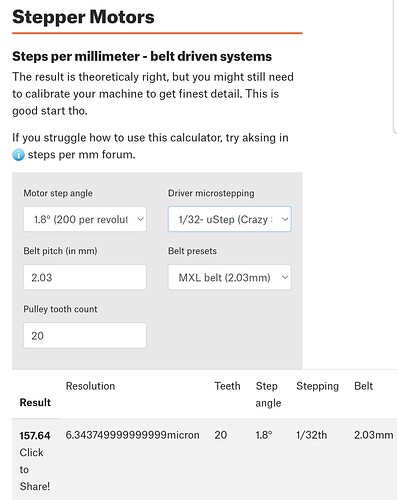

With an online tool I have perfectly set step/mm of my CO2.

My controllers are two A4998 set with G1 G2 G3 up, so I’m reading online this is the configuration of 1/16 microstepping but with the online tool I had to set to 1/32 ![]()

With the stock parameters I was able to make perfect cut / engravig of words or other things, but doing raster images I have seen that the x axes movment was slowly than the expectatices and there is a noise while movment.

So I have started asking on telegram groups and here If anyone can help me… and lots of people told me to increase the X axis velocity and acceleration.

Right now I have a machine that is faster than with the stock parameters but with the same problems doing images.

I don’t want to play with the parameters with the risk to break something beacuase I don’t make images every day but it will be fantastic if there is a solution to make it perfect in all jobs it can do.

ps: sorry for my bad English I’m Italian and I’m trying to write at the top as mine possibilities

you should be saving your configurations and labelling them based on your testing. Not having a backup and restore process is asking for trouble.

Did you know that you can do things like set the $120 setting with a command like this: $120=6000.0

And this means that if you save the settings listed with the $$ command you can copy and paste them back if needed.

I was previously asked for my K40 settings so I figured your machine was like a K40.

If you used the online Motor Steps calculator using 32 microstepping yet your board is setup for 16 microstepping AND you’re measurements of moving 100mm in X and 100mm in Y are exact then something is wrong. You should have measured 200mm if you’d calculated for 32 microsteps but your drivers are set for 16 microsteps.

What do you have set in LightBurn for your max acceleration and speed? Not the GRBL setting but I think there are GCode parameter settings which could be limiting your performance.

Always backup,

first save your current firmware to a file

before burning the new firmware

if you want crash safety, set up hard limits $21=1

steps/rev selected with switches on the driver very much affect smoothness and torque, my motors are running X 6400 & Y 12800 pulses/rev (different gear ratios)

my DLC32 has

travel resolution steps/mm $100 $101 to adjust correct distance travelled.

$110, $111=1,000 mm/min max rate

$120, $121=500 mm/sec2 accel

which is slow and steady, but within my cutting/engraving range for my diode laser.

I’m moving a full sheet of ply with feed rollers, so too much acceleration is a no-no on my machine

I cut 4mm ply @ 300mm/min 100%, 3mm ply @ 500mm/min 80%

engrave @ 1000mm/min < 20% but could engrave faster with the laser up more.

If you can cut faster and if you’re time constrained put your max rate up, but also wear and tear on your machine.

Laser lifetime is defined by power*time.

It’s always nice to have a link, such as your online tool… It’s sometimes tough to find these when you’re not sure of anything else about it…

If this is your machine… it looks very much like a K40…

A few inches wider and deeper, but it looks much like a K40.

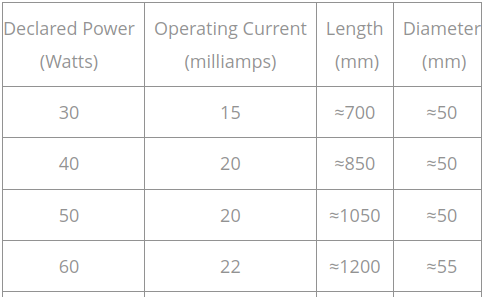

The power of these co2 dc excited lasers is related to the physical size of the tube… a 50W tube is over a 1m in length.

My 50W OMTech cabinet was 1040mm and it’s tube was only 880mm, producing about 40W. You need extra room for the mirror, at minimum, then usually some type of clearance added to that.

The cabinet size of your machine is only 920mm. The best way to guesstimate a power value is to measure the length of your tube…

In all intent it appears to be their version of a K40…

It’s current controls are detailed just like a K40 is wired up…

Looks like a very nice machine, but most of these are advertised. They knowingly and notoriously overrate their performance.

On a standard grbl, you can load modify and save all of your machine settings via the Edit → Machine Settings gui and do away with the cut/past method…

I don’t have my MKS DLC32 up right now…

@DougL I have the one with an include display… Can I ask which firmware version you run and were to obtain it…

I flashed the one the .bin recommended from the vendor and lost the screen… gives me lots of junk on the console.

![]()

Mine runs Smoothieware on an MKS Sbase v1.3 and you already saw my config file. It’s been a long while since I updated the firmware but I did find a Backup dir which had bin and config files labeled 20200501.

20200501-working-config.txt (28.2 KB)

20200501-working-firmware.bin.txt (349.0 KB)

Got’em. I’ll flash them and see what they do…

Do you use an application for loading the firmware? I use some python uploader that has lots of other information on the command line… I don’t know these large controller yet… If they are 10 times as complex as the 328p types… I’m in for a long hall…

Thanks…

![]()

Mine already came with firmware and bootloader flashed so all I had to do was copy the bin file to a uSD formatted to FAT32, at the root level as named firmware.bin and then install in a de-powered board and on power up it will flash some LEDs and when stopped it’s done flashing and is running. But it will also need the config.txt file also in the root directory of the uSD.

You can tell if it flashed correctly if you power down and then check your uSD card for a file named firmware.CUR which is a backup of the previous loaded firmware.

I connected to my K40 and obtained the version info:

Build version: edge-e616a0e, Build date: Jun 18 2018 09:27:48, MCU: LPC1768, System Clock: 100MHz CNC Build 3 axis

I’m pretty sure it means I built it on my laptop since I also found these instructions in a script:

> cd Smoothie

> git pull

> # sets up build env and installs gcc arm

> #./linux-install

> #./BuildShell # this is the build env setup

>

> ./BuildShell

> make clean

> make CNC=1 all

> mv ./LPC1768/main.bin ./LPC1768/firmware-cnc-latest.bin

Hi @jkwilborn

This is the link of the online step/mm calculator that I used in order to perfectly set my machine:

And this is a photo about of my machine:

Yesterday i have wrote directly to the support email of MAKERBASE in order to know in order to know if they can give me more info. about the problem that I have.

I’ll post here their reply about it

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.