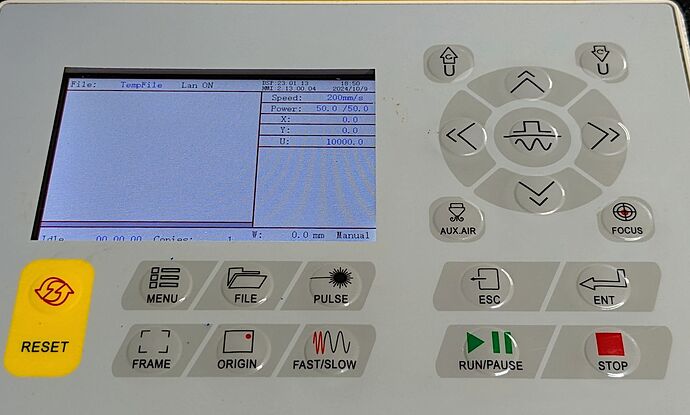

This thing has a Ruida KT322NZ controller.

Everything works for the most part, and this is somewhat of an oddity, which I think might be a bug in lightburn (or rather, a workaround for a different laser not applicable to the onyx R, but which can’t be disabled, as far as i can tell)

In the ‘Move’ window, the reported Z position is actually the U axis position.

- The U axis position shown in the move window is 0.0 (which is fine, there is no U axis in this machine).

- The Z axis position shown in the move window is 10000 (which is wrong, that’s actually the position the controller reports as the U axis.. (ish? see below) )

- X and Y are fine.

When I sniff and decode the serial comms going over usb, when i click ‘get position’ in lightburn, the laser actually reports the correct position for Z, but it seems lightburn chooses to ignore it, and the reported U position is what it’s showing for Z:

Get position request (X)

Get position response (X) = 190.096

Get position request (Y)

Get position response (Y) = 83.702

Get position request (Z)

Get position response (Z) = 9.925

Get position request (U)

Get position response (U) = 9779.889

Oddly enough, the up/down arrow keys in the move window, and the focus button do control Z correctly - so it does the right thing when SETTING the position - but not when reading it back.

It does not however, behave correctly when I enable Z axis control and set a non-zero material thickness in a layer. That just causes the laser to hang.

But when I bang bits into the laser by hand, sure enough I can make it set a position for Z just fine.