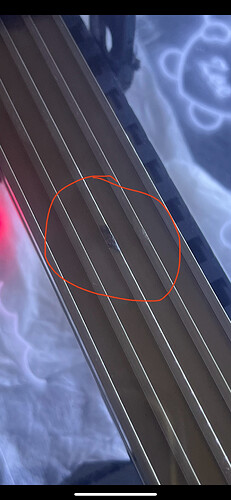

Monport 60w started acting weird mid job. The gantry was only moving back and forth along the x axis a few millimeters (it should have been ~100mm) and was making a loud almost grind like sound. I cancelled the job and attempted to move the laser back and forth along x and it acted as if it was jammed then suddenly broke free. Upon inspection the x rail had severe damage that grinded the top of the rail and there were metal shavings inside the gantry (which I believe came from somewhere else). I cleared the shavings annd checked for obstructions and found nothing. I ran a job with no issues after. I ran one more job and the issue reoccurred on a different spot on the x axis. This time I stopped it before it damaged the top of the rail. However the side of the gantry had more metal shavings. I should also note that the laser moved about 100mm off its set job area as well when the second failure happened. Anyone ever experience this? Monport support is basically nonexistent when they can only email back at 2am.

Well, you’ve eliminated LightBurn, the controller, and all their settings from the fault tree. ![]()

When a stepper motor stalls due to mechanical overload, the rotor loses sync with the controller’s commands and can rotate at unpredictable speeds in either direction: the motor is not at fault.

Unfortunately, expecting any seller / manufacturer to do anything useful during a major warranty claim seems … unwarranted. You should certainly start a claim, but plan on ending with a full-frontal DIY repair job.

With a few exceptions, these machines contain standard parts that are cheap and readily available. After you figure out what you need, you can buy replacements and install them without too much trouble.

At a minimum, you’ll need a whole new new linear slide assembly; don’t try to replace just the carrier or just the rail or just the bearings, because they’re all damaged.

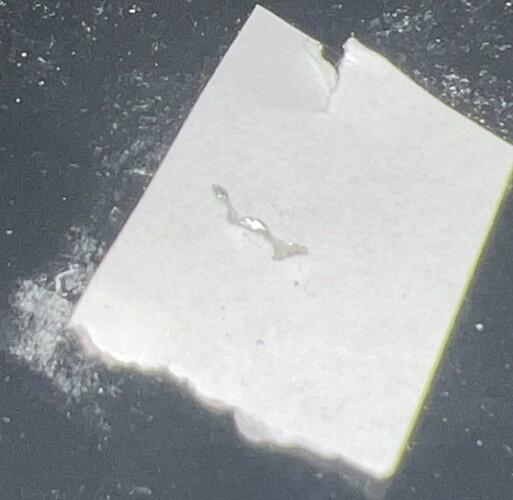

Thanks for the reply. I took apart the entire X assembly and found that the left side roller for the belt had a lot of damage on it (chipping). I cleaned out all the metal shavings and greased everything and gave it another try. This time the outer ring on the roller that keeps the belt in place totally snapped in half. Of course support is no help so now I’m trying to figure out where to get parts. Nothing useful on the website either. Would you know where people usually get parts for these?

That’s unexpected! The idler pulley shouldn’t see enough force from anything to tear it apart like that.

You can find such things on Amazon, although matching the ID / OD / width poses the usual challenge:

https://www.amazon.com/s?k=toothless+pulley

The sizes will be hard metric, so don’t trust any inch measurements you may see. ![]()

More poking around with slightly different keywords will produce an entirely different selection, so expect to devote some time to finding out what’s available.

If that fails, drill down through the layers at Grainger:

There’s nothing wrong with a toothed idler and (IIRC) St. Sadler suggests meshing the teeth may eliminate some mechanical vibrations. Make sure you get a compatible tooth profile, though, perhaps based on any information printed on the back of the belts.

Inspect everything else for damage: feeding metal fragments into ball bearings doesn’t do them the least bit of good. The left-side Y axis linear bearing may have eaten a few fragments, too, so figure out how to get a good look in there, too.

Good hunting … ![]()