Hi folks, i am super new to the lightburn, so please bear with me ![]() I am having a very strange issue.

I am having a very strange issue.

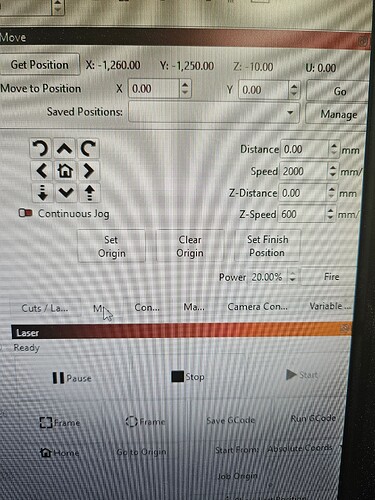

When i start LightBurn it homes the machine - that works perfectly. Homes it in the bottom left corner, as expected. The coordinates at the top of the screen show X -(minus)1200 and Y -(minus) 1200. When i go to use Move button it sends the machine diagonally to X0Y0 position in the top right corner!. Once it is there, it triggers the limit alarm (righfully so) when trying to move up or right, left or bottom does not do anything.

I tried to move laser head through G code and it works properly. It executes Gcode design properly as well.

If i switch Device Settings → CNC Machine-> Yes, then the Move buttons move properly (+10mm, as required), but in reverse direction.

Just to add, my laser is added to QueenBee CNC machine. I use GSender to route with it and that works properly, so it is not a setting in GRBL.

Any ideas?

Examine the G54 parameter for its value. If it is all zeroes, then try this:

G10 L2 P1 X1200 Y1200

This this tells the machine to report the Home position as the Machine 0,0 position.

You can undo it with G10 L2 P1 X0 Y0 if needed.

Something is really wonky here.

Differences between offset and reported position:

X 27

y 127

Z 34

Do this so we can see what might be happening…

- Enter $$ in the Console window.

- Enter $# next

- Enter $I (eye) next.

- Enter ? next.

- Enter $G next.

Copy everything starting with the $$ and below, and paste it in a reply.

In the Machine Settings window, click on Save to File. This is your safety net.

Once we get the original settings documented, I would like to make some changes to the parameters to see if we can get them making sense.

By the way, camera pix of the screen suck because of the interference patterns. Please use the Windows Snippet Tool ( Windows key + Shift + S).

Thank you for your response Mike. What is really confusing is that gSender works perfectly. Most of the lightburn works perfectly as well, except for move buttons. Btw, the steppers sound awful when Move button is pressed and it starts moving diagonally.

This computer has no internet, as it is in the cottage. That is why i had to take screenshots with the phone

Here are the settings

Summary

$0=10

$1=25

$2=0

$3=0

$4=0

$5=0

$6=0

$10=1

$11=0.010

$12=0.002

$13=0

$20=1

$21=0

$22=1

$23=3

$24=100.000

$25=3000.000

$26=250

$27=10.000

$30=1000

$31=0

$32=1

$100=320.000

$101=320.000

$102=800.000

$110=4000.000

$111=4000.000

$112=2000.000

$120=400.000

$121=400.000

$122=200.000

$130=1270.000

$131=1260.000

$132=250.000

ok

$$

$0=10

<Idle|MPos:-1260.000,-1250.000,-10.000|FS:0,0>

ok

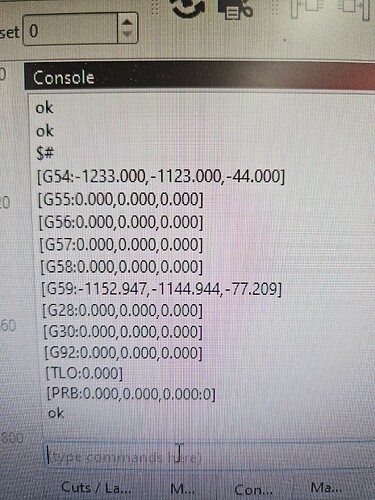

$#

[G54:-1233.000,-1123.000,-44.000]

<Idle|MPos:-1260.000,-1250.000,-10.000|FS:0,0>

ok

$I

[VER:1.1g.20180813.Mega:]

[OPT:VNM+,35,255]

Target buffer size found

ok

?

<Idle|MPos:-1260.000,-1250.000,-10.000|FS:0,0>

ok

$G

[GC:G0 G54 G17 G21 G90 G94 M5 M9 T0 F0 S0]

ok

I am pretty sure gSender, like Candle, is just a CNC code pass-thru program. You build the code outside of it.

Are you saying that you can create a drawing in Lightburn, save the GCode, and send it to the laser, and it works as expected?

Yes, not only that, if i run the design from lightburn, it burns perfectly.

Hold please, I need to process everything in this posting… ![]()

No worries. I am going home today for couple of weeks. Maybe when i am back i will try other lightburn alternatives.

Ok, Message me when you return.

I am firmly convinced your coordinate system needs to be redone. It is just a coincidence that it works (mostly) with the current settings. However as you know, something is not right because of the “Move button it sends the machine diagonally to X0Y0 position in the top right corner” statement you made.

You have two choices:

- Use it as-is and live with any quirks/aggravations it has.

- Reset all the coordinates to “neutral” and set up everything including Home direction, Jog direction, and Machine work area offset.

#2 Does not necessarily mean the factory settings. Sometimes get it out the door is more important than get it right.

On my CNC Mill/Laser, $10=0 seemed to work best for reporting position.

Enjoy your 2 weeks off!

Thank you Mike. Appreciate all your time and help!

Hi

Did you manage to fix this?

I’m having the same issue but I don’t see a resolution on here

Thanks

Aaron

So just so I understand, where is the machine when GRBL reports MPOS X0 Y0? Front left or top right?

The machine homes bottom left but grbl reports 0,0 top right

Ok, that’s because of your G54 offset.

If you don’t mind resetting G54, can you please try:

G10 L10 P1 X0 Y0 Z-44

(assuming the Z value makes sense for your focus, otherwise set it to 0 as well).

Then in the device settings, set origin front left, disable the CNC Machine toggle (it’s meant for those homing in the back right) and see if it jogs better for you.

You can backup the values of your G54 offset by reading them off and writing them down / saving them in a text file using $#

The command you gave did not work don’t think it should be l10?

I have already set the g54 offset to be zero and having spent best part of a day on this km getting ready to punt on this software

Oh if you already have G54 set to 0, then just skip that step.

I guess G10 L10 may not work on older GRBL… It may be a different parameter. But if you’ve set it to be X0 Y0 then you should be ok if you set the origin to bottom left and disable CNC Machine.

If it still doesn’t work, you can try turning on Machine Coordinates, and that will work in G53 mode instead of G54.

Is there any documentation on this as it’s getting really frustrating now

My understanding is that off sets defined when doing a $# are offsets from the machine zero?

So I’m my instance I get a g28 in the list of offsets that is g28:-417.000,-427.000,-3.000

This is the offset from the top right corner to the home switches with a 3mm offset from the switches.

If I want my g54 0,0 to be the same as the g28 home position then the offset in the table for this should read the same.

I am also having issues with direction of travel and diagonal movement which I assume is the incorrect working positions?

I can fully empathize with the frustration. The headaches involved in making a system that works for both lasers and CNC machines has been grueling.

So if I understand you correctly, G28 is somewhere in the middle of your machine’s workspace, and that has become the reference point that LightBurn uses to move from?

To change your G28 reference point, you call simply use the position where your machine is after the home position (if need be send a G53 G0 X1 Y1 in the console if it somehow moved after the homing cycle finished), and use the G28.1 command.

I was just re reading the Grbl documentation here on which gcode standard they try to follow, and they themselves refer to the LinuxCNC documentation.

You can find the LinuxCNC gcode definitions here: LinuxCNC "G-code" Quick Reference

Essentially, if your CNC homes to front left, then you want to reset all your workpiece coordinates, and sat up the lightburn device origin to bottom left, disable CNC machine and leave machine coordinates switched off.

The CNC machine toggle is for users with CNC machines homing to the back right, to tell lightburn to use negative coordinates instead of positive coordinates.

Most purpose built laser machines with a gcode controller will have 0,0 wherever the machine homes, and operate exclusively in positive coordinates. So if the machine homes back left, that will be its 0,0, but the front right corner will be its xmax,ymax position. It seems odd coming from the CNC world, and it’s even weirder trying to write the coffee that has to handle all those weird cases.

This is the best I can do tonight, but to help you more if this isn’t enough to get you going, please email support@lightburnsoftware.com, or staff will have more time (we have staff in multiple time zones) to work with you on setting up your machine.

The frustration is this has been working fine for over a year - then I went on holiday for a week. On return I am living a nightmare without a single setting change !

The g28 reference point is provided from the home switches at the bottom left of the table. I assume that the co ordinates for this position are derived from the max x and y settings provided in the setup. I have looked at the Linuxcnc docs and they are not the best to be fair. I have managed to get the machine working fine and then i re-home the machine and it all goes wrong again. Even the axes don’t move in the correct orientation. I can use the machine fine using open builds for motion control and it works as it should

I must say that the implementation of the coordinate system in this application is not easy to work with. If there was at least some reset functionality or documentation that could get you out of this situation then that would be a good starting point. I’ve spent a day and a half now trying to get this sorted and still nothing