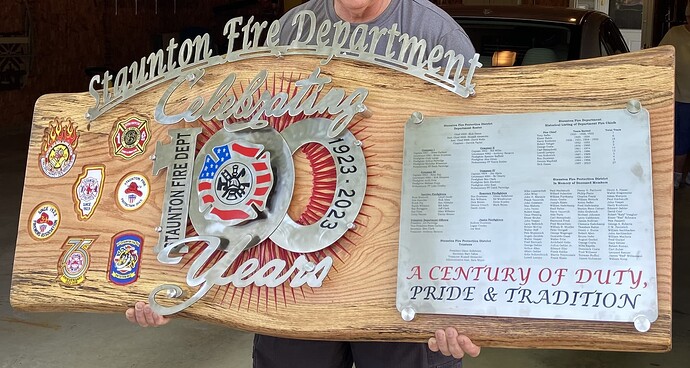

Here’s a multi-process project where LB was used for all the graphic layout and redraw in prep for CNC toolpath process and cutting. LB was also used for all laser process toolpath, cutting, and SS etching. The centerpiece “Celebrating 100 Years” design was done by a fellow FF, I just traced/redrew as needed for CNC process. SheetCAM was used for wood routing toolpaths on the red oak live edge slab, FF cloth patches are inset into pockets and red starburst is vcarved, then painted. SC also used for 12ga. 304 stainless steel plasma cuts. LB was used again for laser cuts to make vinyl decals on SS, and ‘etching’/printing of FF name lists on the SS panel. This was built with a single CNC having swap-able cutting heads, a custom MillRight CNC MegaV XL. Overall dimension of plaque is 57"Wx26"H.

The project was a lot of fun, but not without stress at times since several process steps were first time with software and material. I had help from my buddy Blaise.

Items of note for those interested in the process details:

- SS moly printing seemed to work best on fine polished finish, where the sanding is one direction leaving fine parallel sanding tracks. 400 grit wet/dry paper used to finish sand to near mirror finish. CRC 3084 Dry Moly Lube used for print medium because I had it, but an Enduramark product has been recommended and should offer easier cleanup on such a large area. 600mm/min, 100% pwr on a 15W dual diode laser, 0.085mm interval (300 LPI), 1 pass, finest focus. Even though pwr was 100%, not usually recommended for long jobs like this (5+ hours), the laser body temp, according to the onboard monitor, did not exceed 33 deg C because of the large whitespace gaps in the raster lines.

- SS cleanup and finish on other pieces was accomplished with combination of 60 grit flapper disk and semi-solid poly fine grit abrasion disk, making a swirl pattern high sheen finish. This disperses reflected light in random directions leaving changing and interesting patterns when viewing.

- the SS digits (100) and maltese cross are individually cut and then one welded unit before mounting.

- the SS mounting standoffs found on amazon, 3 heights and dia.

Congrats to my FF brothers on the Staunton Fire Dept for “A Century of Duty, Pride, and Tradition” protecting the citizens and property of Staunton Fire District in south central Illinois !

Cheers,

Lou