Hi all,

I thought I’d share the enclosure I made for my laser, in case some of you find it useful. The first big difficulty I placed on myself was that it could only be done with wood I collected from the street(I’m in Amsterdam, it’s crazy how much stuff people throw away here!). As always, I didn’t plan much, but added and improved as I built:)

Front opening for larger pieces, one switch for laser pointer/lights/usb extension cable power/air intake, plus one for laser and one for air assist. Lightburn camera on wooden bracket.

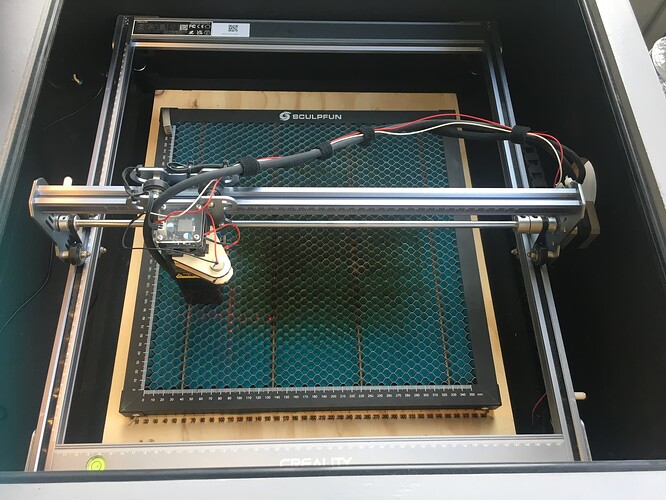

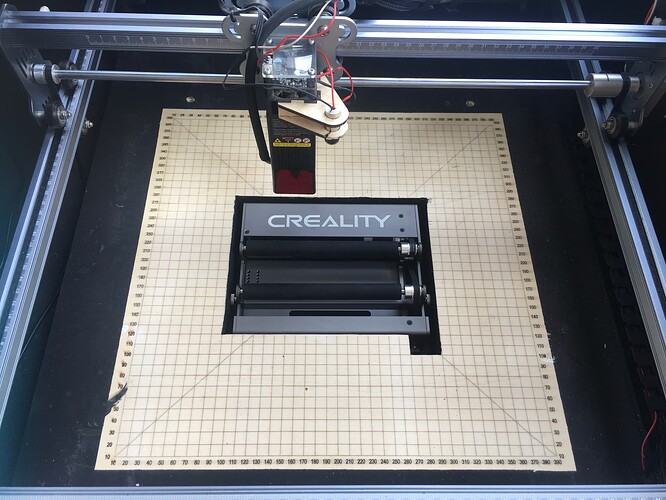

The honeycomb sits on an elevated pin-registered board with a grid that’s easily lifted.

Under the board is the rotary roller in a fixed recessed position.

I can’t upload more than 4 photos so I had to merge some…

Air assist and Comgrow air purifier. I can’t drill holes in my apartment so this was the only solution for the cold months. I can smell the burn on long jobs but otherwise I’m kind of happy with it.

Falcon doesn’t have a dedicated port for the rotary so I’ve put a switch and connected the cables to the Y-axis.

My preferred place to work is about 7 meters away from the laser and the most annoying thing was going back and forth when I wanted to frame or place the material, so I got this cheapo keypad, spray painted it, then engraved it. I’m using Karabiner to map the shortcuts. I can share both code for Karabiner and Lightburn project if anyone is interested.

I tried to go wireless via the Rpi route that many have succeeded with, but the Falcon is stubborn and refused to work properly. On hindsight I’m happy it didn’t, I wouldn’t trust doing long jobs wirelessly only to get hiccups a bit before the end. I bought this 10 meter USB extension that has the laser, keypad and webcam on it and works flawlessly.

I’ll be adding a magnetically attached cover to the laser head, I don’t see any point in it being exposed. Even through the dot is very faint going through the head’s cover and the orange plexiglass of the enclosure it’s still dangerous, the laser sits in my living room and my kids are always excited to watch it do its thing-never without glasses though:)

I’ve posted a request for Lightburn to have the ability to run an AppleScript or anything similar at the start of a layer, that way I could send a signal to a midi-enabled Arduino and start the air assist automatically, this is the only annoyance I have at the moment, having to stand by the laser and wait for the engrave layers to be done, then turn it on, grrrr…

That’s it, this is my first laser, I’m happy to be part of this community and rest assured I’ll be asking plenty of questions in the near future:)