My Atomstack A5 Pro+ rams into the corner (lower left) at every start-up. It “grinds” into the corner for 3-4 seconds. Also, when engraving, it always seems to start the laser process along the bottom edge, which “rubs” the air hose along the framework. I’d like direction to 1) stop the grinding into the corner; and 2) have my project engrave in the middle on my workspace. I am a total Newbie, so please use small, understandable words…thanks.

I believe your laser does not come equipped with limit switches to allow for homing. Homing is used to establish a known good position, typically 0,0.

Because you don’t have limit switches for this you need to do this manually. While the machine is off, move the laser head to the front-left of the machine. Then turn on the laser.

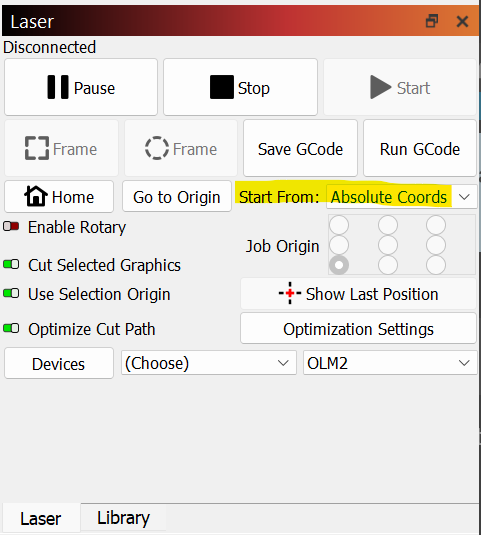

Until you’re very familiar with the functioning of your laser I recommend you stick to “Absolute Coords” as the “Start from” mode in the Laser window. This will basically make is so that the position of objects in your Workspace match the physical location on your laser bed.

In order to engrave in the middle of the Workspace place the object in the middle of the workspace which will then correlate to the middle of the bed of your laser.

Thanks… REALLY, thanks. Next, you said to “stick to “Absolute Coords” as the “Start from” mode in the Laser window”…sorry I don’t know where that is. Which drop down window do I go to? While you’re here, How do I set the “minimum” power. It appears that I can change my MAX. POWER to 100% for cutting, but I feel I need to set the minimum power to 100% also, but it is now where to be found. And, does “air assist settong” aid or interfere with cutting through wood? I do have a seperate air tube connected to the laser.

Thanks again for your help.

In the Laser window, usually at bottom right, there is a field that indicates “Start from” with a pulldown. Set the pulldown to “Absolute Coords”.

There is no control for minimum power for grbl lasers for most operations with the exception being for grayscale images. Is there a reason why you feel like you need to set minimum power?

Outside of the basics of proper focus and having the right laser module and lens air assist is the single biggest aid in getting a clean efficient cut.

Thanks so much for your quick response, amazing. I thought setting the minimum at 100% would help me burn cuts better. Sometime i can get through 1/4" wood with 8 passes, and sometimes 15 passes doesn’t cut it. (speed 2.5 mm/min)

This assumes that the laser is not actually running at 100%. Power is actually reduced dynamically to account for deceleration/acceleration scenarios in hardware but is otherwise commanded to go at 100%. You can prevent this behavior by using “Constant Power Mode” in your cut setting. This is generally a bad idea as it will cause scorching in corners but maybe something you want to experiment with.

What kind of wood is this? Variability in this is most likely caused by variations in the material itself. If this is plywood then that’s a whole different thing. Ply is inherently difficult to cut and ply quality will make a huge difference in cut performance.

Make sure your focus is tack sharp and that your lens is clean. Those make an immense difference in performance.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.