I searched the topics and found similar threads but none matched my specific issue.

This is the background of my situation:

I have an XTool D1 10w and the latest version of Lightburn. My machine settings/origin settings were bottom left and on laser settings I had Start From set to Current Position and Job Origin set to bottom left. Everything worked as it should. Then I bought a CO2 laser with Ruida controller. I had to upgrade Lightburn to the DSP version. I installed the new laser (Gweike Cloud 50W) and had many technical difficulties. I was able to get all the move, and frame functions to work but the laser just would not fire. It is now sent back for replacement. So now I went back to my XTool D1 and had to reset the configuration settings to what I had for the diode laser. When I frame the boundary of a test, the laser head moves in a clockwise direction, but starts from top left instead of bottom left. I have closed, restarted computer, restarted Lightburn, but didn’t uninstall / reinstall Lightburn. I also noticed that in the Edit tab at the bottom, there was no Machine Settings choice, only Settings and Device Settings. I loaded a preferences backup from prior to making any of the above mentioned upgrades and changes and it restored the Machine Settings choice on the Edit tab, but the origin is still inversed. The image is not inverted, and all the move buttons move in the right directions. The test burn also was oriented properly. I changed the origin in Edit/Device Settings to upper left and now the frame and burn are properly oriented. (This was a fix in a previous thread)

My question now is how do I restore it back to the way it was before, with device settings origin at bottom left and job origin in laser settings at bottom left? This new configuration seems like just a workaround and not a solution to the root cause. Any help is appreciated, I think there are a lot of us having this same problem.

The configuration settings should not have changed when you added the Gweike. Did you delete the D1 at that time? You can have multiple lasers saet up in Lightburn. Each configuration maintains it’s settings when you switch between them.

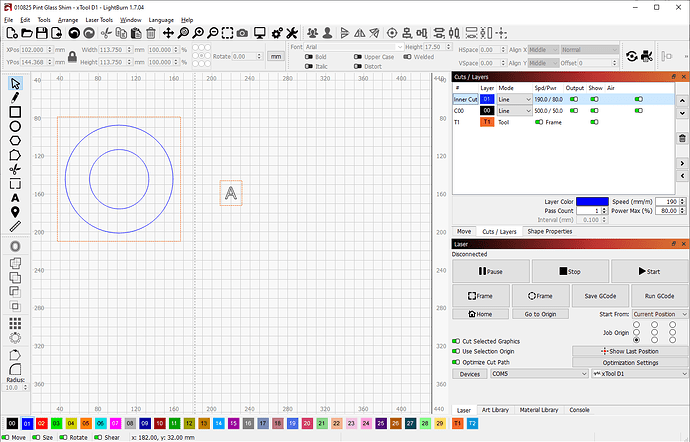

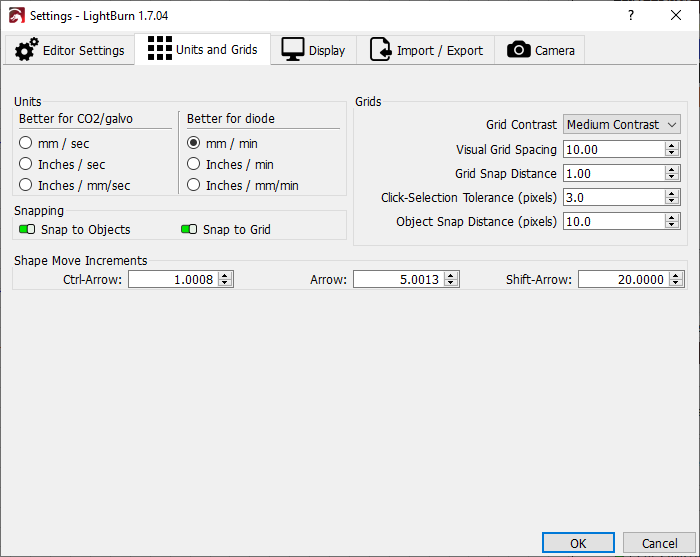

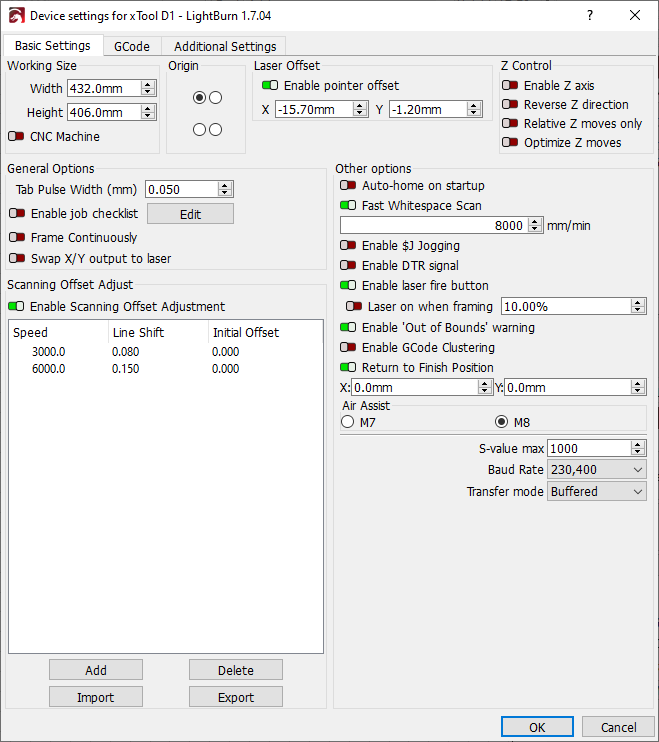

All that being said, I can’t see your system so please post a screenshot of your entire Lightburn screen with your project loaded and the Cuts/Layers Panel and Laser Panel visible. Also post a screenshot of the Settings Window (Gears icon) with the Units and Grids tab visible and post a screenshot of the Device Settings Window (Wrench and Screwdriver icon).

I run the little A as a test to see if anything is inverted in the display image or the burned result.

The previous Origin setting was bottom left, but now I have top left in order for it to work the way I want. I prefer the origin to be bottom left because that is how my CNC is programmed.

The main computer I use for my work is a desktop unit. I also have a laptop for backup. The same effect happened on my laptop after adding the Gweike. I have deleted the Gweike from both computers, but have not tried uninstall/reinstall Lightburn.

Everything I’ve seen indicates that top left is the Origin location for the D1. You cannot change the machine origin. It is built into the firmware by the manufacturer. I not sure where the Gweike homes to, but I think it’s top right.

Each machine has it’s own configuration file, so they do not have to be the same. Not sure what you would have had to reset in the settings unless you deleted the D1 when you installed the Gweike.

You have the home position set properly and you said it’s cutting in the right orientation. What other issues are you having?

I appreciate your help on this issue. It seems strange that before I had both device origin and job origin on bottom left and all was well then something changed that I am unable to restore. Now the fix is to change device origin to top left and keep the other one on bottom left, ok I can live with that.

As for the Gweike, that’s a whole different can of worms. I had all the navigation functions working, and it would frame the boundary of the test, but would not fire the laser on start. I spent 3+ days with tech support, testing circuit continuity, applying jumper caps to bypass two connections, refilled the coolant tank and lots of brain damage from frustration. That unit is being sent back for replacement. Hope the new one works. Just wait for my Gweike review. Right now I’m not a fan of their after sales support.

Thanks again,

Cheers

I can all but guarantee that you had the machine origin set to top left before, otherwise all your projects would have been mirrored one way or the other.

This is a video I made that explains the differences in machine origin, job origin and the different start from modes. It may help your understanding.

I will study that for sure, thank you. One other question, regarding rotary engraving. If the object is tapered, I assume the narrow end needs to be shimmed up to make the surface level. My idea is to make a doughnut like shim for the small end, is that the generally accepted method?

What type of rotary do you have, chuck, 4 wheel or 2 roller?

It is the two roller type.

With the 2 roller, the donut on the skinny end is a good idea. I would shim under one end of the assembly to get the tumbler level as well.

That’s a good idea. Scrap wood shims under one end seems too easy. I would feel compelled to make a jig with a couple of interchangeable cams for variable adjustment at different heights. ![]()

Sometimes my jig making is more work than the project

This topic was automatically closed after 30 days. New replies are no longer allowed.