Want to run LightBurn software.

Primary use is for cutting 1/8" plywood.

I would like to keep the price around $1,000.

Videos on YouTube appear to be little more than commercials. ![]()

Hey Ken. At your price point and needs there’s really only a single practical choice which is to get one of the many K40 variants.

Once you purchase the laser, LightBurn compatible replacement board , accessories, extra parts etc. you’ll easily be at that $1,000 budget.

Not sure what the size of the material you’re hoping to cut but typical area for a K40 is 8"x12". There are modifications to eke out a bit more size.

You may be considering a diode laser right now but I would dismiss it if your primary use case is cutting 1/8" plywood. It can be done but you’ll be fighting it the whole way.

I am hoping for a work area of at least 18" x 24". Thanks for all the info - I will begin looking at the K40s.

18" x 24" will take you out of the K40. Even with mods you won’t be anywhere close to that. I’ve seen full rebuilds of the K40 that go to 12" x 24" but that’s pretty much it.

That size requirement will also take you out of any commercial offerings that I’m aware of. Those will typically be in the range of 3-4 times your budget.

Realistically you’ll probably need to compromise on some of your constraints… either size, budget, or expected operation.

Hypothetically you might be able to get close to your budget if you went a full DIY route but would be tight and with some potential compromises to keep costs down.

Most of the Chinese machines, excluding the K40 have a materials ‘pass through’ in which you can do larger pieces than is normally allowed. I use it quite regularly as mine is a 500 x 300 machine.

These can be had for $1500 - $2500 depending on options. I’ve modified mine and it’s 508x342 now.

To do this is tricky, as you have to figure out how to create ‘parts’ of the completed project. It’s how you cut it and lay it out. Even my machine is smaller than you want and above your limit money wise.

The options are generally increase the budget of lower what you can do.

As @berainlb pointed out, diy is always an option.

Good luck

![]()

Options: I guess I will outsource my parts for 3D printing until such time as the Maker Space I belong to upgrades the software for the (large, but OLD) laser that is in the shop. It is sad that nothing I find on Amazon has at least 7W output; or good reviews. Amazon.com

There are plenty of competent diode lasers and a lot of conversations about those on this forum. They can be fantastic for where they fit well but just not a great fit in your case since cutting 1/8 in. plywood is your primary use case. It’s possible you could get a diode laser to cut through it but it’ll likely be extremely slow and unpleasant.

If you have any ambitions for engraving or cutting thin solid woods then a diode laser could be a great stepping stone for where you want to do. It would also give you a vehicle to skill-up on LightBurn. Diode lasers can actually have an advantage when it comes to fine engraving capability and can more readily offer you the size that you’re looking for well under your budget.

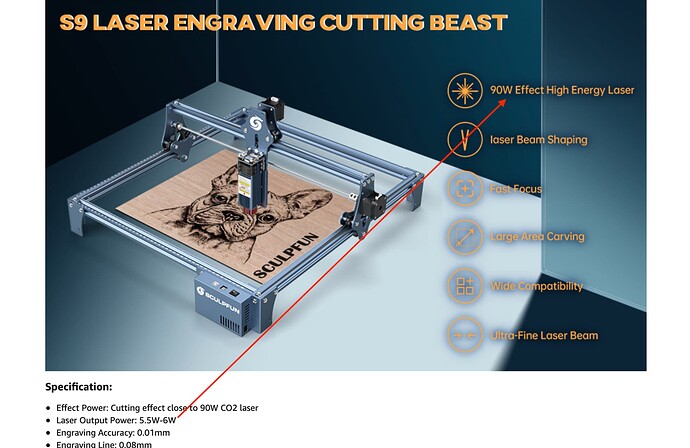

I just picked up the Sculpfun S9 diode and I do like it a lot. They offer a bed extension to size it out to 950x410. Amazon.com: SCULPFUN S9 Laser Engraver, 90W Effect High Precision CNC Laser Cutter and Engraver Machine, Deep Cutting for 15mm Wood, 0.06mm Ultra-Fine Fixed-Focus Compressed Spot, Expandable Engraving Area

It is a beautiful machine and the data is also very impressive.

But, allow me to ask, has Ohm’s Law been changed or have there been any other great inventions in the time I’ve been out for coffee?

I do not want to ruin the good mood for the new machine but I do not understand how stupid some manufacturers think we are.

Maybe 90W is the power going INTO the laser, not coming OUT of it. ![]()

Larry:

Thank you for the suggestion. May I ask have you tried any serious cutting with it ?

Ken

Hope not I was misunderstood, it is not my intention to talk bad about diode laser, certainly not. It’s just not necessary to advertise this way. People who do not know anything about the subject think they are buying a cutting torch in the super class. Diode lasers are fine for engraving and possibly cutting thin materials such as cardboard and poplar plywood and similar materials, up to 2-3mm. (everything that can be cut with a single pass, several passes just will not be fine without lots of finishing) I speak from personal experience with a 5.5Watt diode laser)

Thanks for the heads up. I will investigate those conversations.

If I was a younger man; I would initiate a Kickstarter campaign to take the best available diode laser and work with the manufacturer to permanently fix whatever issues that unit has. Sadly, I am a bit late to the party to go that route.

Unfortunately, it is not that easy or a matter of money. Diode lasers have their wavelength which gives them the possibilities they have, and it also makes the laser beam just go through glass or acrylic.

The new diode lasers with 2 diodes and with a total power of approx. 10-12 Watt, they are reasonably potent to also be able to cut in wood, but the wavelength is the same, so no transparent acrylic. These are physical limitations, just as a CO2 laser (at the low power end) cannot cut into metals.

I was referring to issues like: terrible assembly instructions, software issues, units that “just stop working” after a few days, and lack of customer support. I am pretty sure that these issues could be fixed - if the manufacturers wanted to do so. ![]()

Since you are a newbie you might need a bit of learnin’ on terminology. We make a distinction between “cutting” and “engraving”. Most of what is done on plywood in engraving. If that is your primary use, not cutting, then a diode laser is within your budget. When it comes to cutting, diodes will do the job, but it takes multiple passes. The forty watts of a K40 is plenty of power for most anything, but its limitation is its size. It’s just so small. When I got my laser I already had a lot of experience with a 50 watt CO2 laser, I wanted to cut standard size craft materials that often come in 9" x 12". I ended up with something a wee bit larger because there is a big gap in CO2 laser sizes from a K40 to a 50 watt laser. Get on Amazon and ebay and check out the sizes of the material you intend to use, shoot for that as a size. P.S. I have problems engraving small stuff, so I am building a 7Wattt diode laser system to help out at the small end. Oh, CO2 lasers have a minimum power below which they just don’t fire, mine is 9% of 50 watts.

Thanks for the clarification. As a newbie I definitely have a LOT of learnin’ to do. ![]()

Buy a Glowforge, customer support, warranty…

All that costs money, guess who’s paying the tab?

![]()