I found this second hand láser at a bargain price and not far from where a live, I can go and check it myself. I’m not an expert in big machines like this one and I never used ruida machines before, the only 2 machines I ever owned are a DIY grbl 90w and k40.

I went to see the machine 2 days ago but I couldn’t test it because the owner was busy and we arranged another day for testing, he told me that he never used the laser and that he got it from a factory that barely used it and that it was part of a payment the factory had to pay him. He gave me the green light to test anything I want for a full day from 8:30am to 6pm before buying it.

First thing I noticed when I briefly saw it:

- Well preserved for a 2017 second hand cutting machine (7 years).

- The machine factory date is 01-2017

- The laser tube factory date is 08-2020

- Laser tube power: 130w

- Laser tube max power: 170w

- bed working area: 160 cm X 100 cm

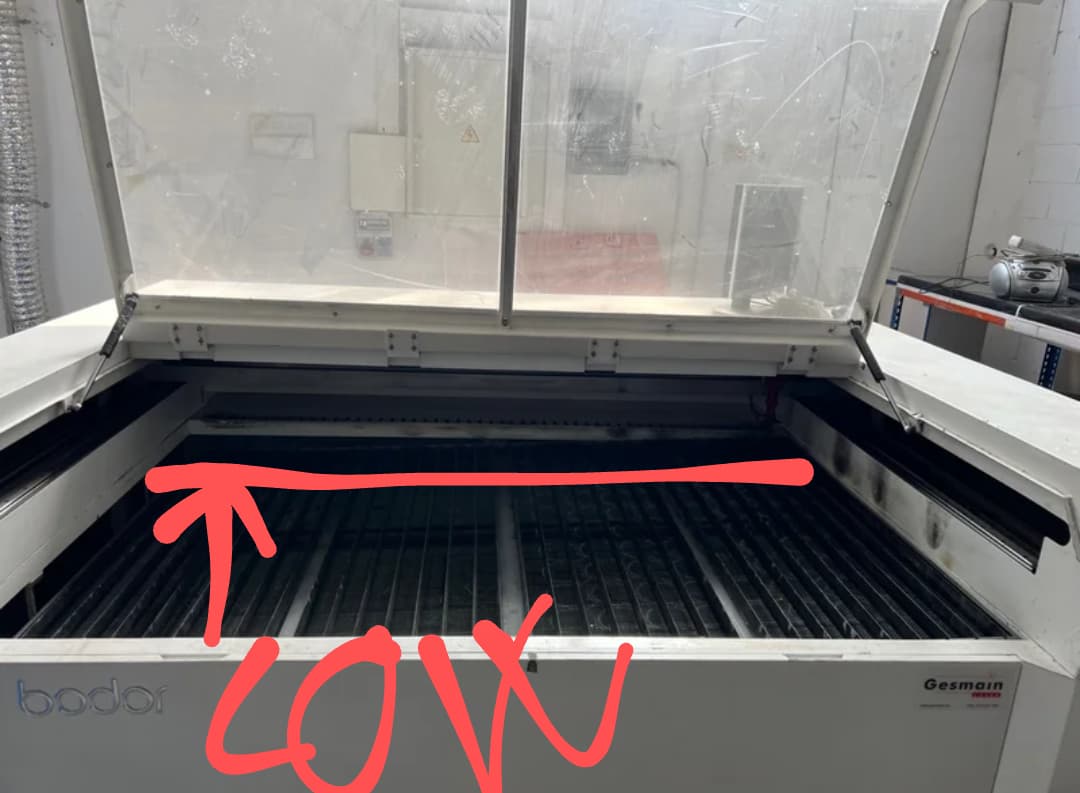

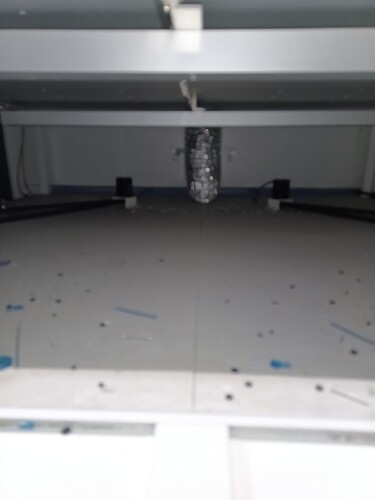

- The bed is not leveled from the left side (looking at the machine), the lifting mechanism is split to two stepper motors one controls the left side and the other the right side of the bed, each has it’s own belt. (I attached pictures showing the tilt in the the bed and lifting mechanism)

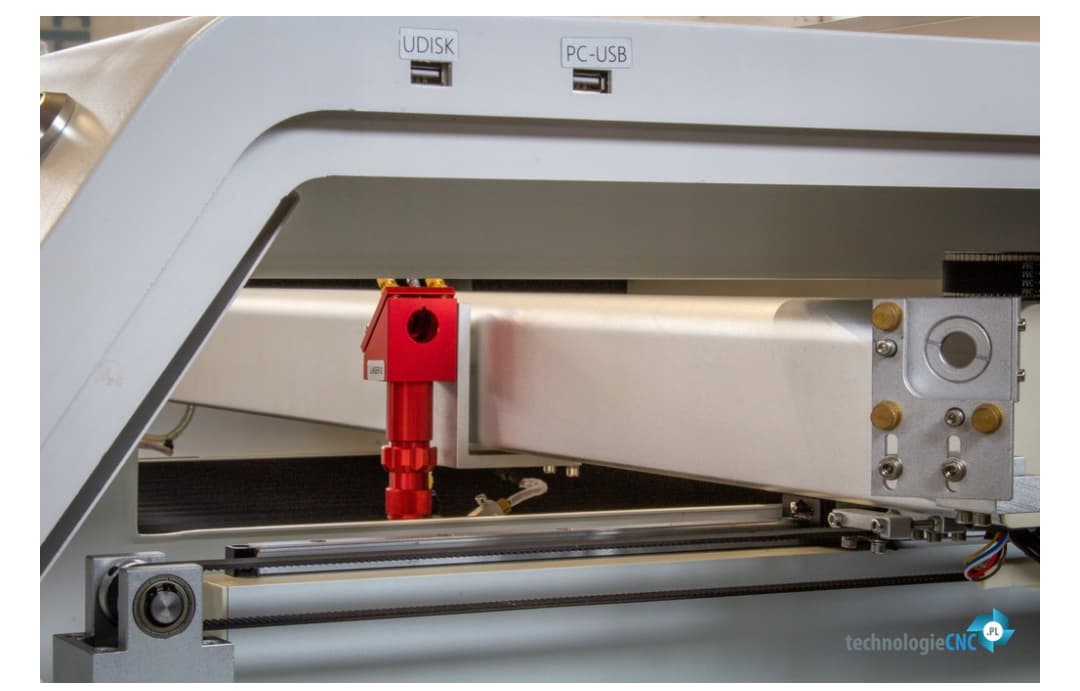

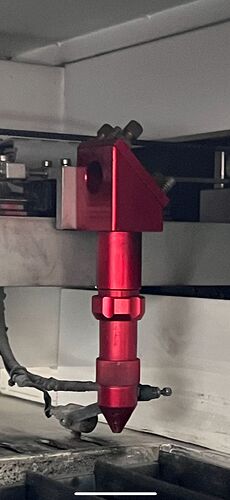

- The gantry is different than the pictures and videos I’ve seen on the internet about the same model. (I attached picture the first pic is the machine gantry, the second pic is from the pictures I found on the web)

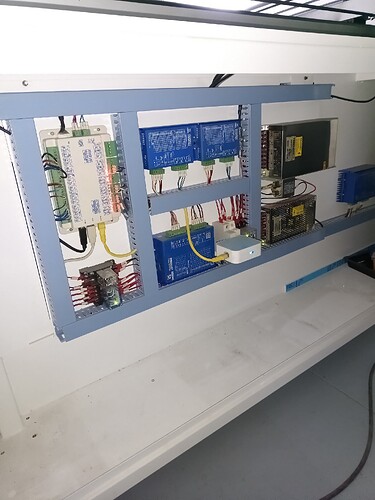

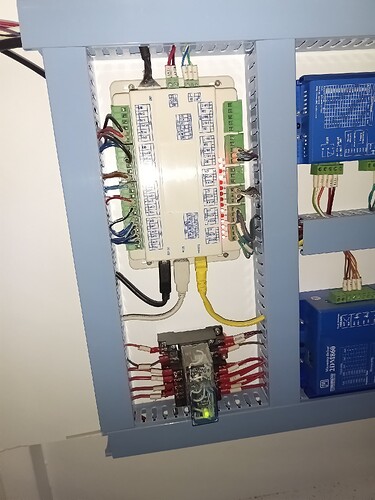

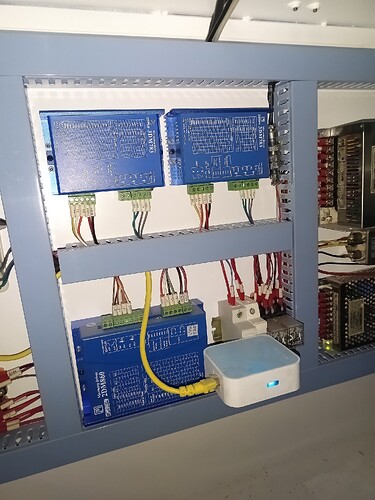

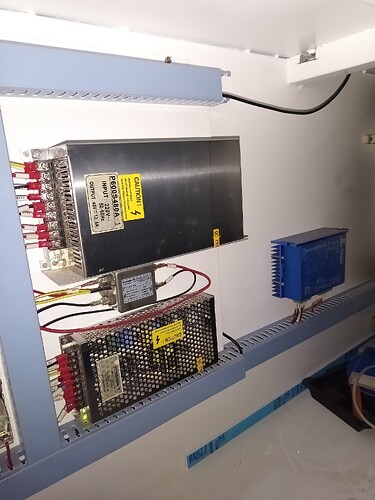

Some pictures of the machine and it’s electronics:

The point of creating this topic is to gather as many advices as possible from the community about things I need to test and try before buying it.

Any piece of advice will be much appreciated and helpful.

Cheers