I’m finally up and running with my Eleksmaker A3 after getting great help from the kind people on here. I decided to do a quick engrave of a Citroen 2cv just on paper to test it, all started well as I watched in awe as it did it’s thing, then it looked like it was coming back over where it had already engraved (I’d just had a problem with the Y axis) so was scratching my head a bit wondering what was going on then I noticed the cable for the laser was resting on the paper and moving it as it moved back and forward on the paper  So tomorrows job is to sort out the cable management !!

So tomorrows job is to sort out the cable management !!

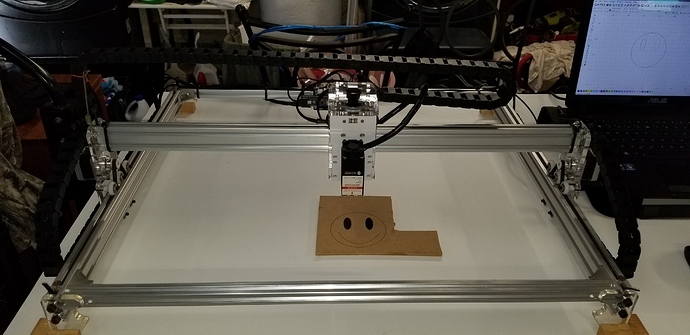

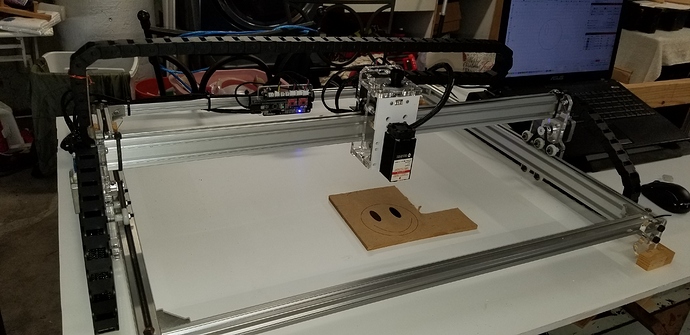

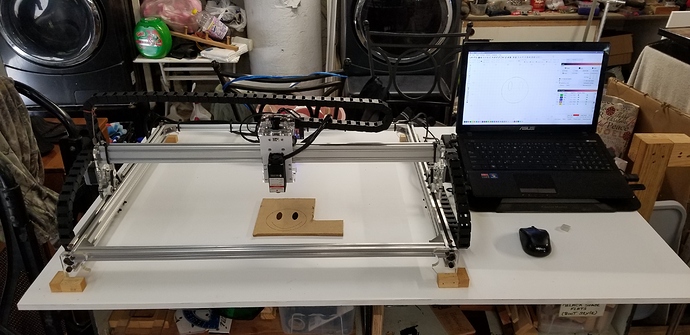

I bit the bullet and made longer cables to make use of drag chains. This keeps the cables out of the work area, and the drag chains keep the cables tidy and flex with the movement of the gantry. Figuring out how and where to mount the X axis chain was one of the most difficult aspects of the job. If you’re going to make your own cables, you’ll need JST connectors in 2.54mm pitch for the controller ends, and 2.0mm pitch for the motor ends. A JST pin crimper is a must too. 26ga. wire for the motors, and I used 20ga. wire for my power and PWM connections. Braided sleeving for your newly made cables is optional, but helps keeping the individual units separate.

3 Likes