Hey,

I recently bought a Neje N30820 30W laser. I connected it to my cheap 3018 CNC (had to swith TTL and GND on the board connector) and started reading a lot. The 3018 I have comes with the Woodpecker CAMXTOOL V3.4 board. As far as I can tell, this board has a ATMega 328, so it’s 8 bit.

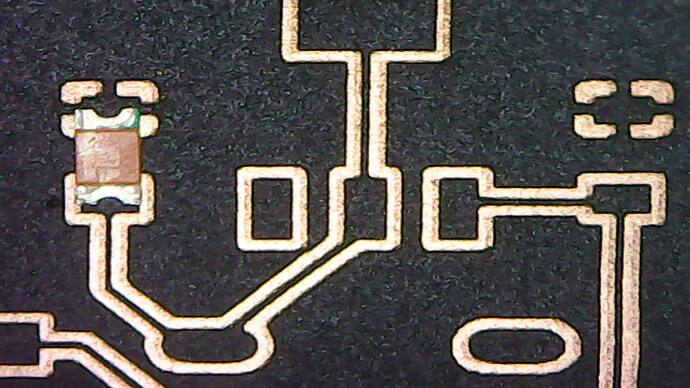

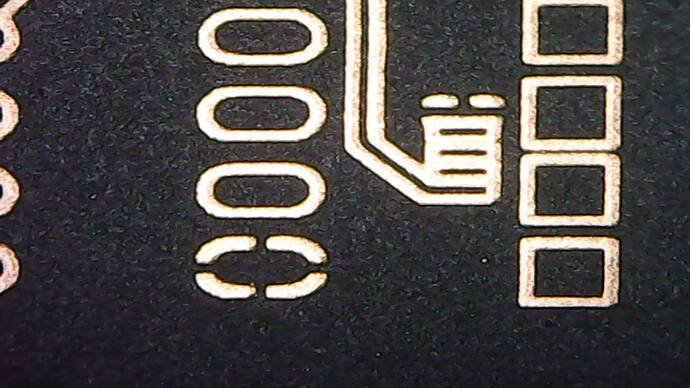

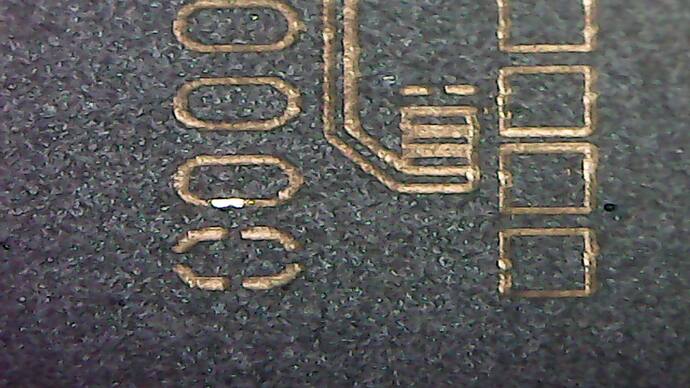

I already tried it out, but my results were not so good. The main purpose for me is creating PCBs by the “spray-paint and etch” method. During my tests and during reading all kinds of documents (I already checked the “Configuring a 3018 CNC…” tutorial here) and came across a few questions and I hope someone can help me out here.

-

According to the configuration tutorial mentioned above, 8bit boards can set the power only from 0-255, but when reading the settings with “$$” it shows the value 1000 for $30. So how would I have to set the power now? Would setting “M3 S200” be 20% or ~80% ?

-

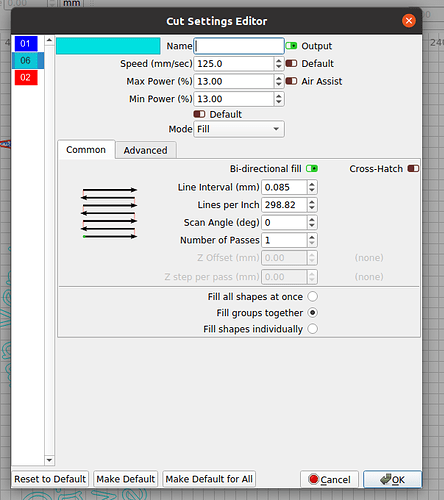

What would be good values for etching a spray-painted PCB? I have absolutely no experience and would love to have some starter values for power % and speed.

-

Since I’m currently on Linux, what would be the best way to create a gcode file from a eagle layout? So far, I’m exporting the schematics to image, open that with inkscape, and the export it using the LaserPecker extension.

Thanks in advance.