New Neje Master 2S user with 5/20W laser module. I am trying Lightburn prior to purchasing…

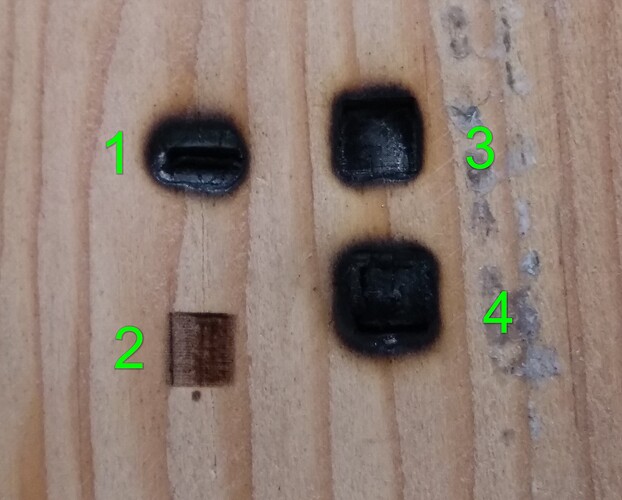

My issue is that the power output is terrible. To demonstrate, I’ve burned a stamp using the Neje phone app and Lightburn (sorry about the other rubbish on it - wood is in short supply at the moment).

The top example is via the Neje app, the bottom via Lightburn. Neje setting is speed 9mS (whatever that is) and 31% power, and it took 01:46. Lightburn layer is set to 6000mm/m and 100% power, and that took 01:30.

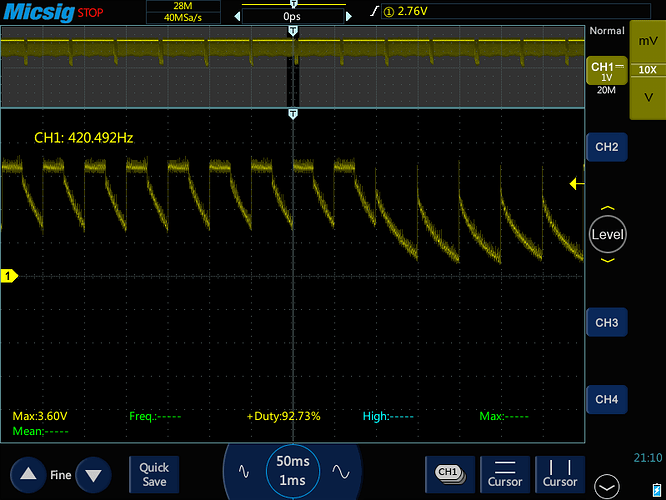

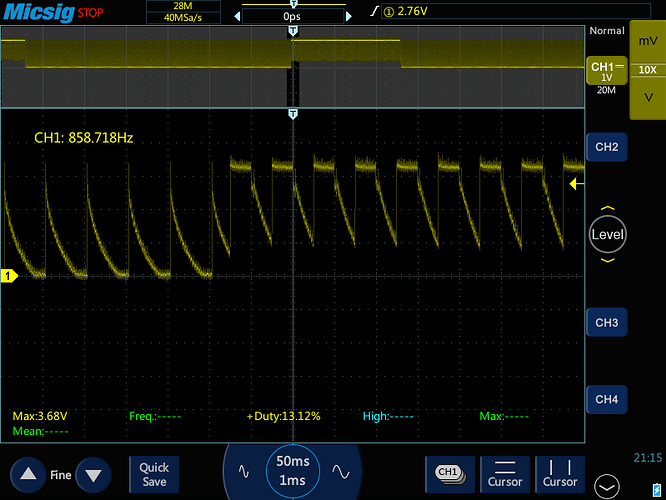

You can see the dramatic difference. The beam is noticeably not as bright when it’s happening too. I have searched for any reference to this kind of discrepancy and the only one that seems relevant turned out to be using Benbox instead. So here is my $$ settings:

$$

$0=10

$1=200

$2=0

$3=7

$4=0

$5=0

$6=0

$10=1

$11=0.010

$12=0.002

$13=0

$20=0

$21=0

$22=1

$23=1

$24=100.000

$25=1000.000

$26=250

$27=1.000

$30=1000

$31=0

$32=1

$100=80.000

$101=80.000

$102=80.000

$110=4000.000

$111=4000.000

$112=4000.000

$120=200.000

$121=200.000

$122=200.000

$130=170.000

$131=170.000

$132=150.000

ok

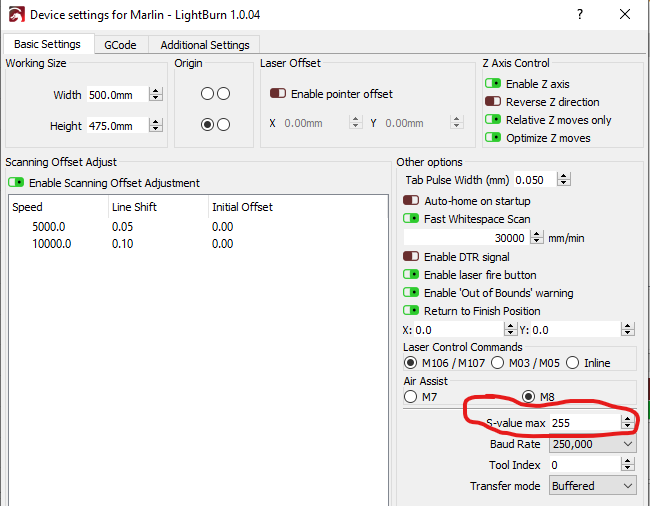

S-value max is set to 1000, which matches $30. Can someone tell me what I am missing (hopefully something simple) or how to otherwise fix this?