Hello everyone, I wanted to ask why under the laser device put a mesh or mesh challah?

I’m not convinced that the ‘honeycomb’ engraving bed is the best choice. There is growing concern that it collects condensate or vapour that can solidify. Resinous condensates can be flammable like chimney creosote.

Got tons of experience with our Makerspace running honeycomb for many years.

There is no “danger” except for small debris that may fall through and accumulate underneath and fuel a fire if the situation is GROSSLY neglected.

The residue left on the honeycomb itself is only a concern for staining the underside of the work. I have never seen it appear as a fire hazard because what we had was not thick enough to sustain combustion once the beam left it.

It is one of 3 sources of bottom marking- old residue from wood/acrylic, beam reflection, and the blast from the current cut. Setting the work up on pins so it’s not resting on the honeycomb- thus mostly defeating the convenience of having a honeycomb- resolves the first two problems but not the third.

Steel honeycomb can be cleaned with pressure washer and/or oven cleaner. Aluminum honeycomb generally cannot. A pressure washer will generally bend the cells of aluminum and destroy it if the nozzle is close enough to peel off the soot. Oven cleaner is a strong alkaline solution- lye (sodium hydroxide) IIRC- and aluminum starts fizzing as it dissolves it. It’s pretty thin aluminum so it’s hard to get a useful window where soot is removed but the aluminum is not seriously degraded.

I would never use aluminum honeycomb again. Steel is far superior in many ways. It is much flatter, for one.

My honeycomb is somewhere in the garage, I haven’t found a use for it, but haven’t pitched it knowing how much it cost.

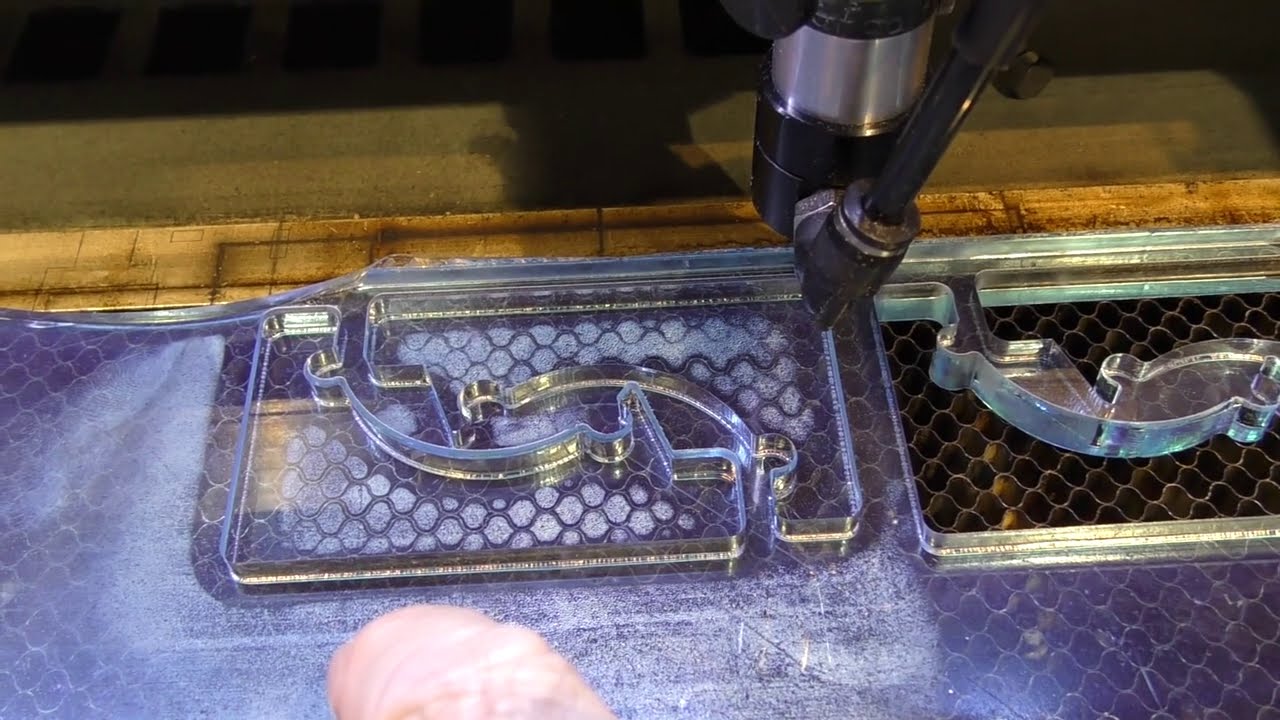

There is clearly no advantage in removing the debris/gas, as you can see from the many videos taken from underneath or through some clear acrylic.

If your part does not cover the whole honeycomb you have to cover it or all the air volume goes around the material and surely not through that tiny .1mm cut. Like much of any can get through it anyway.

Cleanup is easy on a sheet of rolled steel. A little rubbing alcohol or acetone and the bed cleans up quick and easily with just a rag. It doesn’t sit there and stink up the machine or garage like the ones I’ve seen. No need to take it someplace to soak it, or extra equipment to clean and dry it.

You may not have a problem but I know of no laser fires that were not somehow related to the honeycomb ignition of debris and more than not acrylic. They are bound to be out there, but I’ve never heard of any.

Made a trip to Phoenix last week to get some ‘low cost’ acrylic from a plastic company. Couldn’t speak to the owner but went by and met him. He gave me quite a nice stack of acrylic. When I asked to see his machine, he looked at me sheepishly and stated ‘It burned up’, asked to see it anyway.

He was running acrylic job on a honeycomb bed and within 10 feet when it ignited. It got so hot so fast he had problems getting the lid open.

So we’ll have to agree to disagree…

![]()

What’s your alternative? If we run a knife table, we still have the same consequences if we’re using downdraft exhaust and don’t cover the unused work area. Actually covering isn’t essential, we never do- but smoke removal is certainly less than perfect.

The air assist jets air through that cut, provided you’re going through. We usually 1-pass successfully and the smoke ends up under the honeycomb and the exhaust is mostly effective at pulling it out before it leaks back through.

When you do use honeycomb, you can still add little pins to stand the work off it and not have the drawbacks.

What I dislike about knife tables is that small parts easily fall through, or one end can fall leaving the cut piece tilted. The beam may still hit them and it’s unfocused, so it may set it on fire rather than simply making another cut in it.

My perspective is for a Makerspace- a large body of users with a wide range of technical skill. As such, the more approachable and general purpose solutions are always preferred.

The steel honeycomb with the smaller cells has by far been the best utility. We screwed around with aluminum honeycomb for years, there’s just no comparison. A few people need their work’s bottom surface to be absolutely clean, and those people typically bring spacers or build a small stand for the sheet. Even a 1/4" spacing is enough to keep the bottom clean. And when a part cuts out, it will simply fall straight and flat with no displacement because the honeycomb surface is right there.

One guy here just took “spikes” that screw into leather for punkwear (or fetishwear) and screwed them onto little stands so you can just stand the spikes on the honeycomb for these times when you want a pin table. Takes seconds to set up and then break down for the next user.

I have these punk spikes and am very happy with this solution, reflections I do not experience.

I would like to point out that my steel plate from picture no. 2 can easily be hung under the knives with simple hooks, no items are lost. But I have made a permanent plate between the knives and the mechanics of table height adjustment. A picture of it is here on the forum somewhere.

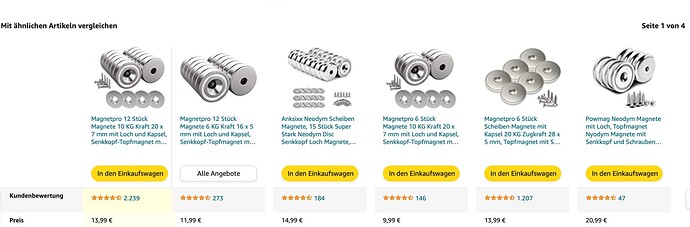

Where did you get those?

Do you make those?

Always open to try something different…

![]()

The spikes and magnets are from Amazon. I have spikes in 2 different heights, 9 and 23mm, the magnets are ø20 and have a submerged hole. The screws are included with the spikes. The magnets are very powerful -10kg.

Thanks… I will see if I can get some ordered…

![]()