OK, now that I’m awake …

IMO, the only disadvantage of twiddling the knob for each job is that you’re depending on remembering to set it right every time, which seems unlikely in the long run, and you’re giving up the ability to automate the current for different layers.

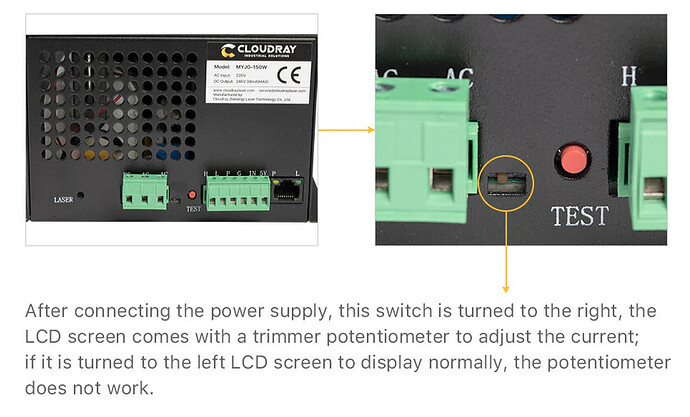

I have a similar remote display for a 60 W Cloudray supply, but (as described in the doc) the knob works only for supplies over 100 W with an internal switch enabling remote control. From what everybody with such a supply reports, the knob scales the current between zero and the maximum set by the supply’s internal trimpot, which is what the supply delivers without the remote display / knob.

Given that the supply already has a current control loop based (AFAICT) on a sense resistor in the cathode lead, the switch inside the supply probably selects either:

- The output of the feedback control amplifier

- A fraction of that output set by the knob pot.

That signal then controls the tube current as usual, so the knob can only reduce the current.

With that in mind, I think it makes more sense to use LightBurn’s control over the current / power limits, because then the project includes all the information required to run the job without having to twiddle the knob to suit.

For example, my LightBurn job for a set of earrings has three different PWM values for shapes on different layers:

- Milling a rebate around the rim

- Kiss-cutting a surface reflective layer

- Cutting the perimeter

With the power supply’s internal pot set to the tube’s maximum current, a single job applies the appropriate currents (and speeds) without manual intervention. It’s not clear what advantage a knob would bring, as I rarely need to change the power during a job, and reducing all three powers by the same percentage seems like it wouldn’t produce consistent results.

In fact, I rarely want to change the power, because I’ve already put the lowest power to achieve the result in the Material Library, based on previous tests. So, using your example, I select Art Paper or Cardboard → 3.5 mm or Acrylic → 1.5 mm to apply the appropriate power for whatever I’m doing, with no need to remember any of the numeric values.

But, for sure, other folks do it differently!