According to the ‘science’ journals on-line, Ethanol or Methanol are the suggested solvent. I tried Ethanol but it evaporated so quickly it plugged up the air brush. The potential is there with water if too thick or left in the brush. I also put red food coloring in it, surprisingly it was what came out of solution. If you let it sit it will separate, just like it did to me with Ethanol.

It will pool about as easy as Ethanol also. I think that’s the lines that are on the reject tile.

I live in the desert SW, so the water evaporates almost immediately and you can wipe off the TiO2 without water. Since I moved we’ve had high humidity and I haven’t broken it back out…

I have a cat that requires a 1/2 cc of medication twice a day… I use the bottle with the special top in it to store/dispense my mixture. I can shake it, draw off a few cc’s for the airbrush.

After wasting the kitchen with TiO2 dust, this keeps the mess very controllable.

There is a coating, LBT100, that is a spray, is non toxic and works relatively well, but rather expensive.

I think the warnings and suggestions apply to the TiO2 operation also. They advise the thinnest layer to get the best resolution. Too thick of a layer requires higher power and you end up with less resolution. Too thin and it doesn’t give you the deeper blacks or limits the range of the ‘dot’ intensity…

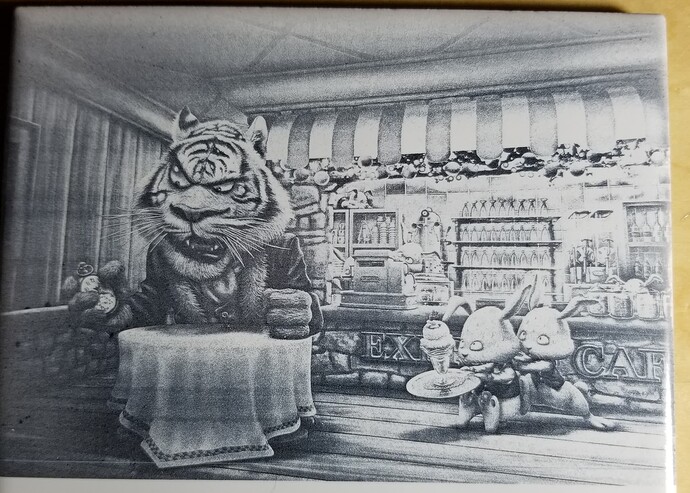

Here is one of my rejects… I think it was a combination of image quality and layer thickness for the failure.

I did get some good black, which is what I was after, but not sure exactly what how I did it. I seems to come down to the right amount of energy to cause the bond.

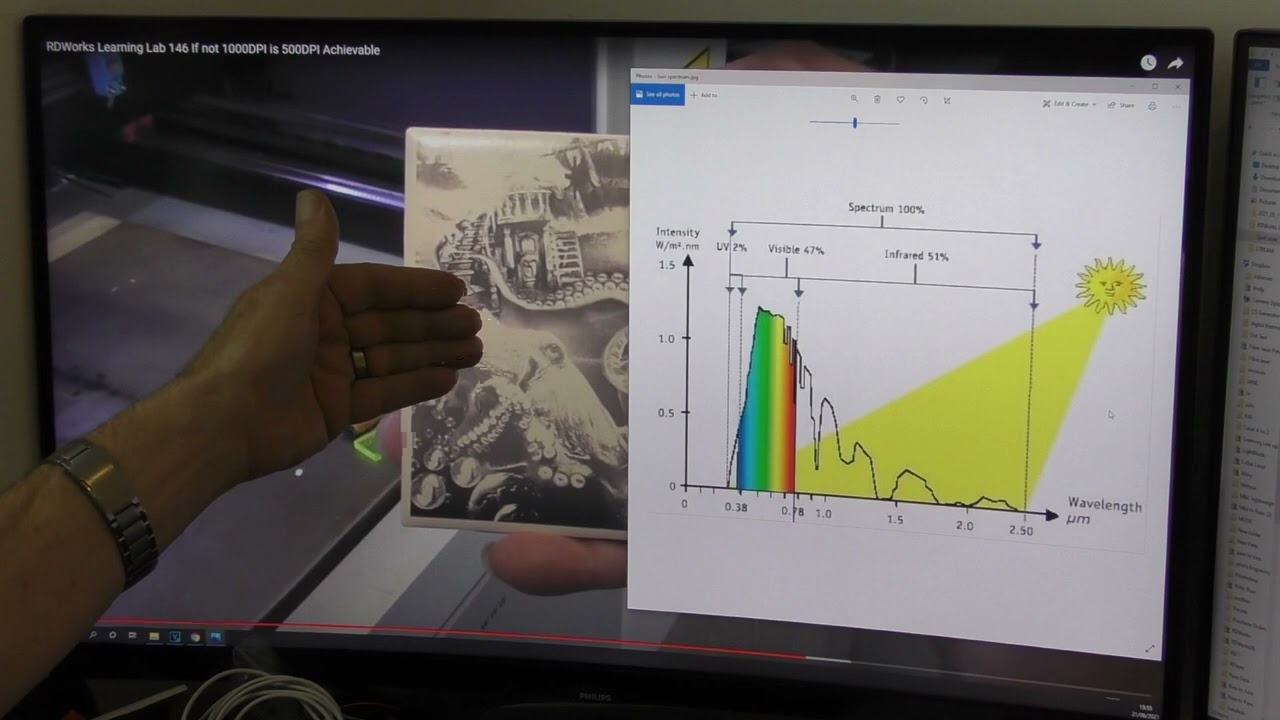

Russ Sadler has a couple videos out there on this. What I learned from Russ, was pick up a microscope. I use it all the time on my ‘laser’ stuff… On any material, I usually look at the damage…

If you look at the blacks with the microscope you can see what it’s doing to the TiO2. I think this is key to getting it working properly.

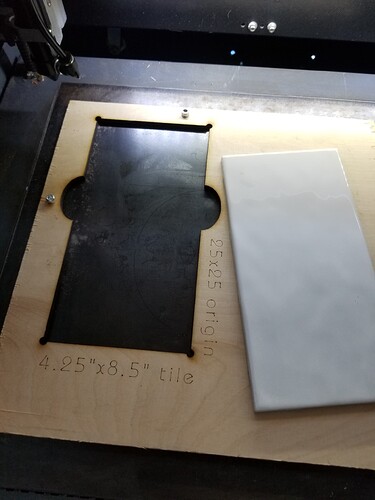

I’ve also noticed that with different tile manufacturers I seem to have different results. I’m sure it’s the material or the process they use. What made me scrutinize this more closely, besides variations in the job, was I use a jig to hold my material and my 6x6" tile from the new manufacturer would not fit… ![]()

This is a different size tile, but same idea.

This is for a 12" square mirror tile…

Here are the videos by Sadler, if you haven’t seen them…

![]()