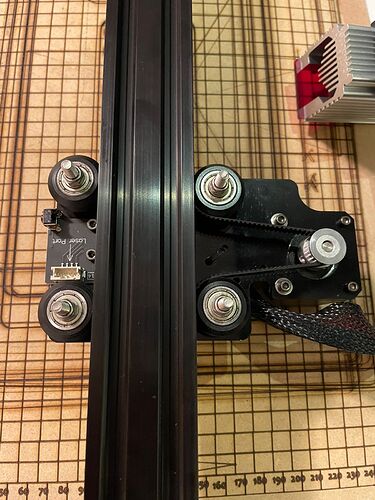

Show us an end view of that photo from both sides.

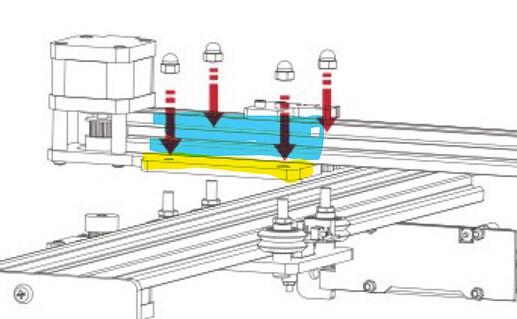

So it’s just a straight shaft for all the wheels? What material is this yellow highlighted portion?

How is the gantry railing (in blue in the picture) attached to the yellow plate?

If there’s no adjustment at all then not sure what option you’d have other than returning the machine or modifying it.

You may want to reach out to Neje support about what you’ve found and ask them if they have a remedy. I’m sure this must be a fairly typical problem.

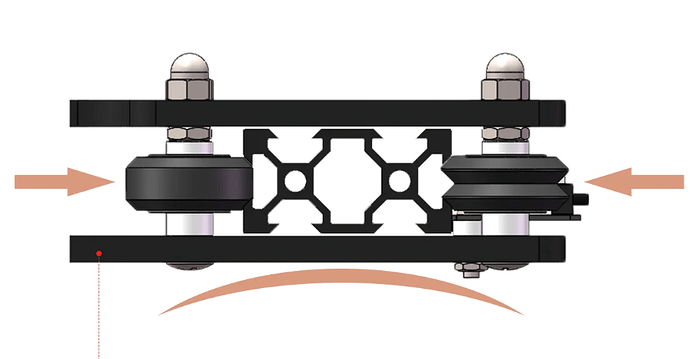

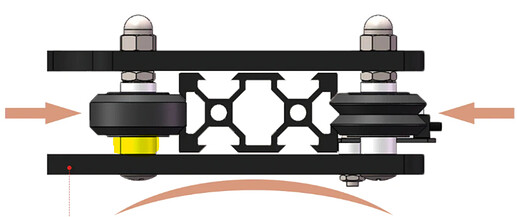

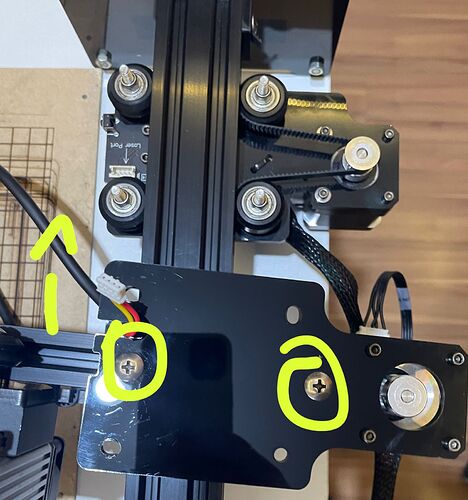

If you look closely at the top 4 holes they are elongated. For a deviation of 1.3mm it only needs to be 0.34 of a degree off square. I think with patience and trial and error you will be able to correct this…

Jim.

Good catch.

Looks like the yellow highlighted holes allow for adjustment. The round hole I assume is the pivot point.

Exactly, but not such a good system. Not easy to get perfect.

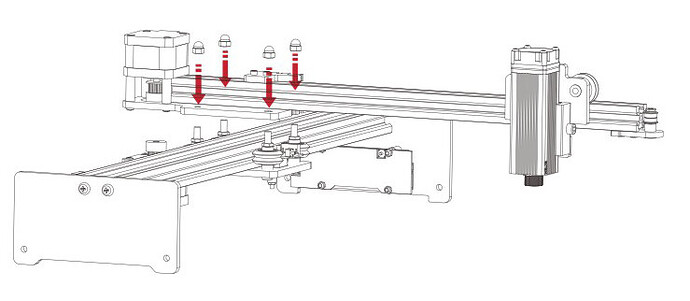

Guys, I finally got it! It turned out that these yellow holes, even though they looked like they would serve for adjustments, had a very precise fit and I couldn’t do much there, but that gave me a different idea, I unscrewed those 2 screws from the image below and managed to place the gantry a little bit aside, a few millimeters, but apparently it has improved the cuts a lot!! there is still a small offset, I would say something around 200 mm, but for my purposes, it is within acceptable limits.

@berainlb

Straight shaft for all the wheels?

→ Yes

What material is this yellow highlighted portion?

→ Some kind of rounded plastic, certainly not made for any “tuning” tool

How is the gantry railing (in blue in the picture) attached to the yellow plate?

→ Fixed by these screws that are circled in the image ( and that was the question that hit the nail on the head)

Your tip was very good, looking at the shape of the holes it looks like they were made to adjust the frame itself, you have a very good perception, I disassembled and reassembled the machine a few times didn’t even think about it haha

I would like to thank you guys for your help and immense patience, thank you very much! ![]()

![]()

In the case of a rectangle, you can also check the perpendicularity without a triangle. If BOTH diagonals are identical, the squareness is correct.

For other right angles, these can be measured using Pythagoras square root of (a² + b²) gives the length between the two ends.

It should also be noted that machines with a toothed belt drive are less accurate than those with a spindle or ball screw drive.

When I was a kid, I learned the simplicity of the 345 relationship… dad was an engineer…

Even today I use it to square things…

KISS principle seems to be applicable …

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.