Hi Everyone, I have a Hao-tian 60 watt jet mopa salvo, I have been using my 110mm lens with success, I am trying to get my 300mm lens working which is proving difficult. I understand that with the laser being further away from the material, more power will be needed but not got a clue where to start. I understand that it is relevant to the core file but I don’t have the original ezcad memory stick. can anyone help please?

If you’re certain that your 110mm lens is calibrated correctly, here’s our documentation on changing the lens:

It’s more of a focus equation I believe.

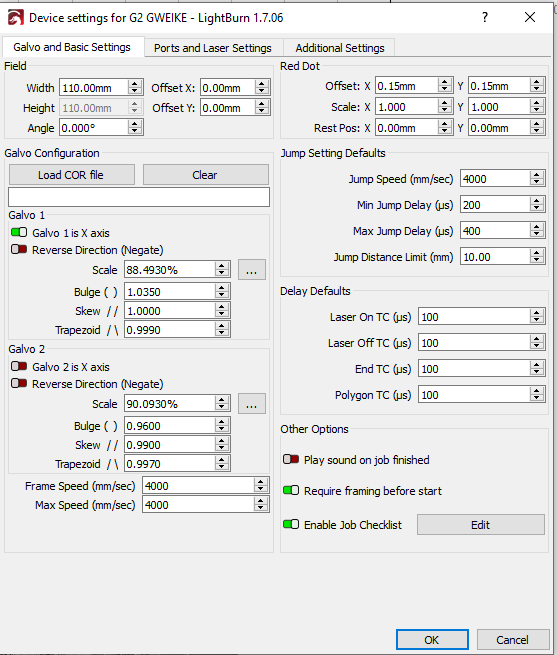

The change of the lens will change the distance required for the emission to do work on the material. You will also have to get information via testing or straight from the manufacturer regarding the lens correction data. This will be settings like scale / bulge / skew / trapezoid.

Once you do that, and have the correct focal distance from either the bottom of a reference point to your objects surface you want to interface with. There is usually a dimension from the aperture to the workpiece.

Once you have this all set up, you should have no issue with using the larger lens. I do not believe the laser will lose power over such a short distance change, but what is the most important of course, is the focal plane being so narrow that it would seem that it does not work.

In what way? Is it not engraving or ?

I don’t think the distance has a lot to do with it, in this case.

It’s most likely due to the difference in spot size between the two lenses. There is little to no power loss, just a larger spot size makes a big difference in how much heat and where you put it in the metal. Same wattage, across a larger spot, appearing less powerful…

These are the dof, spot sizes that I use for these lenses. Did them using one of the on-line spot size calculators, here’s another one.

For the most accurate, you need to know

- beam quality or M2 value

- beam diameter

- laser frequency.

- focal length

These can be found in your source manual.

| Lenght mm | DOF mm | Spot size (microns) |

|---|---|---|

| F100 | 0.740 | 16 |

| F420 | 13 | 50 |

Everything’s a tradeoff. Pick a small spot, less dof, bigger spot, larger dof.

You can engrave on a rotary much faster with a longer lens as it can stay in focus longer around the object, so you can have a large split size.

I believe the markcfg7 that comes with the machine contains many of the settings, such as timings and source type.

I think the cor file is a lens CORection file. They appear to be different.

I don’t have a cor file for my F420mm, it was stock and I only loaded the markcfg7 file from the vendor.

My other lenses, I loaded the original markcfg7 file, then loaded the cor file in the device settings.

Hope some of this made sense?

![]()