After pondering this, I think a fiber might not be a bad idea. As long as you understand the limit of doing or what you want to do… I’m not a expert, but I’ve run mine enough to know I still don’t know much…

I think the video was good and confirmed my suspicions.

I hoped you asked him about the thickness he uses and how long it took.

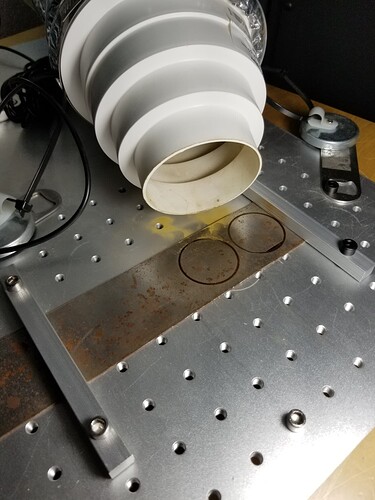

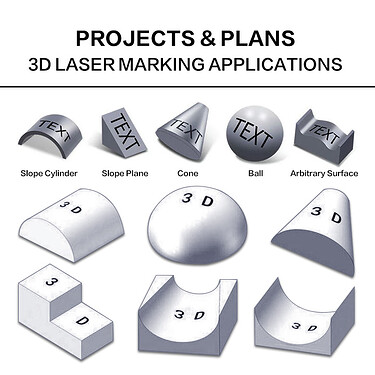

If you note, I stated you can do it also, but it takes lots of passes. I did a 3d coin that took 2 hours and is relatively deep. That was 256 passes in 3dslice mode.

The brass I cut was done in about 30 passes and it did distort. It was 1/2 the thickness of what you are after. 60 passes would be an easy task … but it will depend on the material.

Fiber lasers are fast for many things, but there are lots of passes a small interval to get the results you want, so it’s take time.

I doubt you’ll find actual disks the same size as you need. There are so many watch sizes… Am I incorrect in the observation?

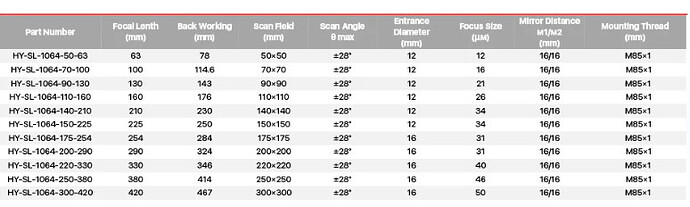

If you want to do a lot of cutting, then the bigger the better, wattage wise. I ended up with the 60W, but they are solid state pumped and triggered, they are pulse lasers.

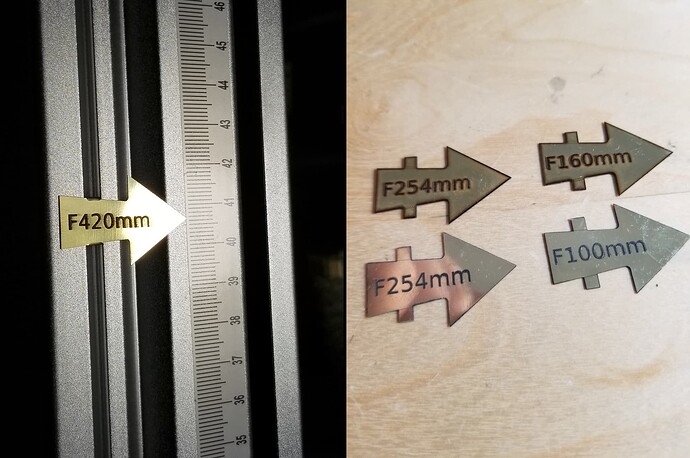

I’d suggest staying under 100W… the lenses for these go up by about 8 times.

Are these, that you are looking at a q-switch or mopa types? A mopa gives you much more control and is better than q-switch for oxidizing/annealing for a colors type visual result.

About 30:20 into the Sadler video he explains fiber lasers. The whole video (~1 hour) is a good watch if you don’t know how some of the works.

For coins, mostly I use a circle engraved out that will seat the coin. It’s pretty shallow. If I move anything on the machine or table, I just do another one…

Good luck… keep us informed.