Hello I have a little problem with the cutting in Lightburn

(In photos you can see…)I give to cut 350mmX25mm and this when I take is 347mmX24.22mm this happens always

Maybe we have a solution for this?

Try edit > machine settings calibrate axis at bottom.

Ok thanks i try this later…

I make this but is the same

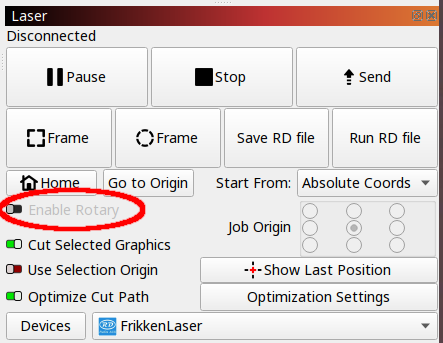

If changing the calibration didn’t change the axis distances, particularly on the Y axis, then perhaps the Rotary Enable switch is turned on:

It’s all too easy to hit that switch by accident!

If you don’t have a rotary, you can remove that switch:

The X axis is close enough to be accounted for by the cut width. Do your measurements take into account that kerf?

An earlier discussion may provide some pointers;

I like ‘Calibrate Axis’.

Calibration results are more accurate when comparing the finest line possible to the known shape. Cutting straight through introduces kerf, directional properties of the material

and can exaggerate any asymmetry in the laser dot.

Because axis calibration is linear, introducing errors like kerf into the axis calibration will increase or decrease the error as the size of the project changes.

Kerf shouldn’t change with the size of the project.

Please engrave a faint square 400mm x 400mm on any material to test the accuracy of the machinery and perform the axis calibration. When the machinery moves as expected, the next step is to apply kerf (the width of the cut) to the project that is sent to the laser. Generally, the path of the laser is moved one half of the width of the cut away from the piece you intend to keep.

With the axis calibration complete, cut the square out of the target material. If you have a square that is undersized, increase the kerf offset by 1/2 of the error. The width of the cut is half into the square and half into the discarded material. The square is two line-halves undersized. The kerf offset is 1/2 the width or one of the half widths. You may want to adjust kerf last if the output isn’t symmetrical.

If you still have a significant difference between the X and Y axes, rotate the material 90 degrees and perform the cut again.

- If the error moves, it’s caused by the material.

- If the error doesn’t move it’s caused by the shape of the laser dot,

- If the error is significantly different between the two squares, either better or worse, the dot shape and the material may both be to blame.

I hope this helps you divide and conquer your settings.

Hi @Kostas1967 I would like to confirm if the mismatch between what you designed and laser cut is consistent? Lets say you cut the 350mm x 25mm five times do you always end up with 347mmX24.22mm or does it change?

Always the same…

In that case, please do the following:

-

Use the .dxf file (Calibrate Axis File.DXF (43.2 KB)) to cut on the the material of your choice. Ensure that the model is placed such that X on the model is aligning with X axis of the machine.

-

Measure the X and Y lengths

-

Edit - Machine Settings - Calibrate Axis

Calibration Axis - X

Requested Distance - 25

Actual Distance - ________ ( Measured X length, just number will do no need of adding units)

Click Write

Calibration Axis - Y

Requested Distance - 25

Actual Distance - ________ ( Measured Y length, just number will do no need of adding units)

Click Write

-

Try cutting the same file once again and check the measurements,

If it still needs fine adjustments repeat steps 1, 2 and 3.

ORif it is perfect, try cutting a different geometry to check your results.

thanks everybody about the answers i fint the solution all now is ok

spesial thanks @AshNi …

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.