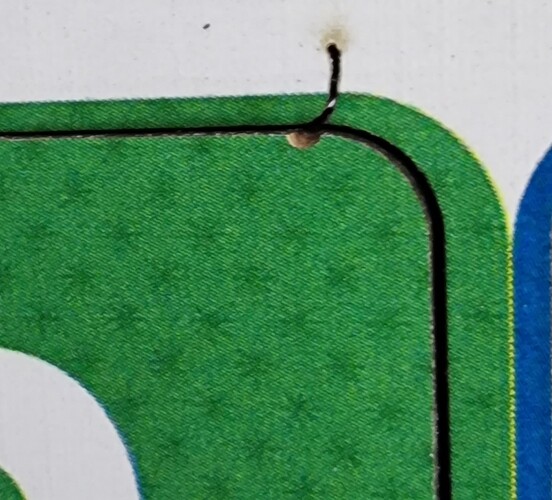

I’m getting a notch burnt into the endpoint of a 9mm MDF block that is cut at a slow speed, (7mm/s). It is caused when the polygon is finished and the piece drops slightly (the workpiece is slightly suspended) and the laser is still firing for a fraction of a second, making a mark on the fallen finished piece.

I solved this in RDWorks by entering negative 20 ms into the Close Delay parameter in the cut settings. Since switching to LightBurn, the problem has returned, and I’m finding the End Pause Time parameter will not accept negative numbers, stopping me from using this same solution.

Is there a work-around to get the same result in LightBurn, essentially telling the laser to turn off or ease off at the end of a polygon?

I need to be able to apply it easily to many existing DXF files, so manually adding tabs to every end point will not work, and automatic tabs seem to only work from the middle of a line.

I’ve tried reducing the minimum power, at at some point that causes the whole job to not be cut correctly which is not what I’m expecting, I only want to affect the end point of the cut.