Folks,

I would like to share my initial results with laser “engraving” in color.

Being inspired by great NWT method - lack of color can be limiting to some creativity. I love B/W photography and know that b/w art is great. Color is just another dimension to the art. I had conversations if it is possible at all and heard skepticism if temperature necessary for this actually achievable with simple diode lasers. My earlier observations and calculations supported this possibility, that 2KC is achievable. Finally I’ve ordered bottle of ceramic glaze and tried it today. Just run simple calibration grid, picked what appeared best and most uniform fusion of the silica in glazing to the tile and run this burn presented here. Not much trial at all.

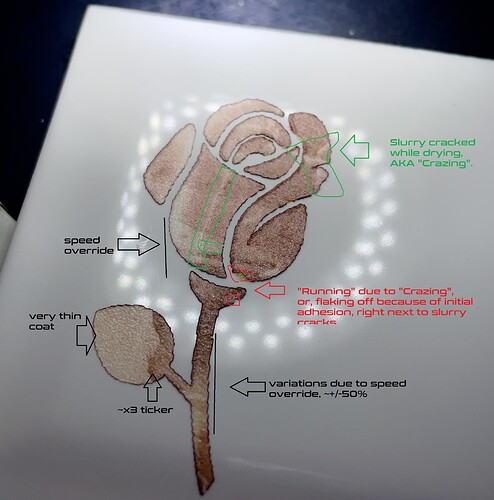

While sample below is full of defects, obviously, technically it is a robust demonstration of feasibility of creating color artwork on tiles with lasers.

What I did exactly:

Use this glaze.

Applied as received. I use paper float to smear it over tile. I did not thin anything. Slurry coat appeared pretty thick and cracked in many places while dried with heat gun. I did parched it with another coat as thin as I was able to smear for complete coverage.

Run cal grid on one tile. With my 4W optical - best was 100% at 425mm/min.

Then I got this burn:

That rose is 30x50mm

It is completely fused to the tile (well, little corner is not but I know why), feels as solid as glass (it is glass, I mean Silica).

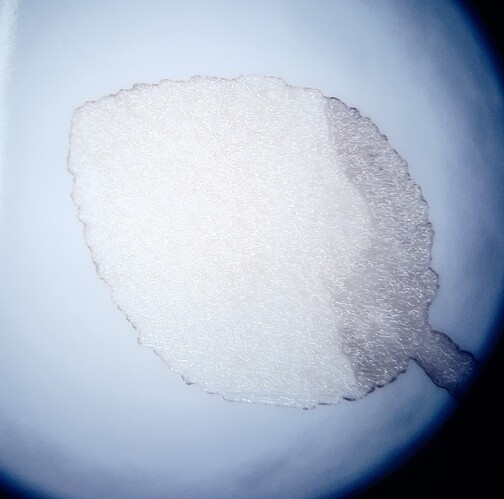

It has very interesting texture. Sand like but smooth.

Has very pastel color but this is expected. Most glazing requires x3 or more coats to reach desirable saturation. I did not try yet to do multiple coats/passes but I see no problem with it.

Perimeter appeared to have some black burn products. It is very flaky and most come off with tooth brush. It does not spoil fused areas. I do not think this is a big deal.

I guess biggest challenge here will be application of slurry. It feels like watered mud. It can be tinned with water. I will try spray on.

Technically this is neither, engraving nor burn. This is laser fusion. It is additive. But texture is very comparable to engraving. Pretty much all dried slurry is converted to glazing. (to compare - NWT most of material is burnt and small volume of TiO2 is diffused with Silica. Glazing leaves much larger added volume than TiO2 with white paint. But there are some similarities. NWT texture is significantly finer.)

Image below is after I use toothbrush with toothpaste trying to remove black edge. Some success.

I think this opens a lot of creative possibilities. Ceramics is an old art and a lot can be borrowed and learned from there.

I’m also thinking: after creating tile, it can be fired as other glazed ceramics.

I would love to see some folks with CO2 lasers able to replicate this. One of the challenges I see is heating coat of slurry to melt and at the same time tile below to fuse to it. On my test grid -cells with less power have glazing cooked but not adhering to the tile. CO2 IR goes deeper and I expect should be able to heat it more evenly, which in turn should yield better and easier fusion.

I guess I will order bottle of blue glazing and see what I can do with two colors.