I think you haven’t quite grasped what’s happening… takes a while… or I am not following you…

When a machine is moving across material, it’s referred to as the surface speed. Many machines will move the tool and the material simultaneously which, when combined gives you the concept of surface speed.

A simplistic example is, along one axes the tool is moving 100mm/s but the material is moving 50mm/s, so the surface speed, along that one axes could be 50mm/s (100 - 50) or 150mm/s (100 + 50).

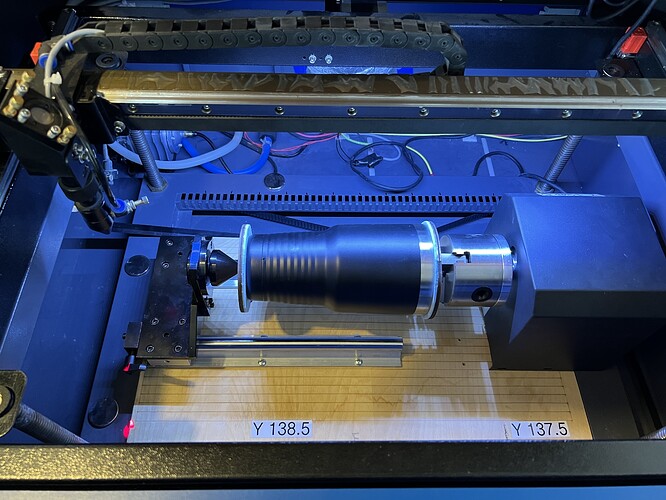

With a wheeled rotary the wheel is driving the surface of the object, the resulting surface speed of the object is that of the driving wheel, no matter the size of the object.

A chuck rotates an object around it’s center.

Cars have differentials because when you turn a corner or go in a circle, the inner wheels turn slower than the outer wheels… So with a chuck you need to know the diameter of the object to compute the surface speed…

If you chuck up a 55 gallon drum or a coke can, one rotation of the chuck will produce 1 rotation of the item… the distance around the 55g is much greater than the coke can, so the surface of the 55g drum must move faster to make one rotation in the same amount of time…

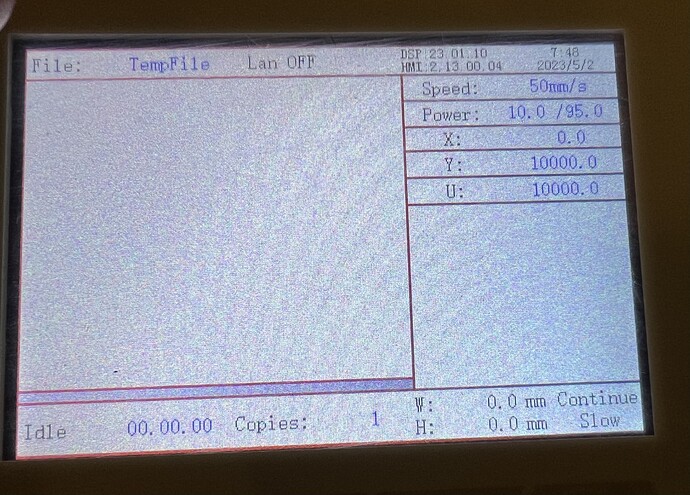

You’ll have to move the Y axes to a lower number… else it can’t travel any further than it’s max…

Use the Ruida console to move your indicated work axes (Y) to it’s center or at least the size of that direction of the artwork…

I hot swap my rotary and just run the Y axes up to 150mm half the area of the Y axes.

I use this work flow when doing mugs… The last batch had the manufacturers logo on the center front.

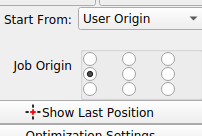

I set start from to user origin and center left for job origin.

If the mug is positioned with the logo up it should center the image on the mug relative to the logo… with the image going to the right… looks like how you set yours up.

Place the head at the bottom of the image area, on mine that right above the logo.

Press the origin key on the console

Run the job… hopefully I didn’t miss any steps but I’ve done this a bunch…

Make sense?