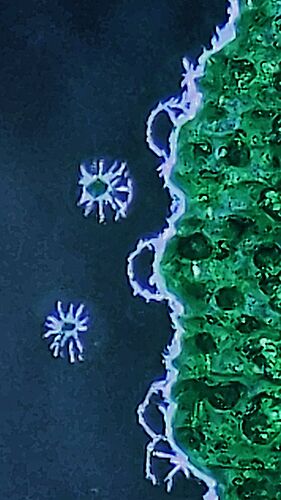

And, as a side effect, the alcohol in permanent markers cracks it like crazy, as seen in a mirror engraving I did:

The big green area had the mirror backing engraved away, then colored with green Sharpie: the border of the engraved area is full of stress cracks. The starbursts are random speckles punched through the mirror backing and, because my coloring hand is weak, they got Sharpie scribbled over them, too.

Pretty when seen through the microscope, but if it weren’t so cold out I should’a done a rattlecan paint job.