It seems everybody engraving acrylic with a CO₂ laser has seen random speckles appearing in places where the design shows a blank. Regardless of the suggested remedy in the many threads on this topic, nothing stops the dots.

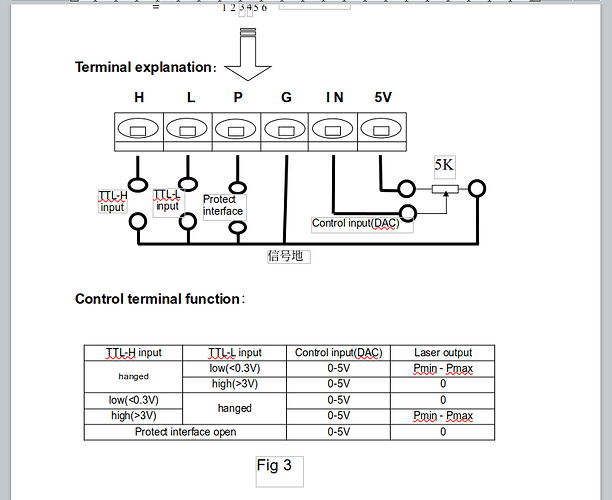

It turns out the problem lies inside the high-voltage laser power supply, which occasionally fires the tube at random, even though the controller has disabled the supply’s output. Although I’ve measured only two power supplies, other folks report random dots regardless of the CO₂ laser’s seller / brand / size / location, which suggests the same problem occurs in all of them.

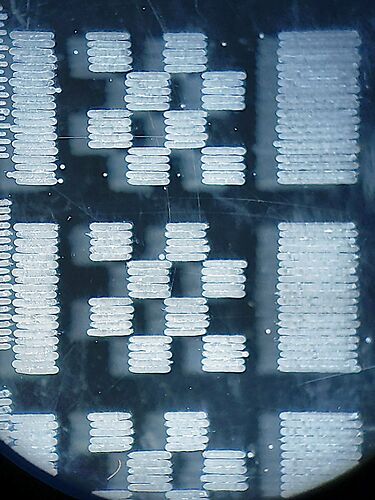

For example, this acrylic target has many spurious dots among its patterns:

The test pattern is very small, with the checkboard squares just 1 mm on a side:

It’s almost invisible at the center of the LightBurn file:

Pulse Timing Pattern - 1 mm blocks.lbrn2 (5.2 KB)

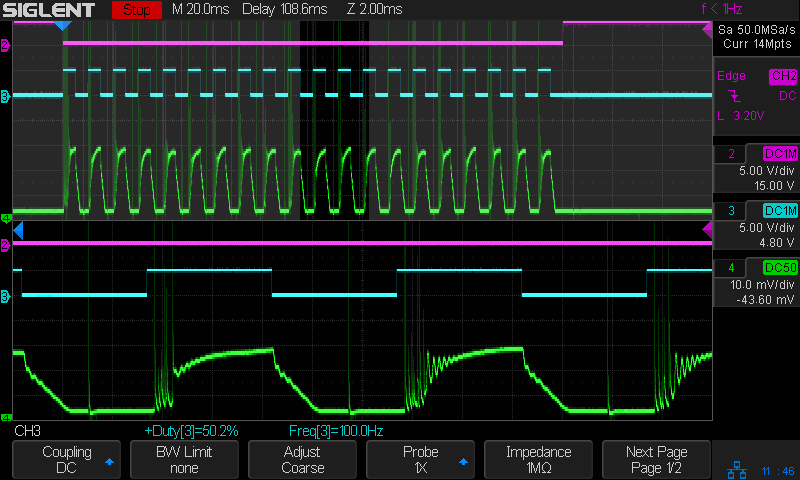

Engraving the pattern at 250 mm/s engraves each 1 mm line with a 4 ms laser pulse. The wider block has lines 2 mm wide, each of which lasts 8 ms.

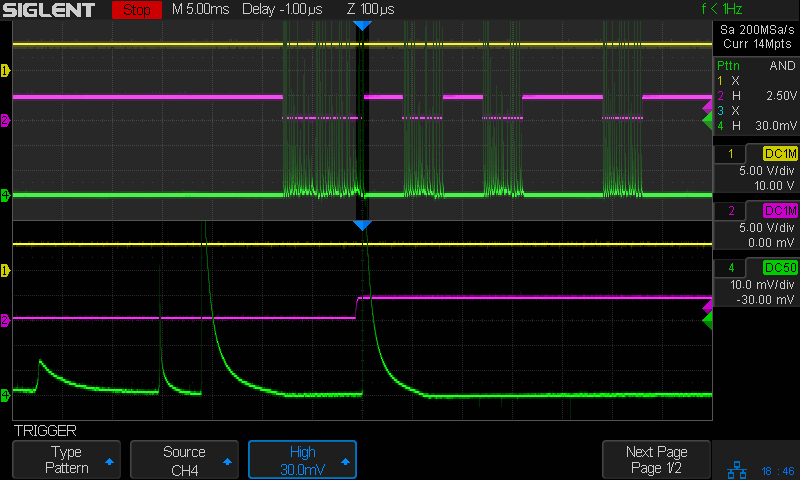

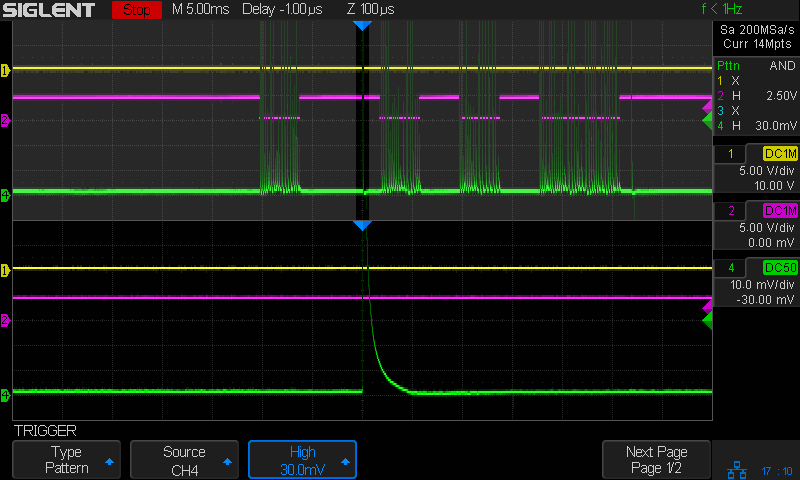

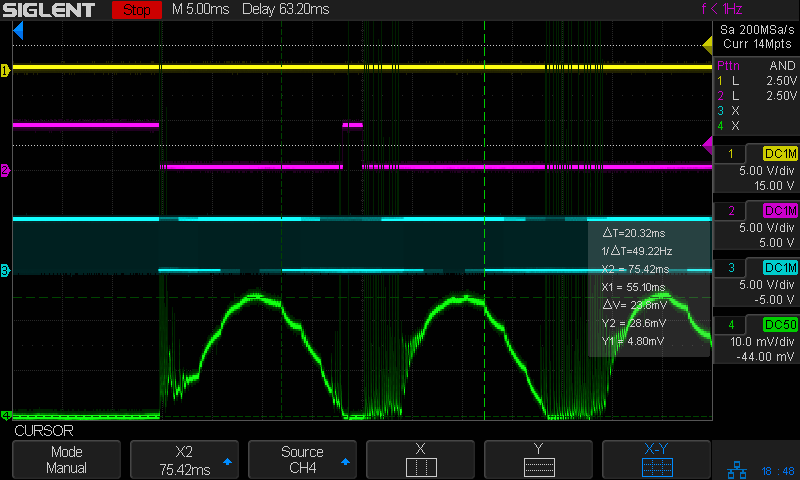

I captured the spurious pulse responsible for the dot just to the left of the block, six scans up from the bottom:

It occurred during a right-to-left scan, just after the controller disabled the power supply output at the end of the 2 mm line:

The upper half of the oscilloscope screenshot shows the entire scan across the pattern and the lower half is a greatly expanded view of the section just after the 8 ms pulse engraving the line.

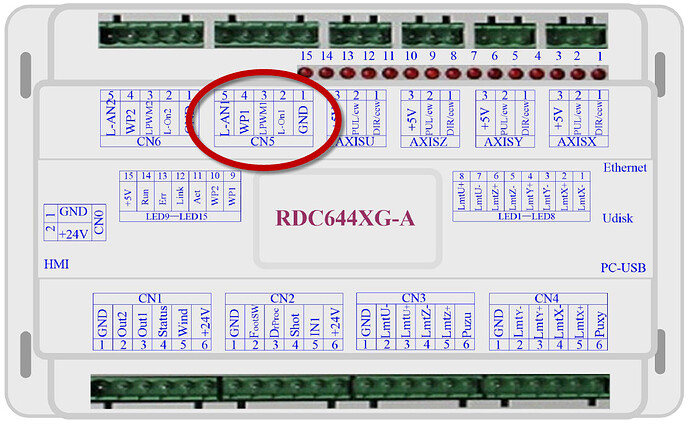

The magenta (purple!) trace is the controller’s L-ON signal, which enables the power supply output when it is low. It rises at the end of the 8 ms pulse, at the middle of the screen marked by the blue triangle: the laser should not fire.

The green trace shows the laser tube current, measured with a somewhat exotic Tektronix non-contact current probe clamped around the tube’s cathode (grounded!) wire, with a vertical scale of 10 mA/div. The spiky blips are what the power supply delivers for PWM values below about 25% on my supplies; a discussion of that mess could be a whole 'nother topic.

The somewhat lumpy texture of the scan line corresponds to the various pulse heights to the left of scope screenshot’s center, where the beam is engraving the 2 mm line. The other engraved lines show a similar texture, with the irregular timing of the spikes causing small variations in the length of the scans making up the bar.

The spurious pulse occurs 10 µs after the L-ON signal rises to disable the power supply output, producing the neat round dot just to the left of where the scan line should have ended.

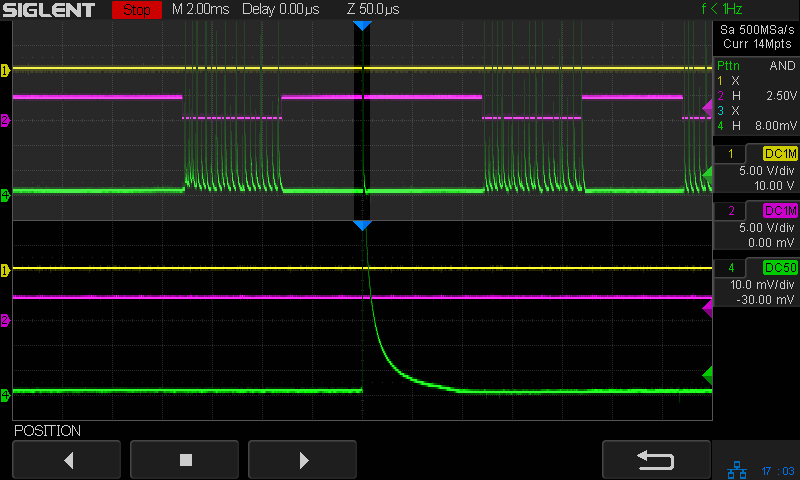

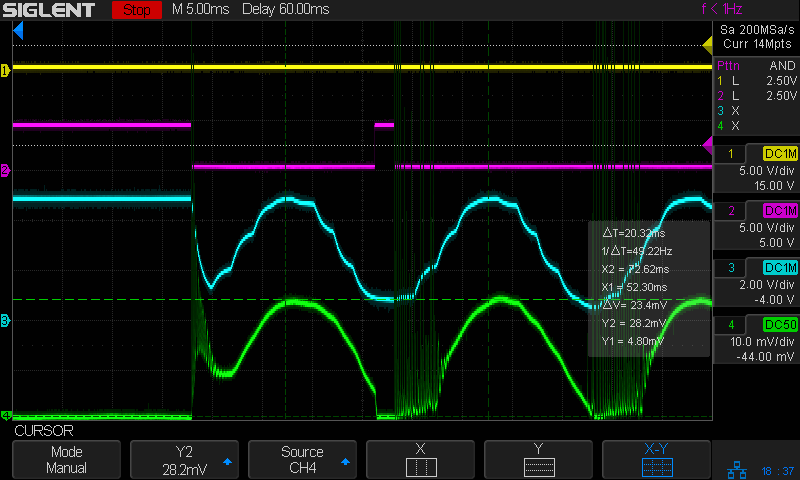

Setting the scope to trigger when L-ON is high (inactive) and the laser tube current is more than a few milliamps captured many similar glitches.

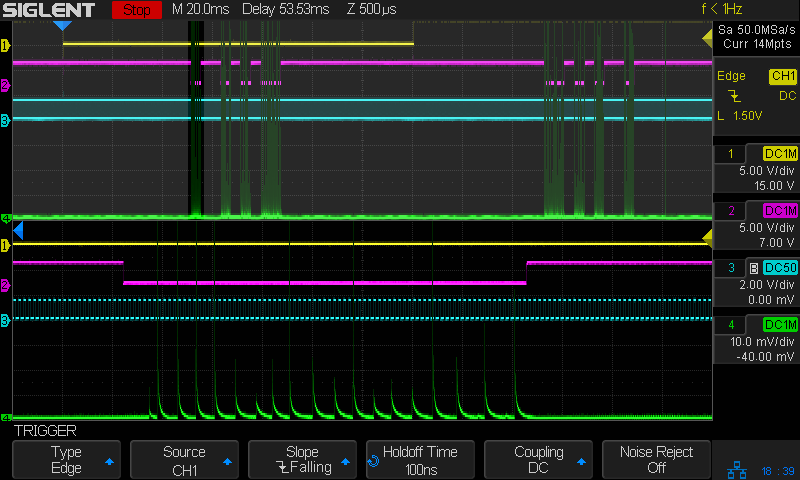

For example, this glitch happened in the middle of a blank section:

This glitch waited until just before one of the checkerboard blocks:

Each of those glitches produced a single dot in what should have been a blank section of the pattern, when the controller had disabled the laser output by raising L-ON.

Unfortunately, I don’t know of any way to prevent these glitches.

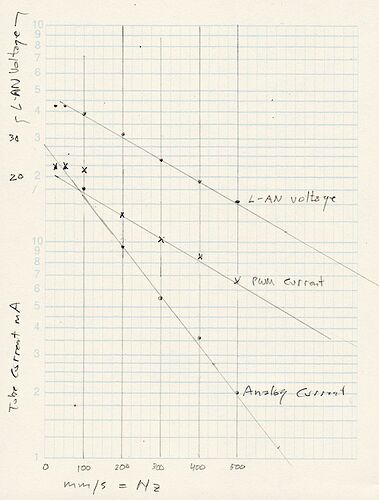

They seem to occur more often at PWM values below about 30%, where the power supply output is more chaotic, but they still occur at higher PWM. I think engraving with higher power at faster speeds should reduce the number of speckles, but I don’t have any measurements to verify that. You can engrave the tiny test pattern at different current levels to see how your power supply behaves.

A more complete writeup of these measurements, with linkies to all my background information & posts, is on my blog:

The first post in the series describes the test setup, so if you read forward from there you’ll get all the grisly details.