OK, Here you go. Too big to attach in any case. Put them up on one of my servers:

OMTech AF2435 80W (From web)

OMTech AF2435 80W (inc with machine)

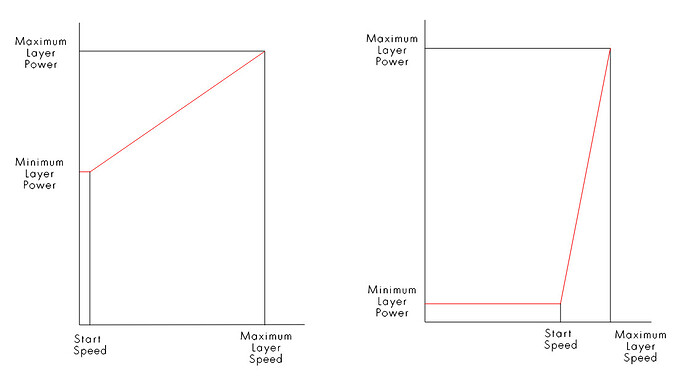

The specific power ratings (ma vs percentages) is listed in both the above manuals. From my understanding, it’s not strictly a linear relationship (ma vs %Pwr). IOW: I don’t think you can simply take 20% off the 100% power rating (ma) and assume its 80%… I guess it comes down to the relationship between Electrical Power and Beam Power.

Check page 18 on the manual included with the machine and note that the values are slightly different in the power table in the other document.

The rotary dial on my laser is located on the left side. It’s some sort of an attenuator which allows manual control of the power going to the tube. This apparently sits between the controller and the laser. So even if I send a job at 100% and set my controller to allow 100% (99% actually) I can actually turn down the manual adjustment to ANY power value I want. By doing this, I can effectively define 100% to be anything I want (like 23ma). This way, I can set a job to cut at “100%”, set my controller to allow 100% (99% actually), and make it all correspond with “100%” of what I deem to be my personal operating maximum = 23ma (rather than the ACTUAL 100% of tube capacity).

The attenuation knob does allow full attenuation (all the way down to fully off). I can rotate the knob while a job is running and watch the beam fade and extinguish and then bring it back up again. So I set a test job to run at 100%, have my controller set to allow 100% (99%), and then just adjust the knob until I see 23ma (per the tables). Done.

The only downside I see here is if the knob somehow gets tweaked by mistake. I’m looking at 3D printing a fixture to hold the knob at my desired set point so it isn’t subject to being disturbed by mistake. Unless my adjustment gets tweaked, there is no way my machine will ever run at anything higher than 23ma.

Curiously, neither manual discusses what the meter/knob is called or how it should be used. But it definitely does provide manual control of the beam power and it will scale the power accordingly (as indicated by both the power meter and the beam intensity itself)

If you look at page 4 on the manual from the web, you can just make it out in the top photo on the upper left side of the machine.

It seems more natural for me to be able to work with cutting powers which scale to 100% (instead of limiting just to 70% or 80%). I’m confident I’m getting a power I can feel comfortable with (23ma when I request 100%). It’s just a matter of whether some other considerations further down the road (like conflicting with community traditions) will change my opinion on this…