The motors don’t have anywhere near that much torque! Steppers make a horrible sound when they can’t produce enough torque, but it’s harmless.

With the power off, move the gantry by hand from front to back a few times while noticing what happens:

-

It should move smoothly without much effort and no abrupt sticky spots.

-

There should be no odd sounds at any point, particularly when reversing directions.

If it doesn’t move smoothly or you hear (or feel) anything odd, figure out what’s causing the problem. It could be an accumulation of crud in the linear slide rails, a chunk of debris caught in the belt, or a loose fitting in all the shafts & pulleys between the motor and the belt.

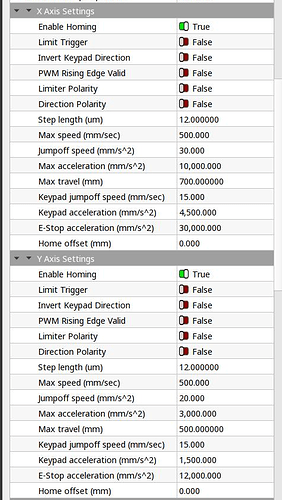

With the power on, use LightBurn to examine the speed and acceleration for the Y axis. There is no reason for those values to change without notice, but it’s worth checking. They should be close to these:

If all those tests pass, then the debugging gets a bit trickier. Report back with the results!