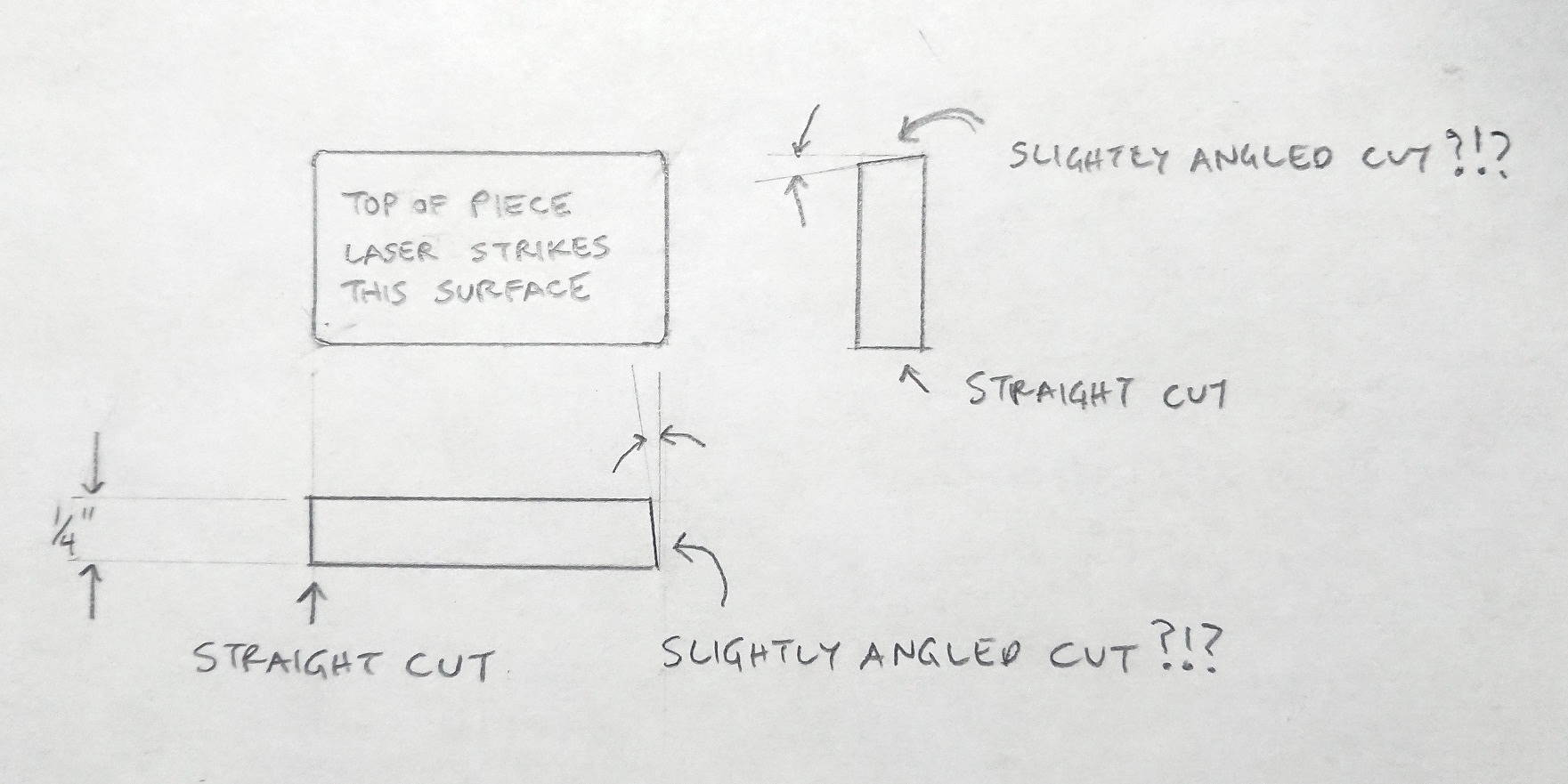

I am cutting a small rectangle out of a 1/4" thickness acrylic. Two sides of the cut piece are at a slight angle (suggesting that the laser is it hitting it an angle) whereas the other 2 sides are perfectly square (suggesting the laser is hitting it perpendicularly).I am at a loss to explain how this could happen. See attached drawing showing the finished piece. I am focusing the laser in the middle of the material. Any insights?

I would check the surface the acrylic is laying on to be sure it is perfectly parallel to the the x axis rail. If the work surface dropped a few mm from the left side to the right side you would see that happen.

It’s possible that the nozzle isn’t pointed straight down.

Move the table up close to the nozzle and zap a piece of cardboard or something. Now move the table down 6" and zap again. If the 2 marks aren’t concentric then the nozzle isn’t pointed exactly downward.

My red&black was off quite a bit when I got it.

Thank you for the drawing. If I am interpreting it correctly, your drawing illustrates the angled finished edge occurring on perpendicular sides (which would plausibly eliminate an out-of-plumb lens holder being the reason).

If the angled edge was on parallel sides or all sides, good sign of needing a lens holder alignment.

How are these edges affected or changed when you move about the table? Try testing four small squares each at or near the corners and compare the edges.

Maybe improper (uneven if two) belt tension or unequal belt lengths on Y?

I am in brainstorming mode… But the lens is probably the point I would start at. Using a longer focal length is much more forgiving and will provide for straighter edges if you get to a point of futility.

If your bed is not level / plumb to the gantry, you will see this problem with angled edges due changes in focus (especially pronounced on shorter focal length lenses).

everything mentioned above is all valid. I had a similar problem and mine turned out to be the laser tube was not correctly leveled in relation to x/y axis rails making adjustment using mirrors impossible. The net result was slopping cuts on both axis.

I have the same problem and have just had the service man come to find out why, with no luck.

My problem is very slight

My mirrors were correctly aligned and the cut appeared perpendicular,was this the same as your case?

Nev

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.