Dear Mike Hembrey

Never have I requested compensation.

If you laser head wobbles, move slower.

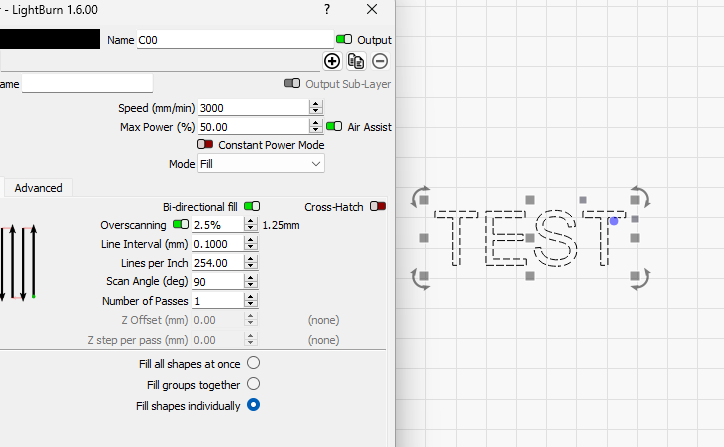

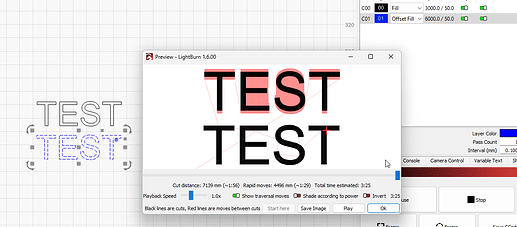

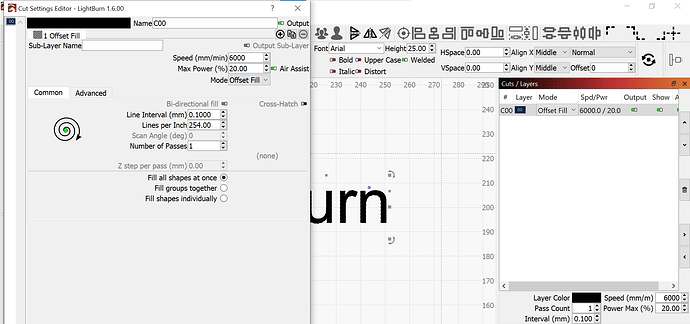

Movement in the X axis alone produces a better finish then movement in both X & Y axis on cheap machines due to poor design & build.

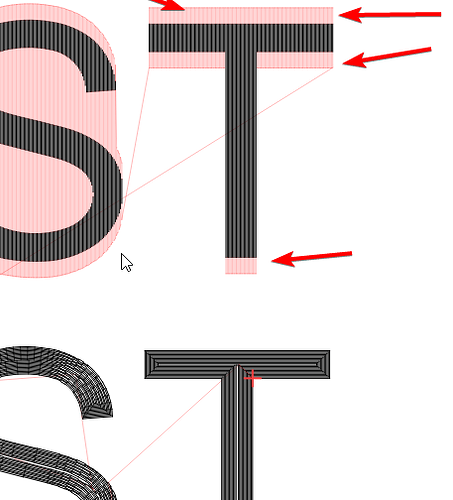

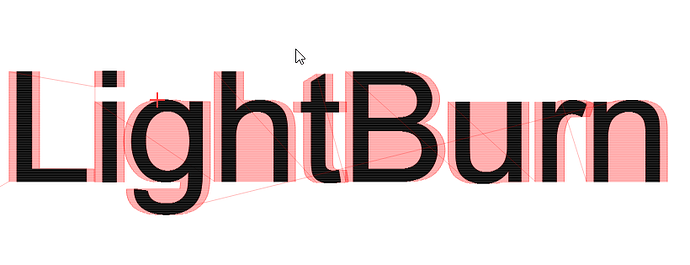

Aliasing occurs when a digital imaging system (such as a camera or a computer screen) fails to accurately represent high-frequency signals or patterns. When diagonal lines are digitized, especially at certain angles, they can produce jagged or stair-step-like artefacts due to the limited resolution of the digital representation. This phenomenon is often referred to as “jaggies” and is a form of aliasing. So, in essence, digitizing diagonal lines can indeed result in aliasing artefacts.

When you’re trying to represent a curve using straight lines (a process known as linear interpolation), especially in digital graphics or computer-aided design (CAD), you essentially approximate the curve by connecting a series of straight line segments. This process is often called “polygonal approximation” or “polygonal representation.”

However, because curves are smooth and continuous whereas straight lines are not, there can be discrepancies between the true curve and its polygonal representation. This can lead to aliasing artefacts, particularly if the curve is not sampled finely enough or if it’s displayed at a low resolution. So, in a way, aliasing can occur when representing curves using straight lines due to the inherent limitations of digital representation.

Your statement “Nyquist does not apply here” is actually false…

Nyquist-Shannon sampling theorem, a fundamental principle in signal processing, is indeed applicable in computer graphics, particularly in areas like texture mapping, anti-aliasing, and image resampling.

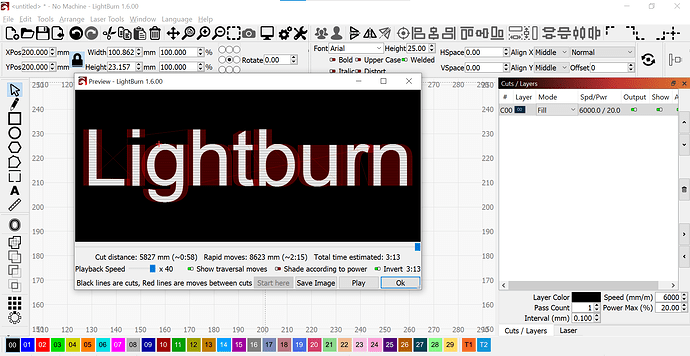

Anti-Aliasing

Anti-aliasing techniques, such as super-sampling and multi-sampling, rely on the Nyquist-Shannon theorem to smooth out jagged edges in rendered images. By sampling at a higher rate than the display resolution and then averaging the samples, these methods reduce aliasing, adhering to the principle that the sampling rate should be at least twice the highest frequency present in the signal (image).

Image Resampling

When scaling images up or down, the Nyquist-Shannon theorem informs the filtering process to avoid aliasing. Techniques like bilinear or bicubic interpolation use the theorem to determine how to sample the original image appropriately, ensuring that the resampled image maintains quality without introducing artefacts.

Practical Considerations

While the theorem provides the theoretical basis, practical implementations often deal with challenges like computational efficiency and hardware limitations. Modern graphics hardware and algorithms incorporate optimizations to balance quality and performance while adhering to the principles of the Nyquist-Shannon theorem.

The Nyquist-Shannon sampling theorem is integral to various aspects of computer graphics, ensuring high-quality visual output by guiding proper sampling techniques to avoid aliasing and other artefacts.

Regards

Mark