Let’s be serious. They are speaking of the paper not a wooden item.

I CUT paper all the time in my laser. So do thousands of other users. Paper masking is used by 10’s of thousands of laser owners every day.

Yes indeed, I am not yet terrified of my lasers setting fire when I cut paper

The tape you are referring to is known in the sign trade as “application tape” and unless you have it sitting up off the surface (with an air gap between it and the underlying material), the laser will not ignite the tape. It can also be dampened after application if needs be. The only other problems you may have are if you are using low power, you may leave the adhesive as a residue on your work surface and the other is when you have to “weed” the tape from finished intricate lettering or work.

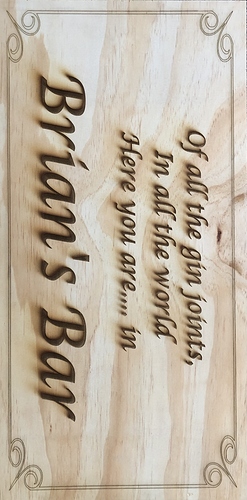

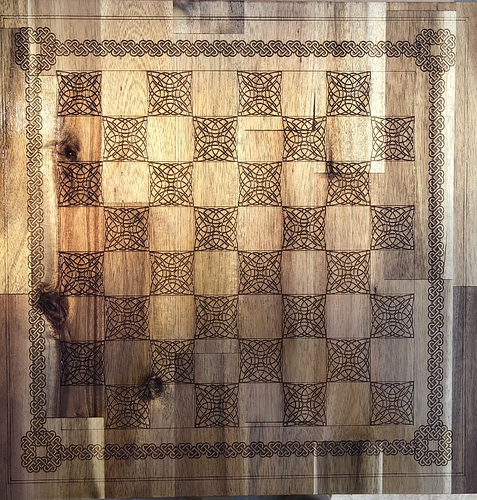

I am having a lot of fun using various timbers to experiment. I have just finished a chess board on 25mm (1 inch) finger jointed acacia and a bar sign on marine ply for a neighbor. I have deliberately directed the smoke across the work and sprayed clear polyurethane to give it a 3D look.

So I am new to laser etching, may I ask why people use tape when laser etching items?

To prevent smoke marks among other such things on the engraved item.

Clever. I like it!

The chess board is nice engraving but the finger jointed wood (AKA timber) is too busy and, IMO, takes away from the piece.

If the glued-up pieces are done well the very small amount of joint showing adds to the dimension of the wood. Making it appear as it is, natural wood, not plastic or laminate.

We have done thousands of feet of glued up panels over the years. We have many pieces of machinery making many things possible, including a wide belt sander.