Hello,

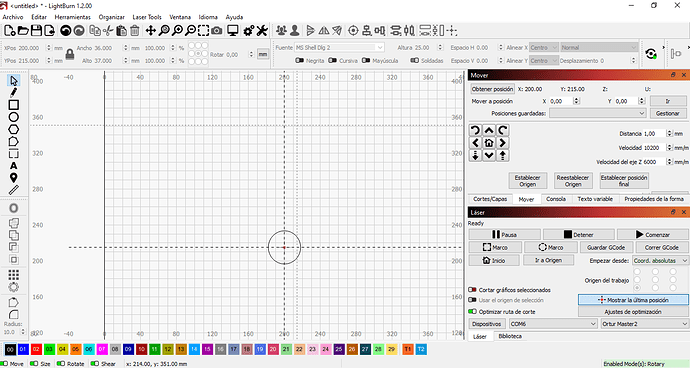

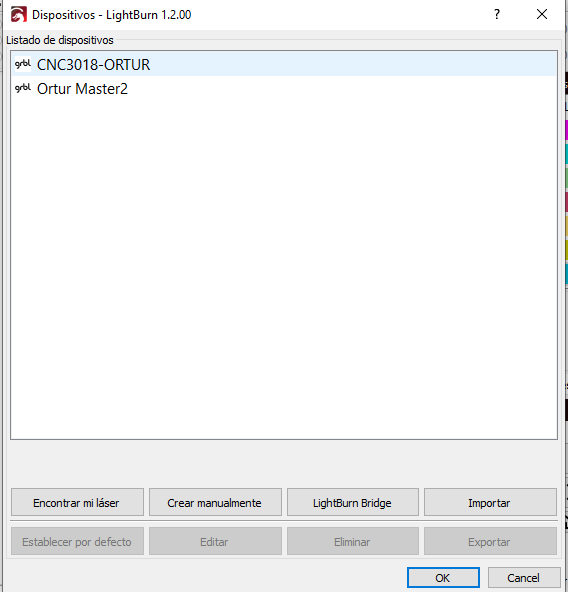

I have an ortur master 2 machine, with an alarm when trying to execute a code.

I did the firmware update few days ago.

I have also tested with LaserGRBL and it works without problems.

ALARM:2 G-code motion target exceeds machine travel. Machine position safely retained. The alarm can be unlocked. (Right click on the 'Devices' button to re-establish connection) At or near line 4: Job stopped Transmission completed at 0:00

[MSG:Reset to continue]

ok

Ortur Laser Master 2 Ready!

OLF 142.

Grbl 1.1h ['$' for help]

[MSG:'$H'|'$X' to unlock]

[MSG:Caution: Unlocked]

ok

$$

$$

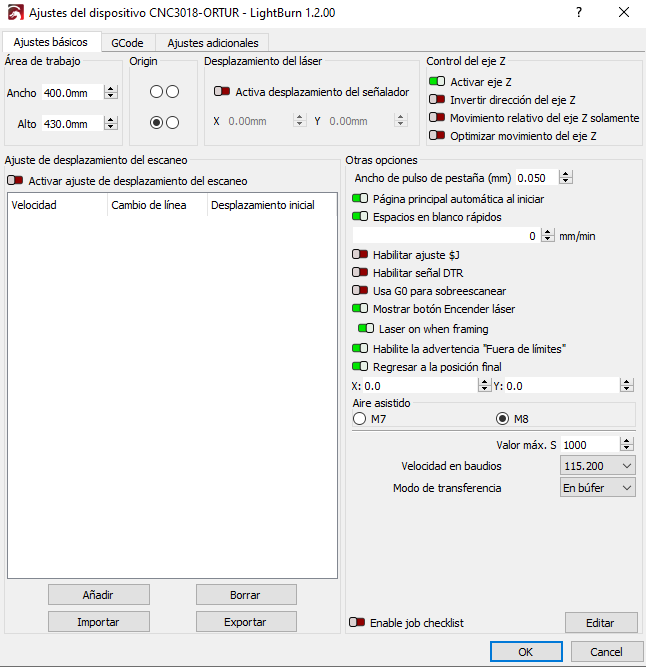

$0=2.000

$1=25

$2=0

$3=0

$4=0

$5=0

$6=0

$10=3

$11=0.050

$12=0.002

$13=0

$20=1

$21=1

$22=1

$23=7

$24=600.000

$25=3000.000

$26=100

$27=3.000

$30=1000

$31=0

$32=1

$33=500.000

$50=0

$51=0.000

$52=0.000

$100=80.000

$101=80.000

$102=80.000

$110=9000.000

$111=9000.000

$112=1200.000

$120=2200.000

$121=1800.000

$122=2500.000

$130=400.000

$131=430.000

$132=1.000

ok

$#

$#

[G54:0.000,0.000,0.000]

[G55:0.000,0.000,0.000]

[G56:0.000,0.000,0.000]

[G57:0.000,0.000,0.000]

[G58:0.000,0.000,0.000]

[G59:0.000,0.000,0.000]

[G28:0.000,0.000,0.000]

[G30:0.000,0.000,0.000]

[G92:0.000,0.000,0.000]

[TLO:0.000]

[PRB:0.000,0.000,0.000:0]

ok

I’m trying to make a circle

GCode Generated

; LightBurn 1.2.00

; GRBL device profile, absolute coords

; Bounds: X182 Y196.5 to X218 Y233.5

G00 G17 G40 G21 G54

G90

M4

; Cut @ 2000 mm/min, 1% power

M9

G0 X192.994Y2268.384

; Layer C00

G1 X192.196Y2272.629S10F2000

G1 X191.42Y2277.311

G1 X190.666Y2282.415

G1 X189.936Y2287.929

G1 X189.23Y2293.84

G1 X188.55Y2300.133

G1 X187.897Y2306.796

G1 X187.272Y2313.816

G1 X186.676Y2321.178

G1 X186.11Y2328.87

G1 X185.576Y2336.879

G1 X185.074Y2345.19

G1 X184.606Y2353.791

G1 X184.172Y2362.669

G1 X183.775Y2371.81

G1 X183.415Y2381.2

G1 X183.092Y2390.827

G1 X182.809Y2400.677

G1 X182.567Y2410.738

G1 X182.366Y2420.994

G1 X182.207Y2431.434

G1 X182.093Y2442.043

G1 X182.023Y2452.809

G1 X182Y2463.718

G1 X182.023Y2474.628

G1 X182.093Y2485.394

G1 X182.207Y2496.003

G1 X182.366Y2506.443

G1 X182.567Y2516.699

G1 X182.809Y2526.759

G1 X183.092Y2536.609

G1 X183.415Y2546.236

G1 X183.775Y2555.627

G1 X184.172Y2564.768

G1 X184.606Y2573.645

G1 X185.074Y2582.247

G1 X185.576Y2590.558

G1 X186.11Y2598.567

G1 X186.676Y2606.259

G1 X187.272Y2613.621

G1 X187.897Y2620.64

G1 X188.55Y2627.303

G1 X189.23Y2633.597

G1 X189.936Y2639.507

G1 X190.666Y2645.021

G1 X191.42Y2650.126

G1 X192.196Y2654.808

G1 X192.994Y2659.053

G1 X193.811Y2662.849

G1 X194.647Y2666.182

G1 X195.501Y2669.039

G1 X196.372Y2671.406

G1 X197.259Y2673.27

G1 X198.16Y2674.618

G1 X199.074Y2675.437

G1 X200Y2675.713

G1 X200.926Y2675.437

G1 X201.84Y2674.618

G1 X202.741Y2673.27

G1 X203.628Y2671.406

G1 X204.499Y2669.039

G1 X205.353Y2666.182

G1 X206.189Y2662.849

G1 X207.006Y2659.053

G1 X207.804Y2654.808

G1 X208.58Y2650.126

G1 X209.334Y2645.021

G1 X210.064Y2639.507

G1 X210.77Y2633.597

G1 X211.45Y2627.303

G1 X212.103Y2620.64

G1 X212.728Y2613.621

G1 X213.324Y2606.259

G1 X213.89Y2598.567

G1 X214.424Y2590.558

G1 X214.926Y2582.247

G1 X215.394Y2573.645

G1 X215.828Y2564.768

G1 X216.225Y2555.627

G1 X216.585Y2546.236

G1 X216.908Y2536.609

G1 X217.191Y2526.759

G1 X217.433Y2516.699

G1 X217.634Y2506.443

G1 X217.793Y2496.003

G1 X217.907Y2485.394

G1 X217.977Y2474.628

G1 X218Y2463.718

G1 X217.977Y2452.809

G1 X217.907Y2442.043

G1 X217.793Y2431.434

G1 X217.634Y2420.994

G1 X217.433Y2410.738

G1 X217.191Y2400.677

G1 X216.908Y2390.827

G1 X216.585Y2381.2

G1 X216.225Y2371.81

G1 X215.828Y2362.669

G1 X215.394Y2353.791

G1 X214.926Y2345.19

G1 X214.424Y2336.879

G1 X213.89Y2328.87

G1 X213.324Y2321.178

G1 X212.728Y2313.816

G1 X212.103Y2306.796

G1 X211.45Y2300.133

G1 X210.77Y2293.84

G1 X210.064Y2287.929

G1 X209.334Y2282.415

G1 X208.58Y2277.311

G1 X207.804Y2272.629

G1 X207.006Y2268.384

G1 X206.189Y2264.588

G1 X205.353Y2261.255

G1 X204.499Y2258.398

G1 X203.628Y2256.031

G1 X202.741Y2254.167

G1 X201.84Y2252.819

G1 X200.926Y2252

G1 X200Y2251.724

G1 X199.074Y2252

G1 X198.16Y2252.819

G1 X197.259Y2254.167

G1 X196.372Y2256.031

G1 X195.501Y2258.398

G1 X194.647Y2261.255

G1 X193.811Y2264.588

G1 X192.994Y2268.384

M9

G1 S0

M5

G90

; return to user-defined finish pos

G0 X0 Y0

M2

Sometimes he throws this at me

G90

; return to user-defined finish pos

G0 X-30.335 Y-7.911

M2

As I understand it is launching very high values at the beginning and negative values at the end of the job.

Any help or background on how to solve it, I’m very grateful.