As long as the lens is still secure?, a loose focus lens will cause poor results. I wonder if you are getting enough air flow? Instead of trying to move the nozzle closer you may want to consider upgrading your air supply especially if you are primarily cutting MDF and wood products. A decent flow of air is needed to clear away the smoke and residue and allow the beam to penetrate better.

The power fluctuation will only really happen in the very last few mm leading in and out of corners - where it is needed, so for cutting generally the Min should always be lower , to whatever looks best for the corners and still cuts through, try about 30-40% less e.g. 60/85

Have you tried going much slower like 12mm/s with 50%min and 60% max power?

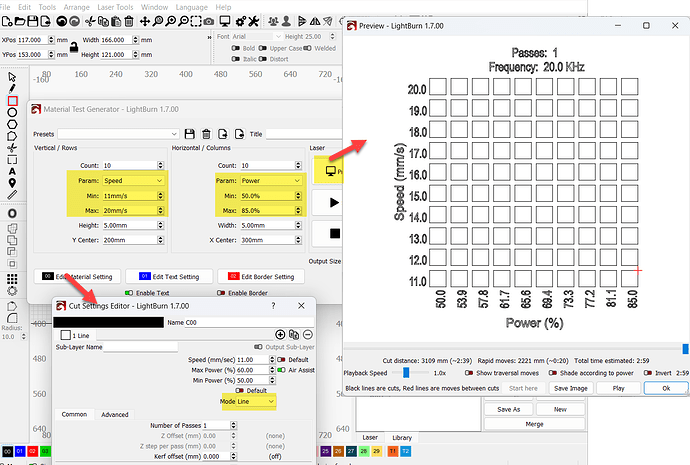

Have you tried a wider range of speeds and powers using the material test?

For example:

Try focussing to the surface of the material instead. MDF has a harder skin due to the heat pressing process so it’s more important for the laser to quickly break through that top skin to allow the beam time to get through the rest of the material.

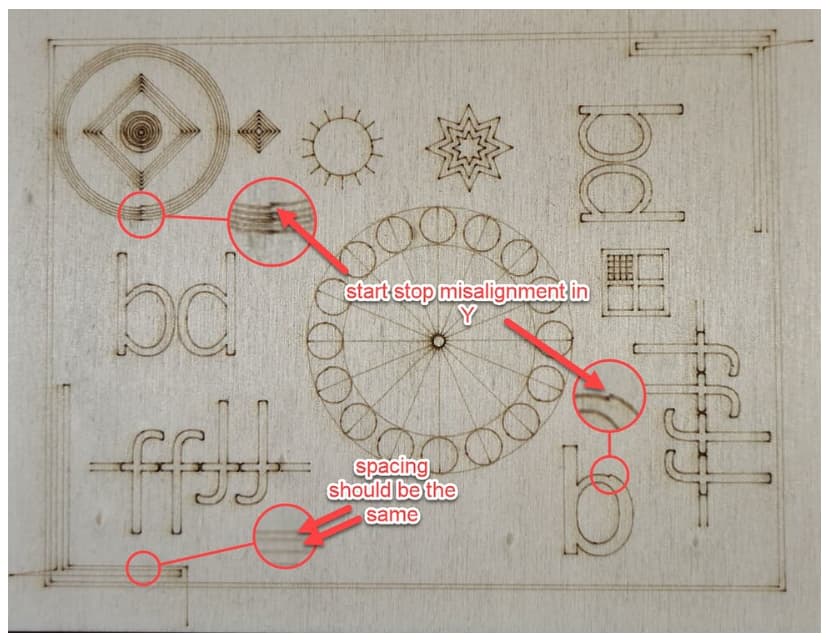

Regarding backlash, the test file attached here is good at showing backlash issues and which axis are involved (please disable ‘Optimise Cut Path’ for this test):

Test.lbrn2 (73.5 KB)

The pic below is an example of what the test result looks like, in this case from a machine which exhibited some noticeable backlash in the Y-axis;