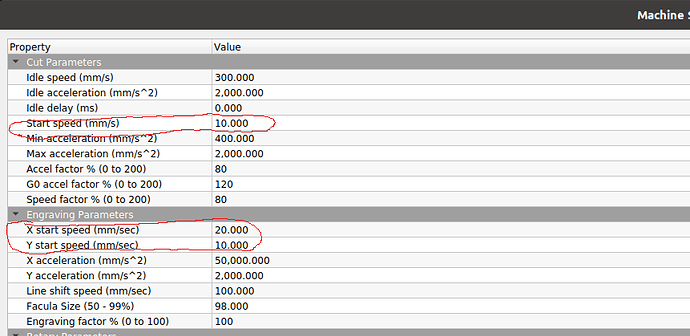

Yep, Jack gets it. “start speed” and “min power” are dead ends.

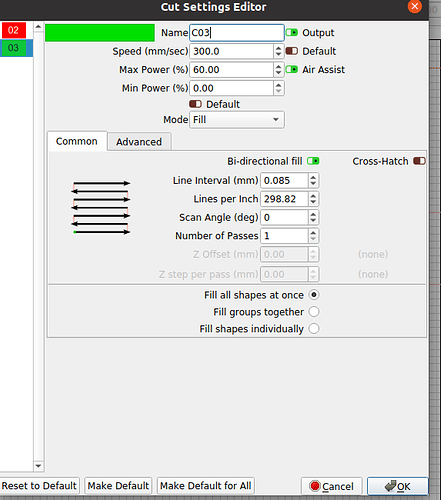

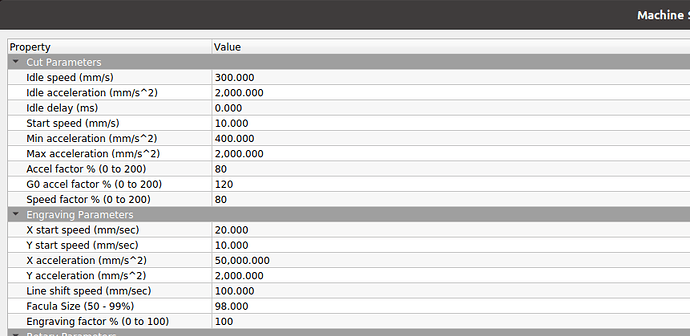

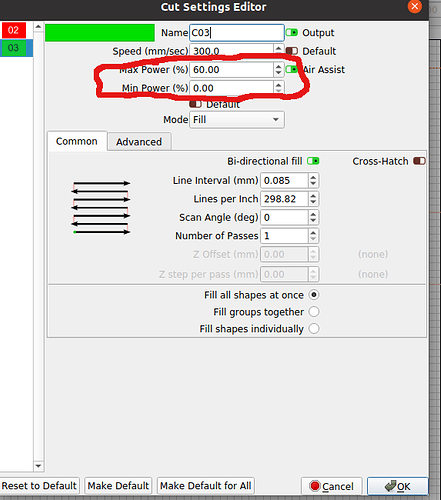

The basic expectation would be that a controller, in dynamic accel not constant velocity (start, stop, hitting corners) would throttle the laser proportionately based on ratio of instantaneous velocity over target velocity. e.g. 100mm/s 100% max power/1min power, when it’s accelerating and only at 20mm/s actual, the laser would be at 20% of max. If you gave 80 max and 20% min power, you’d get 32%, since that’s 20% of the scale.

But, it appears not. They weighted it in a nonlinear way, boosting the lower % range, for… reasons, like monitor gamma. And there’s no way to override or adjust it to something else. PWM freq won’t change anything, it’s the duty they’re coming up with.

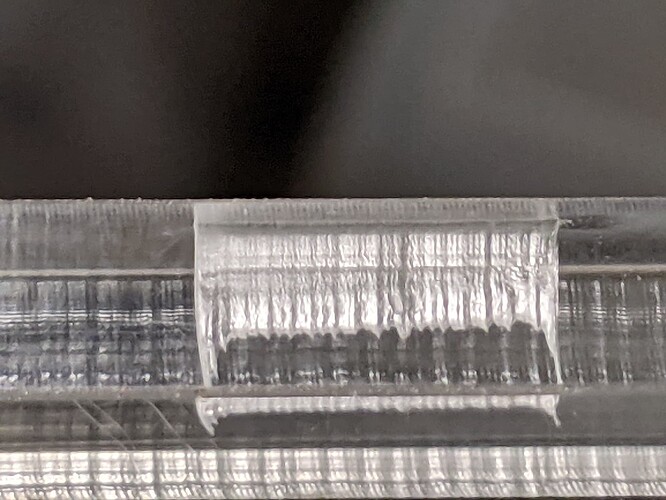

Can you achieve a cut through? Yeah, this nonlinearity won’t even matter, actually, for cut through. It just overpowers these spots. It does not weaken the constant velocity portions.

It’s in vector engraving, it’s inconsistently applying overpower in curves. This is clearly apparent on acrylics. I’ve accidentally punched all the way through plywood on vector text corners.

“min power” is 1%, setting anything higher would the wrong way for dynamic acceleration adjustment. It would push the power higher on the proportional side, not lower.

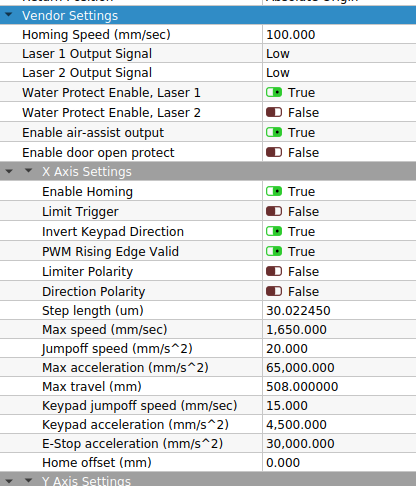

“Start Speed” just clips the power until a certain speed. That could prevent something from being cut, but once it starts, the overpower is still right there.

e.g. as per prior example, 100mm/s target speed and instantaneous velocity is currently 20mm/s, I’m apparently getting more than 20% PWM. We could say “start speed= 15mm/s”, well, then there’s no vector cut before this. From there, I’m unclear if 20mm/s is going to be the same calc, or it offets the calc over and instead of being 20% of target v it calcs like 5 of 85 of the target? That actually could be better sort of, but still nonlinear and creating a major new nonlinearity.

We never used it, but at least one of our Universal Lasers had a power correction table for interpolation. As best I understood it, it has entries for each 10% interval, and this is how much to reduce the beam from target power when below target velocity. By default, 10% of target speed is 10% duty of target PWM duty and we never changed from that and get consistent depth of partial-thickness vectors in acrylic across start/stop/corners. Maybe a teeny tiny underpower bit at the start because it doesn’t have a start dwell to preheat the first 0.05mm.

It looks like Ruida has such a correction chart, but it’s hardcoded, and hardcoded to something nonlinear.