I’m not sure if I can post this here or not, but I could really get a good start business-wise if someone could answer this question. I have a friend who wants to make a book, and they have some drawings they want etched or engraved for the book. My question is, is there such a material that I can use to fulfill their idea? Or is that a no-go? As I mentioned, this could really set me off in a good direction, and I’d like to try if possible. Many thanks in advance.

You can engrave on paper… A laser is much like a printing press, it only really does a burn or no burn… The separation between different shades of gray is difficult to reproduce… especially on paper.

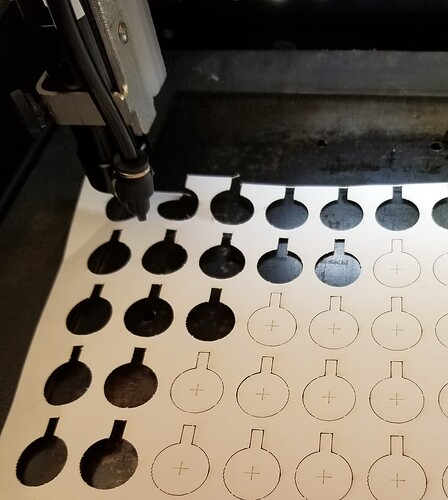

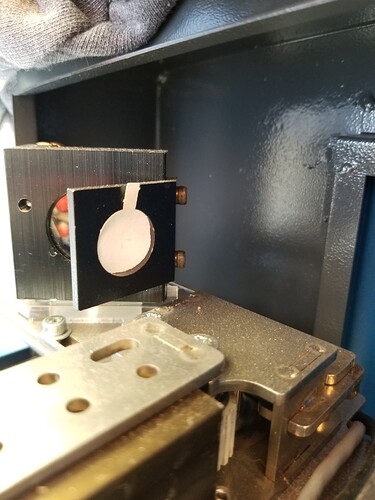

There is also the possibility of burnt edges… I do this on my co2 when I cut out targets for alignment…

I do this on watercolor paper, because it’s easier to handle when I put the target in the hole…

Remember the range is much smaller… Vector engraving is quickest, but photo type work is possible.

Good luck

![]()

Thanks is their any particular paper I should use ? Like thickness ect

The game is really materials…

I use watercolor paper because of it is more heavy and sticks in the target area I’m using…

The more thin the material, it can sometimes induce other issues… such as handling or getting it to stay put when lasing. I have a sheet steel table, I use magnets to secure the material.

Paper is cheap… so find the one that works best for you…

If you have a printer, use some of that paper… if it doesn’t work, there is Amazon and Walmart. ![]()

![]()

I use cardstock a lot for testing a lot of jobs its about 180-220gsm I think.

If you’re working with a blue diode laser, a paper that absorbs blue light would be a wise choice.

Some of the highly processed cardstock is a bright Blue-white and it can be reflective enough to make it a challenge to get adequate settings to mark or cut fine lines and stop before making excessively dark marks or unwanted holes in the work.

You’ll also need an art fixatve to prevent smudging the carbon residue on this type of work.

If your theme permits, you may want to consider a paper manufactured in a yellow through tan color. For single copies you could test with paper darkened with Tea or dye to get an appreciation for the difference in performance, behavior and settings required for your laser.

A CO2 laser will probably work better for Bright white cardstock.

yes, white can be hard to work with, I have found only one that works well, but generally use Mid to Dark Pastels for the majority.

Oo thanks my dad ordered white water color paper gsm 150 should he cancel it and order differently

I’d suggest you add it to the test material items. I have good results with it for my targets…

Many times you don’t find out about this stuff until you try it… understand what’s happening at the material level and you’ll be good.

![]()

Buying 2 or 3 of a kind at an art supply store may serve you better than a ream of untested material.

Your dad may have just ordered the best paper to use. You won’t know until you try it.

That is true it could be good paper he ordered ill just have to wait and see i do appreciate the advice and information from everyone

Don’t be afraid to try different materials… most you can google and get some idea about…

The only thing that should be scrutinized is if the material, when vaporized, can damage you or your machine…

Good luck

![]()

I have a 100W Co2 laser and can drop the power low- like 0.01% and raise the speed and it will make as fine as a light brown mark/line/design on plain copy paper. Just mess around with all the variables. Paper is a cheap material to learn on! Have fun. Gary

I know of no dc excited co2 laser that works at such low power settings…

What allows yours to reduce power so much?

Usually they stop lasing around 10% and as the power goes up, could be as high as 20% before it lases.

If it’s cold out, mine will lase at a little over 9%… it is inconsistent at these levels.

Which of their machines to you own?

![]()

My Power Max and Min can be set to 1 and 0, also I have a variac type switch on the machine that goes from min to max. Which makes it even weaker. Probably not good for the machine and Ive only done that twice trying to etch a inside cover of a book for a friend. For cutting 1/8"/3mm acrylic I set max power to 15 and min power to 12 and speed is good at 0.5" per sec.

I have a CamFive CMA1200 its around 10 years old, and uses SmartCarve for the program. Gary

What kind of machine allows this?

The only machines I’ve seen that will come near this are RF excited in the co2 market, at least for hobbyists.

What is this supposed to do? How does it work?

I’m thinking of a voltage variac… same animal?

I have a 40W same 3mm acylic cut 13mm/s@80%…

I think for your machine you should be running faster with more power… I’d expect better results… with this change.

![]()

I really don’t know much about technology!! If I go higher power and faster cut it seems to be less smooth on the edges, so I worked out the best finish by using the least power I could. Maybe thats the wrong way to do it! If theres a way to add a pic I could show you the voltage switch it has. G

Also, with 15% power It cuts at 12.7mm per second

Generally speaking, most lasers seem to cut most materials better at a higher speed with the highest comfortable power level…

In the end it ends up being what does the best job as far a speeds/feeds…

What model of machine do you have, or is this a secret?

![]()