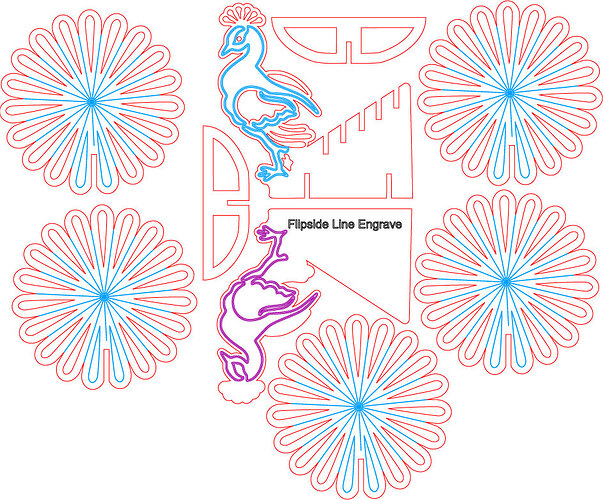

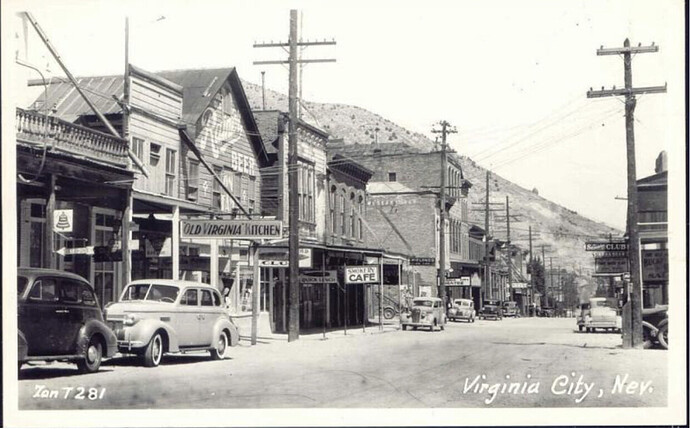

Peacock Coasters, fun project, but the stand has strength issues. Side note: the mug in that pic is the last remaining object from a gourmet coffee shop we designed and operated 45+ years ago in Virginia City Nevada.

That’s such an amazing idea!

Very cool. Thanks for sharing!

Cutting file peacock attached

peacock coatersb.lbrn (2.7 MB)

Love this…

Thanks, I attached the cutting file, so if you did not see on page

peacock coatersb.lbrn (2.7 MB)

Love your creativity and love this side note just as much. I love true history.

Biggest, richest mining town — Virginia City, Nevada

Cheers

![]()

Sas

I,m Very new to the forum only been burning for 4 months a change form the cnc I do like the peacock project. LesB

Thank you, let me know if I can be of help learning

Just wanted to thank you for sharing your Lightburn file. With just a little modification I used it to make a top for my wooden incense burner that I turned from some wood that I had. I first turned the base then from 1/8" pieces of veneer, I used the coaster part of your file to burn the top. The burner on the left is from white oak and the top is walnut. The burner on the right is cherry as is the top. These were fun to make and your file saved me a great deal of time. Again, thanks.

Looks great, thank you for letting me know.

I love the look of these, just a few questions - what thickness of material, Why is part of the lower peacock no output and what does “flip side engrave” mean

Thanks Martin

Material .120 thickness, If you are talking about the bottom of the flipside, the cuts are made on the first cut. The flip side is removed, the first cut is flipped and placed in that hole and detail engraving is created so the bird has detail on both sides.

remember to clamp the panel so it does not move to keep alignment.

Understood, thanks for the reply