I am using an Atomstack A10 pro, can anyone tell me how to calibrate it to cut perfect circles. Iam creating projects that need etching on both sides, when turning the material over it doesn’t drop back into the circle i’ve just cut, meaning it’s not a perfect circle, anyone got a fix.

Might help.

Thanks i’ll give it a try, nothing to lose.

Thanks for this, I did a calibration test and found it was out in the Y axis by 0.1mm, nothing to really worry about, circles still not coming out round, thin it’s more to do with the fact the head is belt driven and there is some play somewhere when doing circles, square cutting seems perfectly ok.

Can you take a photo of the circle? Even with belt systems circles should burn perfectly round to the eye.

0.1m is bigger than a kerf. It would matter.

When you said “turning the material over”, are you meaning that you flip the work piece over so the exposed side when cutting becomes the bottom (unexposed) side? I’m wondering if perhaps your laser is not perfectly perpendicular to the material so you are getting a very slight wedge effect that doubles up with the flipping of the material.

Yes, the material is being flipped, so I can burn the underside. Circles used to be fine in the past, its only recently that they are visably not round.

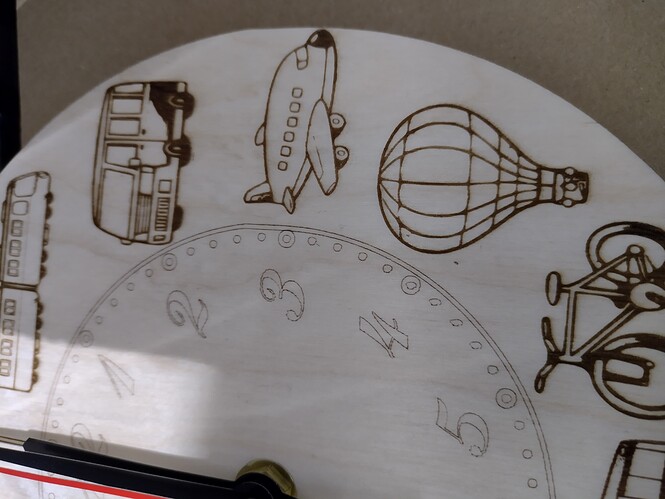

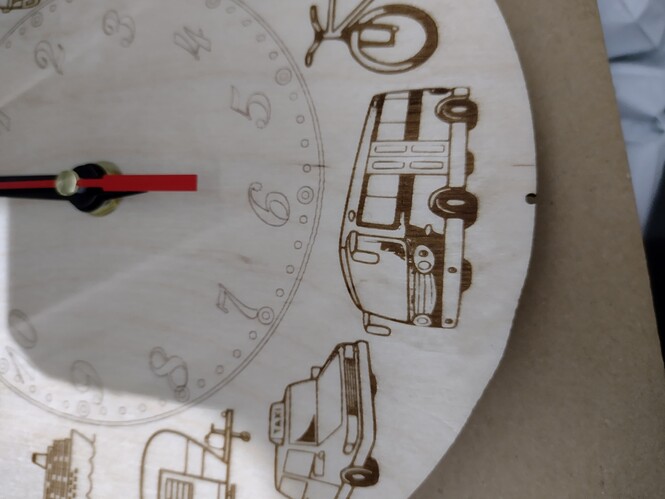

Find attached, 2 clock faces, produced one after the other, burnt in the same position. At the 7 area you can see oscilation on both the inner and extreme outside circles, and then also between 2 and 5 there is a definate flat spot at 3 again inner and outside areas, the small markers 4 to 5 area aren’t even round in one of the faces compared to the other, the job requires me to flip the work so that the back can be etched with customer details, because there not completely round they wont drop back into the outer frame, so I can index the reverse side work.

This seems like something mechanical to me.

Check belt tension, pinion gears, and wheel distance to railing. Make sure there’s no slop and also not overly tensioned. I see some other artifacts that might be caused by the same issue.

That was my thoughts as well, given the differences between to two parts, seem odd it should go off all of a sudden.

Parts can get loose or worn over time. Belts can stretch. Grub screws that are not fastened with thread locker have a tendency to work themselves loose over time with vibration.

It’s not at all uncommon so wouldn’t spend too much time worrying about how if it does prove to be something mechanical.