The correct dpi/lpi settings is critical for not only a good engraving, but also any fill operation.

Limiting factor is spot or focused dot size. Most co2 lasers, stock, usually are around 0.10mm (254 dpi). A compound lens would get you down to the 0.05mm (504 dpi) area…

The other half of the equation is how the material reacts to the damage by your laser.

You didn’t mention what kind of speed/power you are using… I have a 40W, I run it in the lower teens, power wise and keep the speed below 300mm/s… This is basswood, pretty soft…

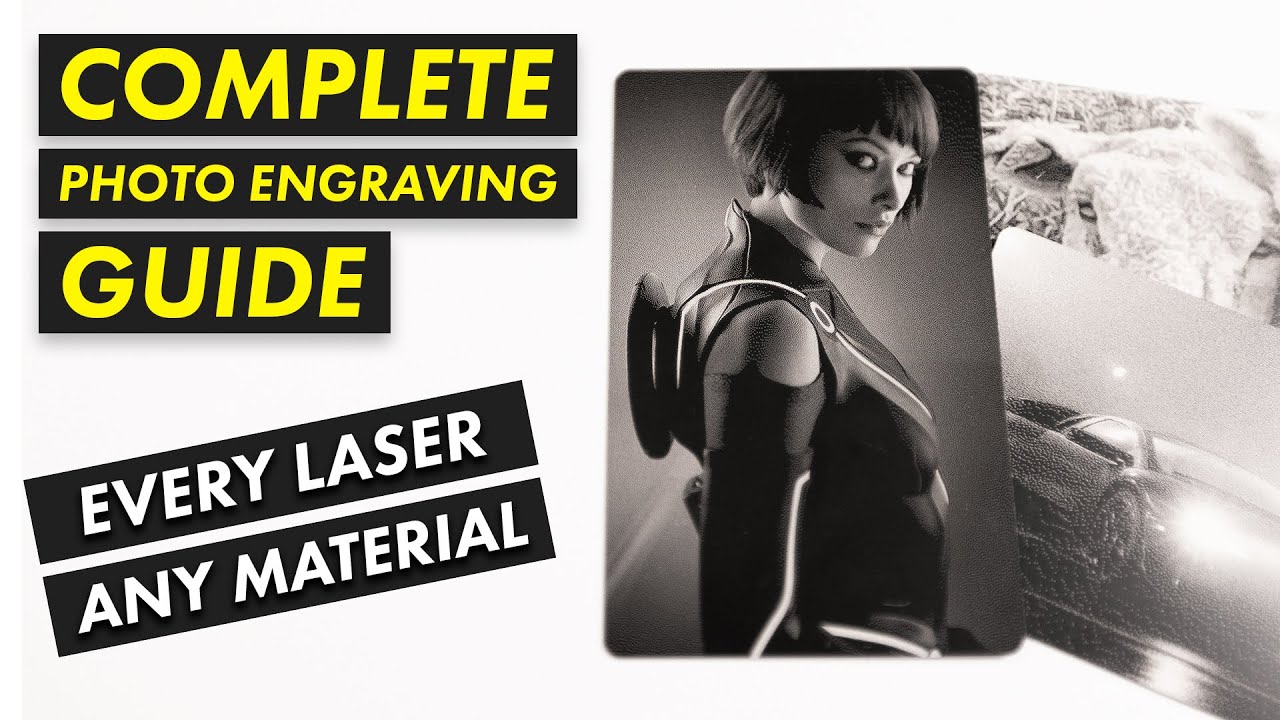

Spend some time learning how to get the correct dpi/lpi for your application… Laser Everything has an excellent video on this and the procedure works with any laser using any material… You’ll use this your entire lasing life…

Yes, but I’ve never done it with anodized aluminum cards and the co2. Only on my fiber. The video uses them.

@Bulldog is an expert with all types of materials… Both cards and the Norton tile method…

This is one of the most challenging uses for a laser…

Good luck

![]()